Fume gas denitration system of coal-fired boiler based on SNCR (Selective Non-catalytic Reduction) and SCR (Selective Catalytic Reduction) combination method

A coal-fired boiler and combined method technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficulty in meeting flue gas emission requirements, low economizer outlet temperature, and high operating costs, and achieve denitrification. Reduced pressure, reduced difficulty and investment costs, reduced effect of ammonia slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

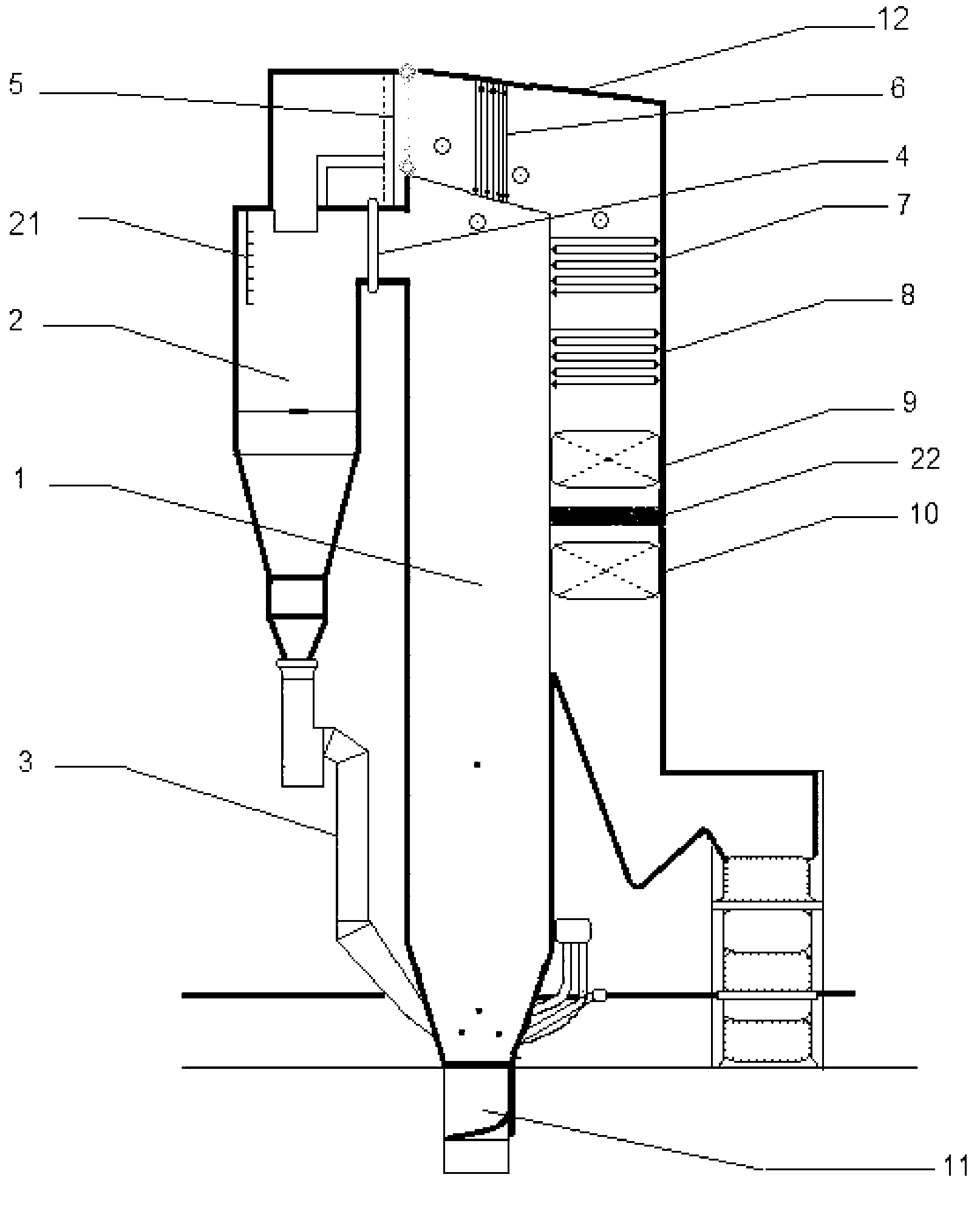

[0033] A coal-fired boiler SNCR and SCR combined flue gas denitrification system, including a boiler and an SCR denitrification device;

[0034] The boiler comprises a furnace 1, a flue gas outlet 4 of the furnace, a cyclone separator 2, a feeding device 3 and a tail flue 12;

[0035] The flue gas outlet 4 of the furnace is connected to the inlet of the cyclone separator 2, and the lower outlet of the cyclone separator 2 is connected to the dense phase area of the furnace through the feeding device 3;

[0036] At least one SNCR reducing agent injection device 21 is provided at the entrance 2 of the cyclone separator, the flue gas outlet 4 of the furnace or the upper part of the cyclone separator 2;

[0037] The SCR denitration device also includes an SCR denitration catalyst layer 22 .

[0038]A first-level economizer 9 and a second-level economizer 10 are arranged in the tail flue, and the SCR denitrification device is installed between the first-level economizer 9 and the...

Embodiment 2

[0047] Coal-fired boiler SNCR and SCR combined flue gas denitrification system, including boiler and SCR denitrification device;

[0048] The boiler includes a furnace 1. After the pulverized coal is burned in the furnace 1, the flue gas and incompletely burned solid particles enter the cyclone separator 2 through the flue gas outlet 4 of the furnace. The entrance of the cyclone separator 2 and the flue gas outlet 4 of the furnace Or at least one SNCR reducing agent injection device is provided on the upper part of the cyclone separator 2, and the SNCR reducing agent injection device is arranged on the flue gas channel with a temperature range of 800-1100°C.

[0049] Under the working condition of the flue gas temperature range of 800-1100°C, the injected reducing agent is rapidly thermally decomposed into NH 3 And it is strongly mixed with the high-temperature flue gas at the outlet of the boiler furnace at the position of the cyclone separator, and part of the NOx in the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com