Method for improving rolling stability of high-strength IF steel

A stable and high-strength technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of F5 stand roll strain, large thickness fluctuation, strip thickness fluctuation, etc., to solve the problem of rolling The bottleneck problem of deviation, the reduction of roll strain accidents, and the effect of reducing the deviation rate of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: When producing high-strength IF steel, grade HC250IF, the raw material thickness is 2.8mm, the finished product thickness is 0.8mm, and when the finished product width is 1500mm, adjust its rolling reduction distribution as shown in Table 1:

[0019] Table 1

[0020] frame

F1 frame

F2 rack

F3 rack

F4 rack

F5 rack

Absolute reduction rate%

38.1

30.2

20.5

10.4

0.8

[0021] F1~F3 use work rolls with a crown of 50-75um, and the roughness of F1 work rolls is controlled to 1.0-1.2Ra / um.

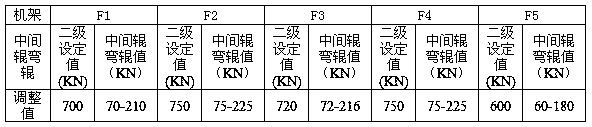

[0022] The roll shifting of the intermediate roll is set to 105% of the secondary set value, as shown in Table 2:

[0023] Table 2

[0024]

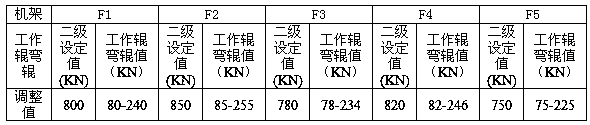

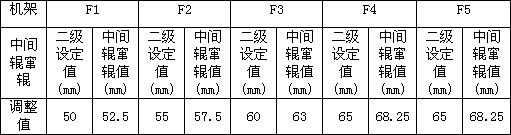

[0025] The roll bending value of the work roll and the intermediate roll is controlled at 10% to 30% of the set value of the second level, and rolling is carried out with a small bending force, as shown in Table 3 and Table 4:

[0026] table 3

[0027]

[0028] Table 4

[0...

Embodiment 2

[0031] Embodiment 2: when producing high-strength IF steel, grade HC250IF, raw material thickness is 3.3mm, finished product thickness is 1.2mm, and when finished product width is 1500mm, adjust its rolling reduction distribution as shown in table 5:

[0032] table 5

[0033] frame

F1 frame

F2 rack

F3 rack

F4 rack

F5 rack

Absolute reduction rate%

37.3

31.5

18.9

11.3

1.0

[0034] F1~F3 use work rolls with a crown of 50-75um, and the roughness of F1 work rolls is controlled to 1.0-1.2Ra / um.

[0035] The roll shifting of the intermediate roll is set to 105% of the secondary set value, as shown in Table 6:

[0036] Table 6

[0037]

[0038] The roll bending value of the work roll and intermediate roll is controlled at 10% to 30% of the secondary set value, and rolling is carried out with a small bending force, as shown in Table 7 and Table 8:

[0039] Table 7

[0040]

[0041] Table 8

[0042]

[0043] By adjust...

Embodiment 3

[0044] Embodiment 3: when producing high-strength IF steel, grade HC250IF, raw material thickness is 4.3mm, finished product thickness is 1.4mm, and when finished product width is 1500mm, adjust its rolling reduction distribution as shown in Table 9:

[0045] Table 9

[0046] frame

F1 frame

F2 rack

F3 rack

F4 rack

F5 rack

Absolute reduction rate%

36.2

29.8

18.4

14.4

1.2

[0047] F1~F3 use work rolls with a crown of 50-75um, and the roughness of F1 work rolls is controlled to 1.0-1.2Ra / um.

[0048] The roll shifting of the intermediate roll is set to 105% of the secondary set value, as shown in Table 10:

[0049] Table 10

[0050]

[0051] The roll bending value of the work roll and the intermediate roll is controlled at 10% to 30% of the set value of the second level, and rolling is carried out with a small bending force, as shown in Table 11 and Table 12:

[0052] Table 11

[0053]

[0054] Table 12

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com