Cement admixture, cement composition, and hexavalent chromium reduction method using same

A technology of cement composition and mixed materials, which is applied in the field of concrete mixed materials to reduce hexavalent chromium, which can solve the problems of high reduction effect of hexavalent chromium and insufficient effect, and achieve high reduction effect of hexavalent chromium and reduction of hexavalent chromium Less decrease in effect and excellent initial strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

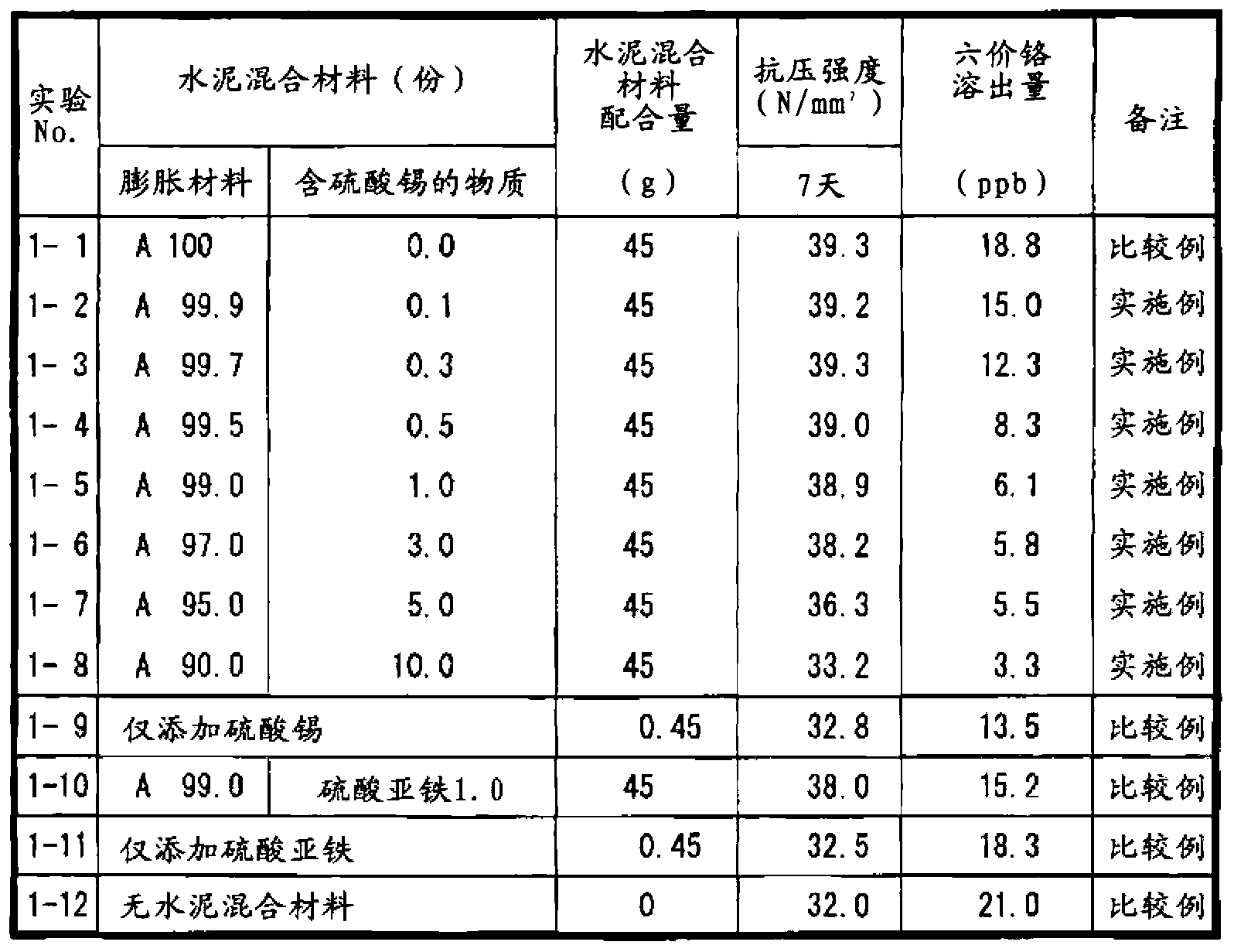

[0062] In 100 parts of the cement admixture containing the expansion material and the substance containing tin sulfate, the ratio of the expansion material and tin sulfate was changed as shown in Table 1, and the cement admixture was prepared.

[0063] Next, a standard mortar composed of 405 g of cement, 45 g of sewage sludge incineration ash, 225 g of water, and 1,350 g of sand was prepared.

