Method for reinforcing alkaline fermentation and acidogenesis of excess sludge by straws

A technology for excess sludge and straw, which is applied to chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of low acid production efficiency of anaerobic fermentation alone and low utilization rate of straw resources, and promotes The effects of acid production efficiency, sludge hydrolysis rate increase, and fermentation cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

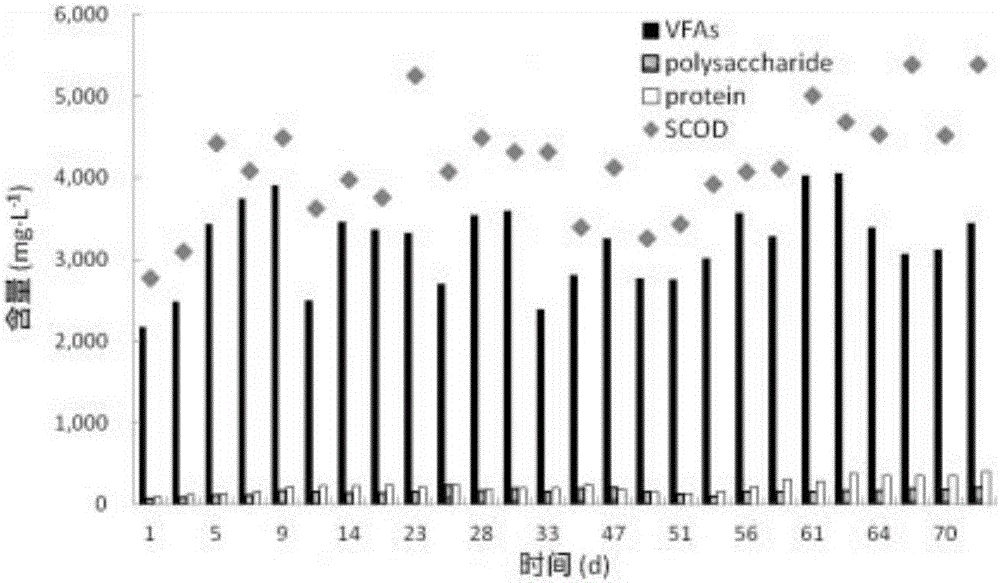

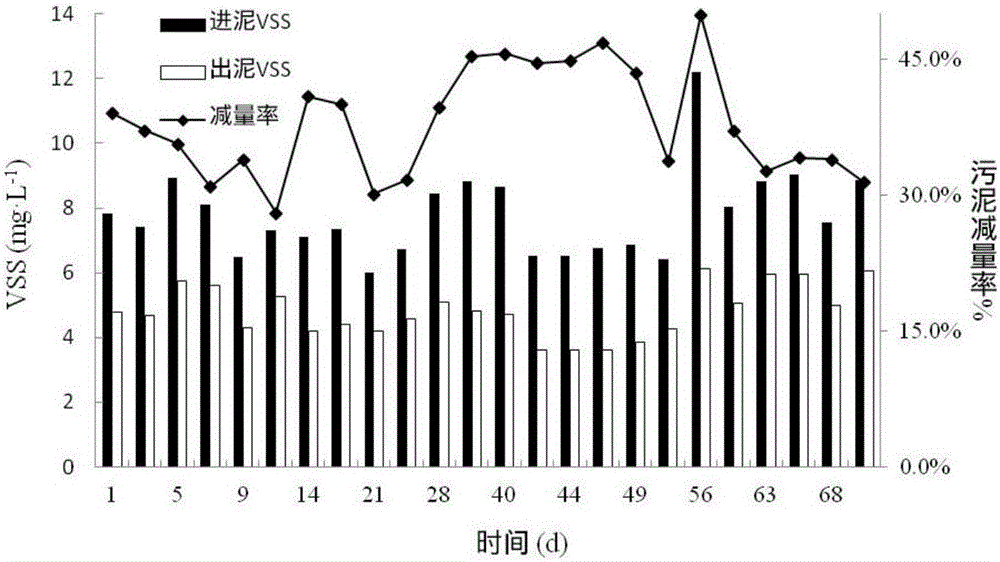

[0031] A method of using straw to strengthen the alkaline fermentation of residual sludge to produce acid. The method is carried out in a set of straw combined with sludge co-fermentation acid production system. Sequencing batch reactors are used for continuous anaerobic acid production. The daily sewage Mud treatment volume is 0.5m 3 / d, the specific steps are as follows:

[0032] 1. Pretreatment of straw

[0033] The straw comes from the rice straw in the farmland near the factory. The straw is naturally air-dried. The dried straw is cut into 5-7cm strips, washed with water, dried at 60°C to constant weight, and then crushed into powder by a pulverizer. Utilize alkali method to carry out chemical pretreatment to the stalk after pulverizing, and specific method is, be that the sodium hydroxide solution alkalization stalk of 3% with concentration, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com