Completely-degradable polylactic acid composite material with high crystallinity and preparation method thereof

A composite material, high crystallinity technology, applied in the field of high crystallinity fully degradable polylactic acid composite material and its preparation field, can solve problems such as damage to polylactic acid biodegradability, low crystallinity, etc., achieve easy operation, improve Effects of crystallinity, improved heat resistance and gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

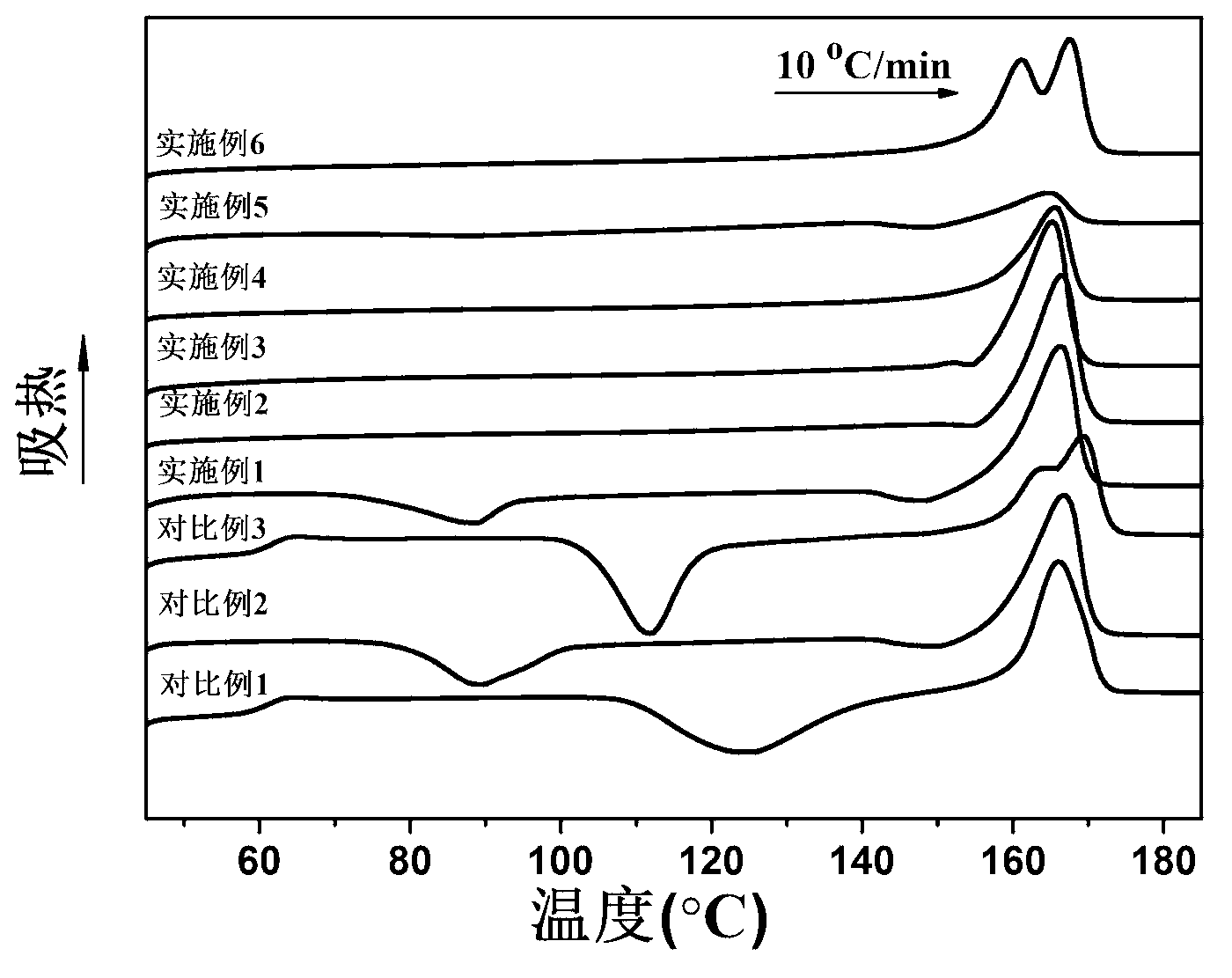

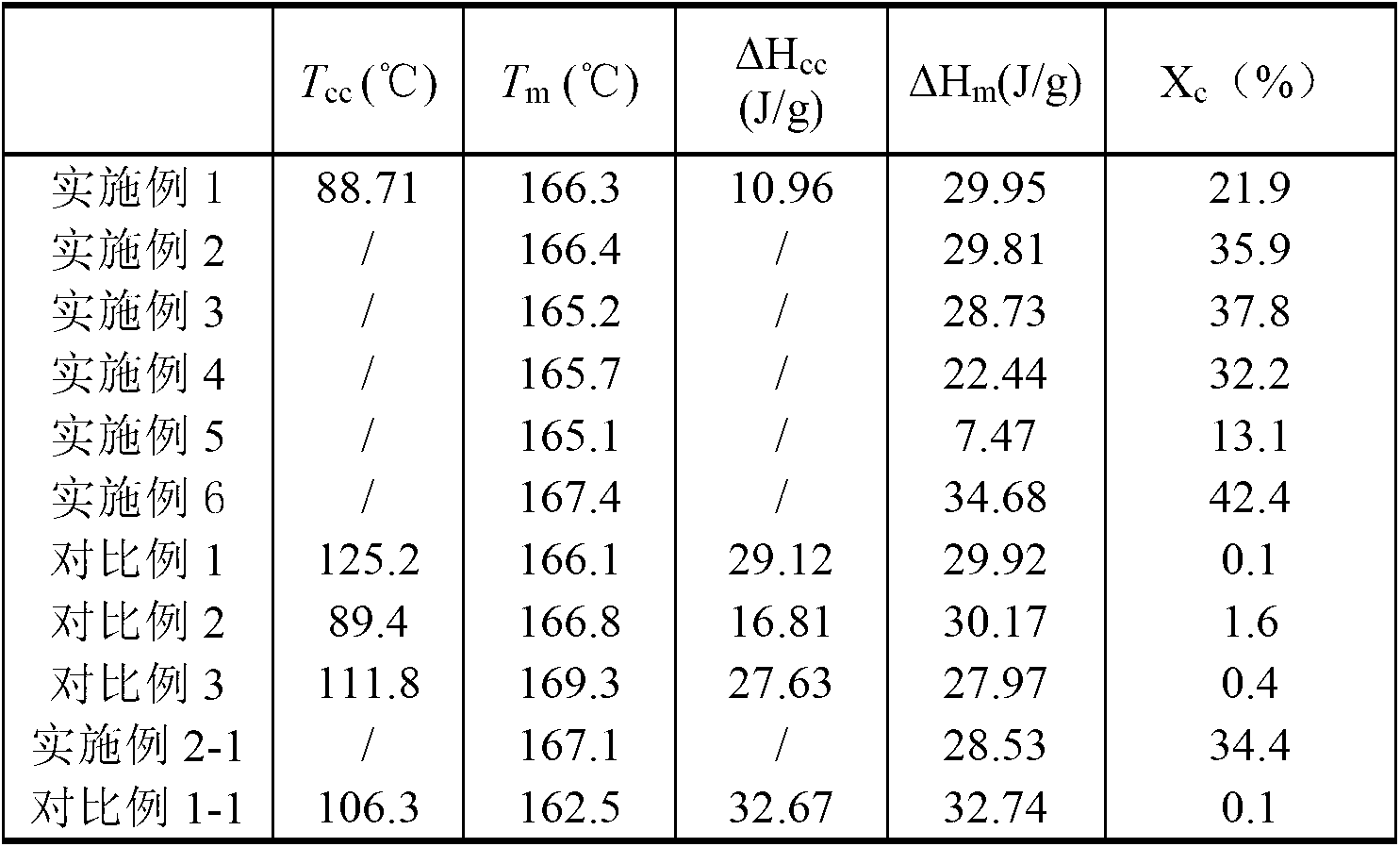

Embodiment 1

[0028] (1) Add 10g of poly-L-lactic acid to 100ml of dichloromethane solution at room temperature, stir for 3h; stand for later use; add 0.1g of poly-D-lactic acid to 10ml of dichloromethane solution, stir for 3h; stand for later use; Add 0.5g of polyethylene glycol to 10ml of dichloromethane solution, stir for 3h; stand for later use;

[0029] (2) Add all the poly(D-lactic acid dichloromethane solution) and the polyethylene glycol dichloromethane solution prepared in step (1) into the poly(L-lactic acid dichloromethane solution), and stir for 3 hours;

[0030] (3) The solution prepared in step (2) was left to stand at room temperature for 48 hours, and the solvent was evaporated to remove;

[0031] (4) The product obtained in step (3) was vacuum-dried at 50° C. for 48 hours to obtain a poly-L-lactic acid / poly-d-lactic acid / polyethylene glycol composite material sample with a ratio of (100 / 1 / 5).