[0064] Furthermore, the mortar which mix|blended the cement admixture in the amount shown in Table 1 by cement content ratio was manufactured in 20 degreeC environment. The mold was demoulded when the material was 1 day old, and after curing in water at 20° C. for 6 days, the compressive strength and the amount of elution of hexavalent chromium from the hardened product were evaluated.

[0065] Furthermore, as a comparative example, the case where tin sulfate was replaced with ferrous sulfate was also implemented. The results are shown in Table 1.

[0066]

[0067] Cement: Ordinary ...

Embodiment 2

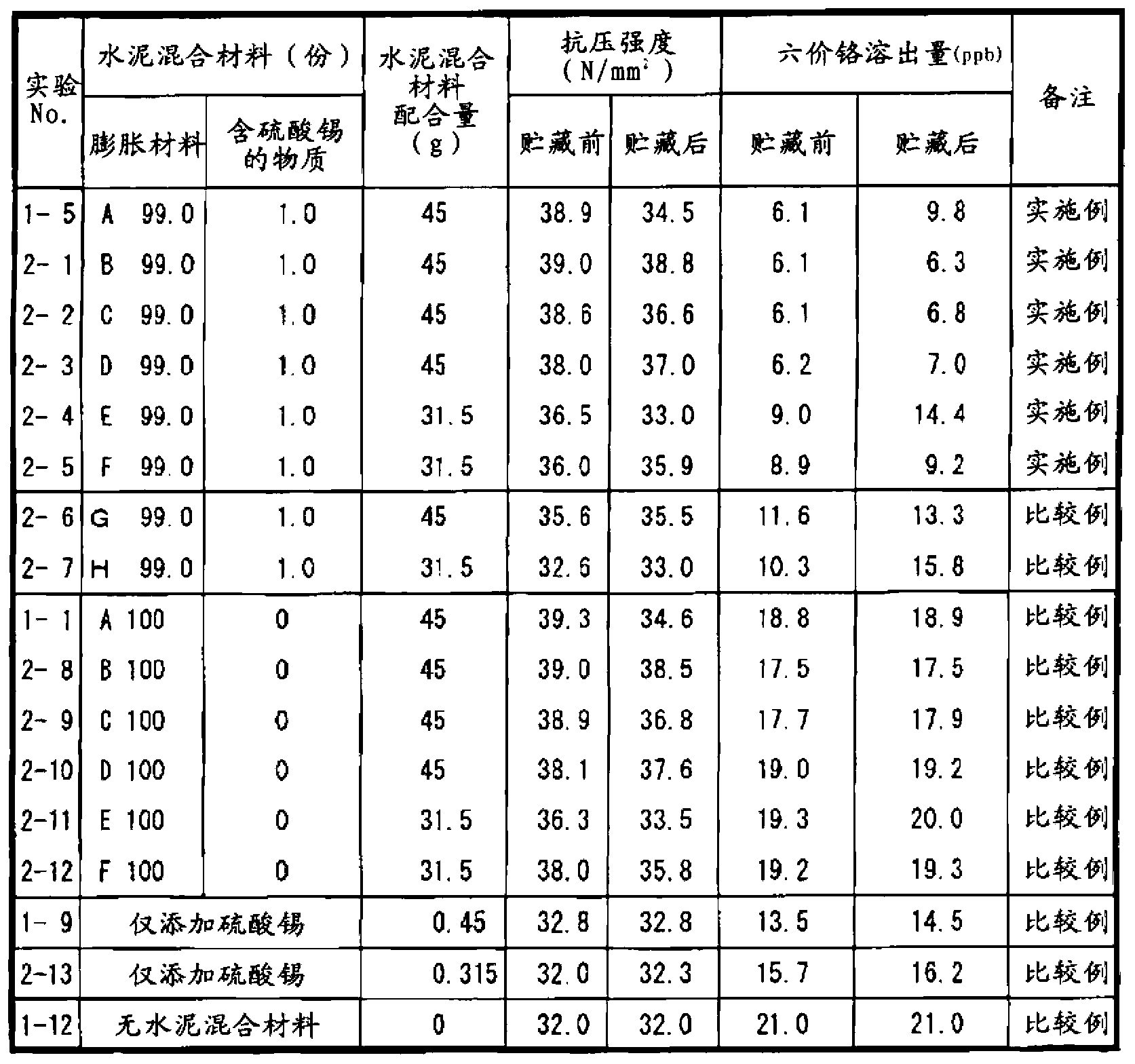

[0082] In 100 parts of the cement admixture containing the expansion material and the substance containing tin sulfate, the substance containing tin sulfate was fixed at 1.0 part, the type of the expansion material was changed, and the evaluation before and after the storage test of the cement admixture was performed, except It carried out similarly to Example 1. On the other hand, as a comparative example, no tin sulfate-containing substance was mixed, and each swelling material was evaluated independently. The results are shown in Table 2.

