Lathe type roughing feed finish-machining adjustable cutter comprehensive tool system with finishing edge

A wiper and lathe technology, applied in the field of machining, can solve the problems of insufficient functionality, limited adjustment range of the adjustable tool system, poor stability, etc., to achieve the effect of wide application range, convenient adjustment of blade position, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

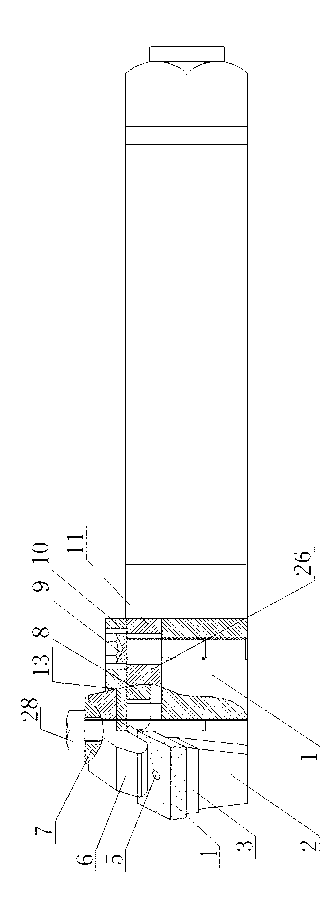

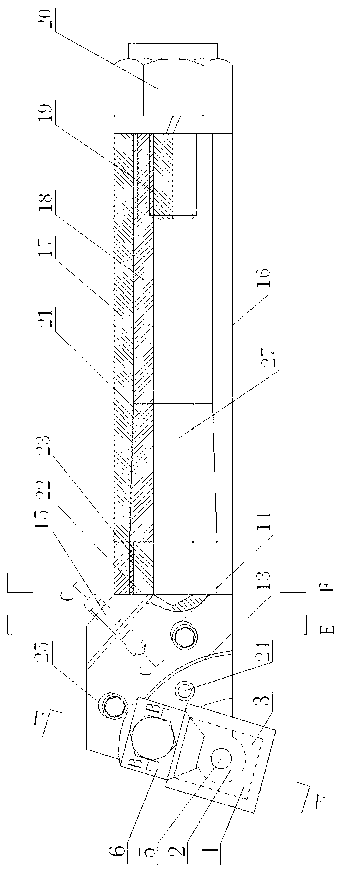

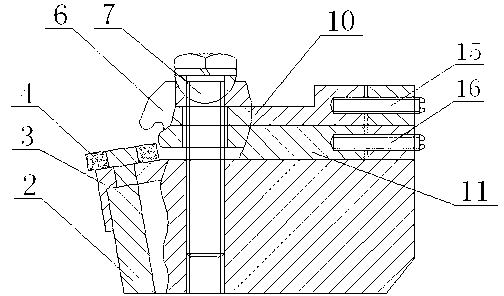

[0037] Such as figure 1 and 2 The comprehensive tool system for high-feed finishing adjustable tools with wiper blades on lathes shown includes a tool head subsystem, a tool bar subsystem, a clamping subsystem, and a tool pad subsystem. The main body of the tool head subsystem is the tool head 1, An arc-shaped adjustment surface 12 is provided on the lower end surface of the cutter head 1, and an arc-shaped cutter table 2, an upper pressing plate 6 and a lower pressing plate 8 are arranged on the cutting head 1, and the upper pressing plate 6 and the lower pressing plate 8 pass through the pressure pad 7 and the cutting head 1. Connection; one end of the upper platen 6 and the lower platen 8 is respectively connected to the upper baffle plate 10 and the lower baffle plate 11 to form a vector adjustment ramp 26, and the vector adjustment ramp 26 is fixedly connected to the cutter head 1 through the adjustable positioning hole 24 to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com