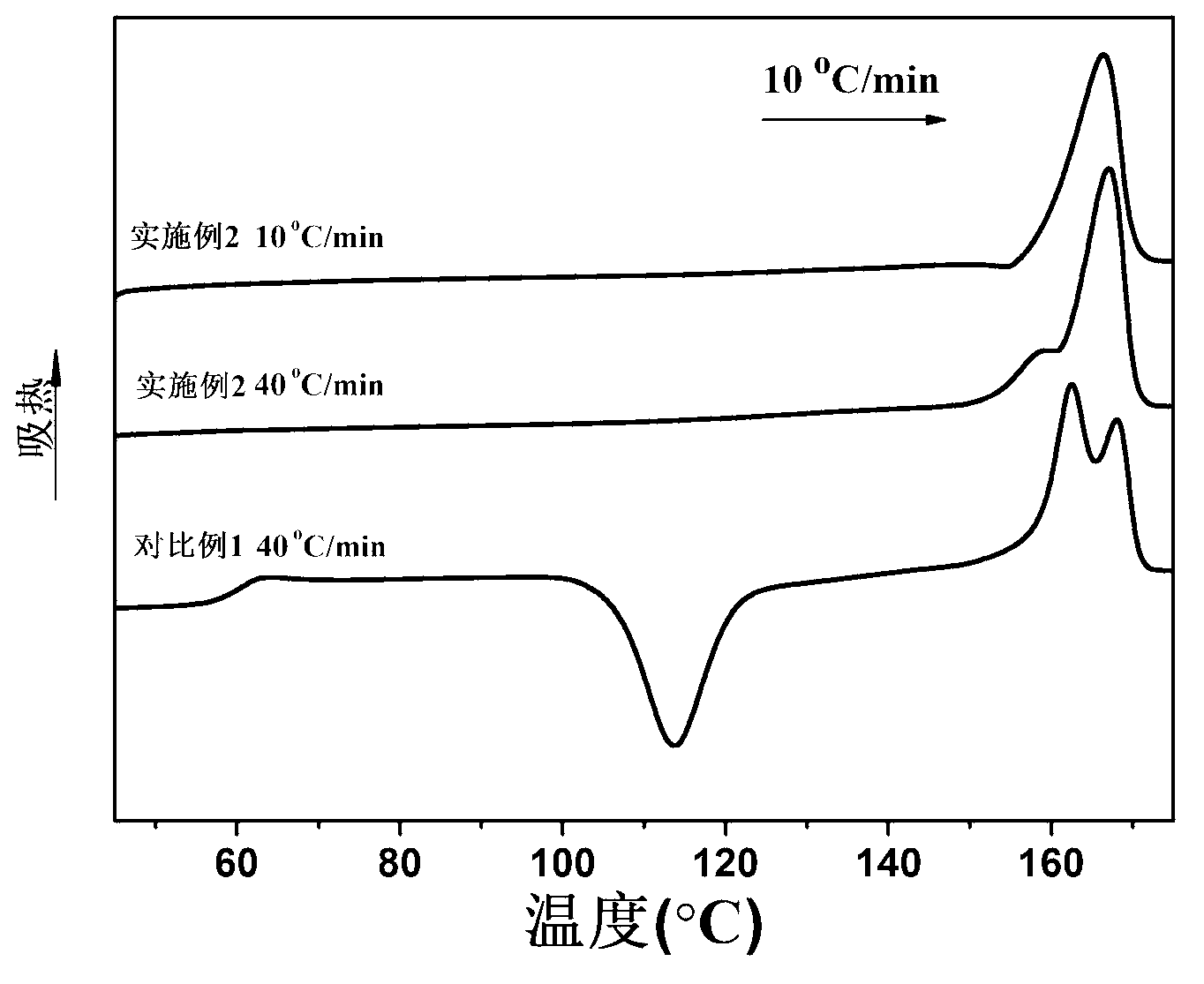

Embodiment 2

[0033] (1) Add 10g of poly-L-lactic acid to 100ml of dichloromethane solution at room temperature, stir for 3h; stand for later use; add 0.1g of poly-D-lactic acid to 10ml of dichloromethane solution, stir for 3h; stand for later use; Add 1g of polyethylene glycol to 10ml of dichloromethane solution, stir for 3h; let it stand for later use;

[0034] (2) Add all the poly(D-lactic acid dichloromethane solution) and the polyethylene glycol dichloromethane solution prepared in step (1) into the poly(L-lactic acid dichloromethane solution), and stir for 3 hours;

[0035] (3) The solution prepared in step (2) was left to stand at room temperature for 48 hours, and the solvent was evaporated to remove;

[0036] (4) The product obtained in step (3) was vacuum-dried at 50° C. for 48 hours to obtain a poly-L-lactic acid / poly-d-lactic acid / polyethylene glycol composite material sample with a ratio of (100 / 1 / 10).

Embodiment 3

[0038] (1) Add 10g of poly-L-lactic acid to 100ml of dichloromethane solution at room temperature, stir for 3h; stand for later use; add 0.1g of poly-D-lactic acid to 10ml of dichloromethane solution, stir for 3h; stand for later use; Add 2g of polyethylene glycol to 10ml of dichloromethane solution, stir for 3h; let it stand for later use;

[0039] (2) Add all the poly(D-lactic acid dichloromethane solution) and the polyethylene glycol dichloromethane solution prepared in step (1) into the poly(L-lactic acid dichloromethane solution), and stir for 3 hours;

[0040] (3) The solution prepared in step (2) was left to stand at room temperature for 48 hours, and the solvent was evaporated to remove;

[0041] (4) The product obtained in step (3) was vacuum-dried at 50° C. for 48 hours to obtain a poly-L-lactic acid / poly-d-lactic acid / polyethylene glycol composite material sample with a ratio of (100 / 1 / 20).

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com