[0083]

[0084] Expansion material B: Place expansion material A in an alumina crucible, place it in an electric furnace, let 0.05L / min carbon dioxide gas flow relative to the inner volume of the electric furnace 1L, and react at a firing temperature of 600°C for 30 minutes at the same time. synthetic substances. 19 parts of free lime, 30 parts of blue square stone, 45 parts of anhydrous gypsum and 1 part of calcium carbonate, densit...

Embodiment 3

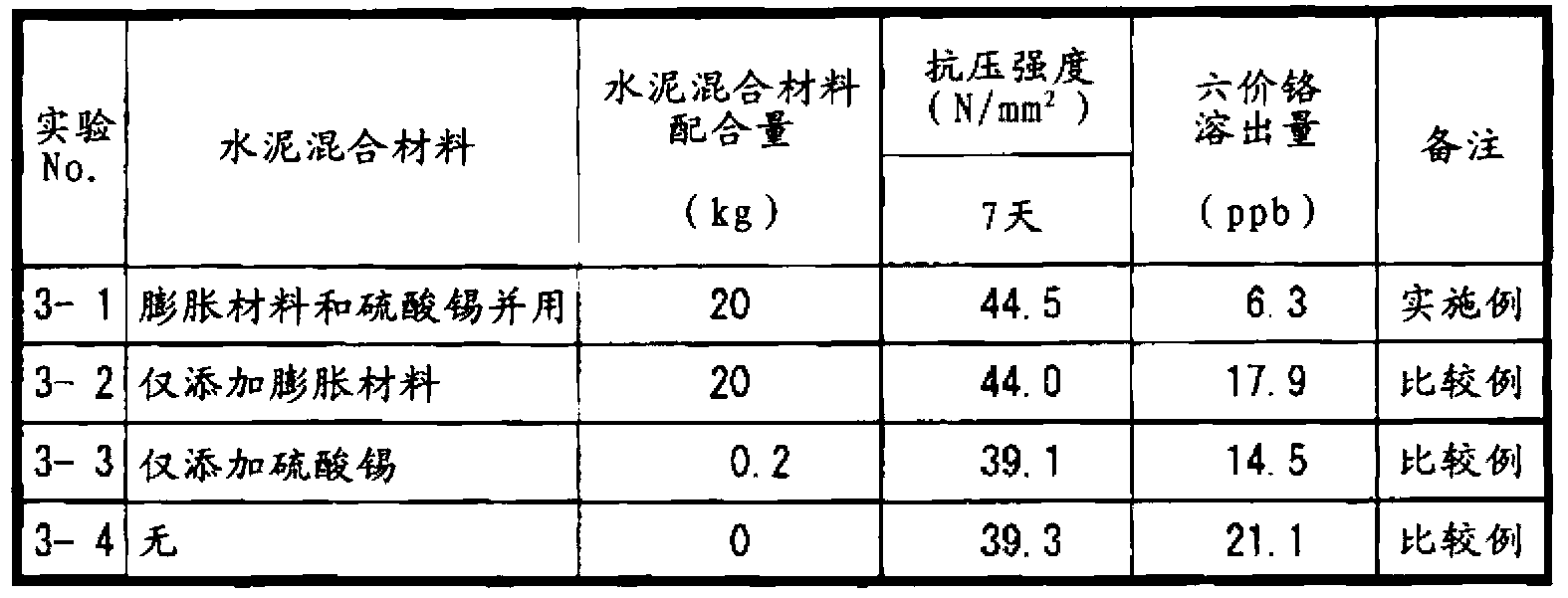

[0100] The compounding quantity of the tin sulfate-containing substance was fixed at 1.0 part in 100 parts of cement mixtures containing the expansion material A and the tin sulfate-containing substance, and the performance was evaluated with the concrete.

[0101] The concrete mix is set to 460kg of cement per unit, 48kg of incineration ash per unit of sewage sludge, 198kg of water per unit, 5.3kg of water reducing dosage per unit, S / a=55%, and 20kg of cement mixture based on the cement content ratio. The pouring of concrete is carried out at 20°C, after pre-curing at 20°C for 2 hours, at a heating rate of 20°C / hr, keep at the highest temperature of 60°C for 4 hours, and then cool naturally. After demoulding at a material age of 1 day, and curing in water at 20°C for 6 days, the compressive strength and hexavalent chromium dissolution test were carried out. The results are shown in Table 3.

[0102] In addition, for comparison, the case of adding only the expansion materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com