Composite resin material capable of resisting high and low temperatures and high-energy radiation environment, and preparation method thereof

A resin composite material, radiation environment technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of poor condensation performance, lack of comprehensive performance, poor comprehensive performance, etc. The effect of excellent low temperature performance, light weight and excellent radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following non-limiting examples illustrate the invention.

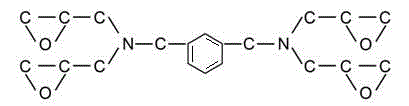

[0031] 1. A resin composite material resistant to high and low temperature and high-energy radiation environments, including a base layer and a composite layer closely combined with the base layer. It consists of dimethylamine tetraglycidylamine epoxy resin and reinforced resin with m-xylylenediamine tetraglycidylamine epoxy resin as the matrix material of the outer layer. As the above-mentioned preference, the reinforcing resin is reinforced m-xylylenediamine tetraglycidylamine epoxy resin with polyaramid fibers, and its specific components and weight percentages are:

[0032] 90% m-xylylenediamine tetraglycidylamine epoxy resin, 3% silicon powder, and 7% polyaramid resin.

[0033] 2, the preparation method of above-mentioned resin composite material, comprises the following steps successively:

[0034] 1) Apply m-xylylenediamine tetraglycidylamine epoxy resin on the aforementioned base layer by roller c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com