Application of Chaenomeles speciosa (sweet) Nakai extract in pharmacy

A kind of papaya extract technology, applied in the field of papaya extract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

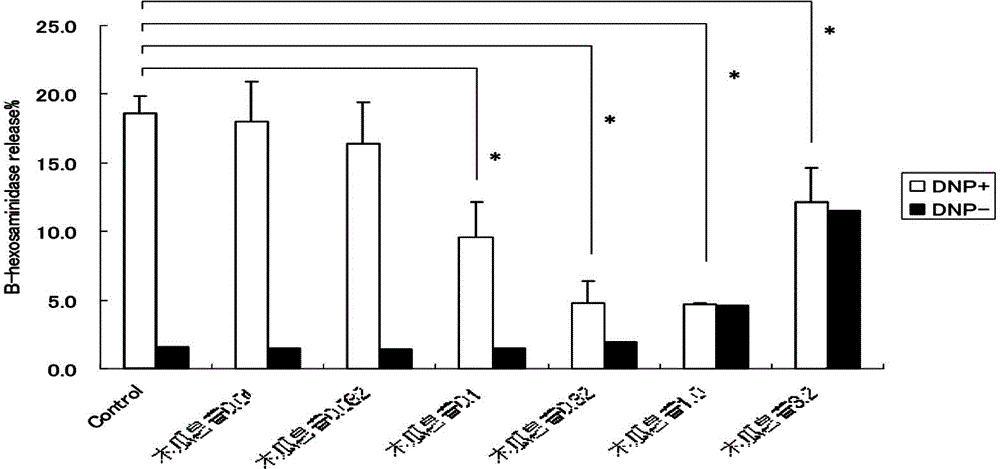

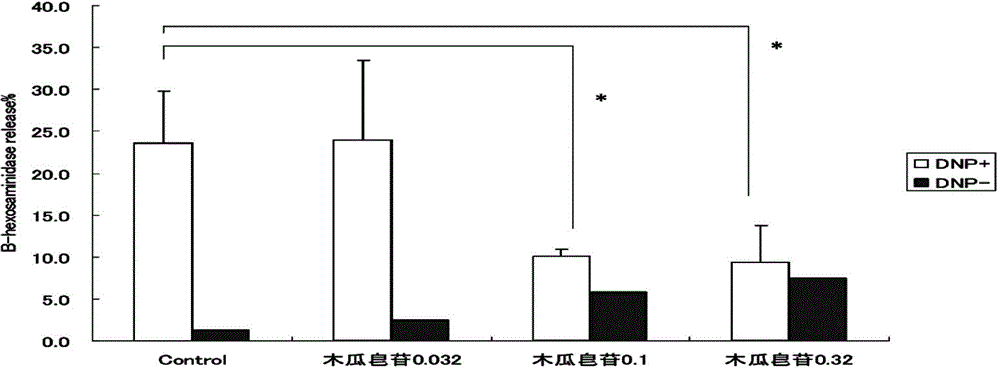

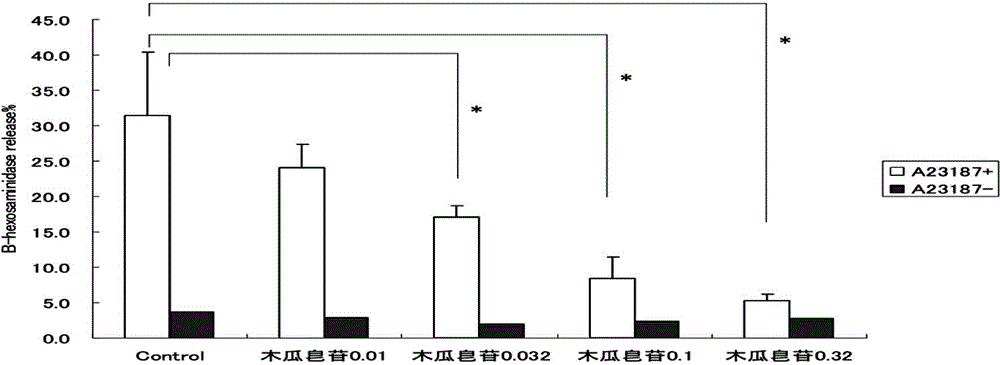

Image

Examples

Embodiment 1

[0039] Take 50kg of papaya decoction pieces, put them into the extraction tank, add 1.0% cellulase for enzymolysis, control the enzymolysis temperature at 58°C, and enzymolysis for 6 minutes; put the precipitate separated after enzymolysis into the extraction tank , add 500L of 50% ethanol to reflux and extract 3 times, each time for 2 hours, combine the extracts, recover the ethanol under reduced pressure until there is no alcohol smell, put it on a D-3520 macroporous adsorption resin column, and fully elute with water until the effluent is clear and After no reducing sugar reaction, elute with 60%, 70%, and 80% ethanol respectively, collect 60%, 70%, and 80% ethanol eluate, concentrate under reduced pressure and have no alcohol smell, filter, and add 10% hydrogen Sodium oxide solution adjusts the pH value to 9.0, adds 2 times the amount of water-saturated n-butanol to extract twice, combines the n-butanol solution, concentrates under reduced pressure to nearly dryness, and dr...

Embodiment 2

[0041] Take 50kg of papaya decoction pieces, put them into the extraction tank, add 1.0% cellulase for enzymolysis, control the enzymolysis temperature at 55°C, and enzymolysis for 10 minutes; put the precipitate separated after enzymolysis into the extraction tank , add 500L of 70% ethanol to extract 3 times, 2 hours each time, combine the extracts, recover the ethanol under reduced pressure until there is no alcohol smell, put it on the XAD-2 macroporous adsorption resin column, and fully elute with water until the effluent is clear and free of alcohol. After reducing sugar reaction, elute with 60%, 70%, 80% ethanol, collect 60%, 70%, 80% ethanol eluate, concentrate under reduced pressure without alcohol smell, filter, add 10% sodium hydroxide Adjust the pH value of the solution to 8.0, add 1 times the amount of water-saturated n-butanol to extract three times, combine the n-butanol liquid, concentrate under reduced pressure to nearly dryness, and dry under reduced pressure t...

Embodiment 3

[0043] Take 50kg of papaya decoction pieces, put them into the extraction tank, add 1.0% cellulase for enzymolysis, control the enzymolysis temperature at 52°C, and enzymolysis for 15 minutes; put the precipitate separated after enzymolysis into the extraction tank , add 500L 80% ethanol to reflux extraction 3 times, each time for 2 hours, combine the extracts, recover the ethanol under reduced pressure until there is no alcohol smell, put it on the XAD-4 macroporous adsorption resin column, and fully elute with water until the effluent is clear and free of alcohol. After reducing sugar reaction, elute with 60%, 70%, 80% ethanol, collect 60%, 70%, 80% ethanol eluate, concentrate under reduced pressure until no alcohol smell, filter, add 10% potassium hydroxide The pH of the solution is adjusted to be 9.0, add 2 times the amount of water-saturated n-butanol to extract twice, combine the n-butanol solution, concentrate under reduced pressure to nearly dryness, and dry under reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com