Hardening agent for ready-mix shipped rapid-hardening concrete, ready-mix shipped rapid-hardening concrete material, ready-mix shipped rapid-hardening concrete composition, and method for preparing same

A technology of concrete composition and ready-mixed concrete, which is applied in the direction of mixing operation control, chemical instruments and methods, mixing operation control devices, etc., and can solve problems such as longer working hours, limited equipment, and increased cost of rapid-hardening concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

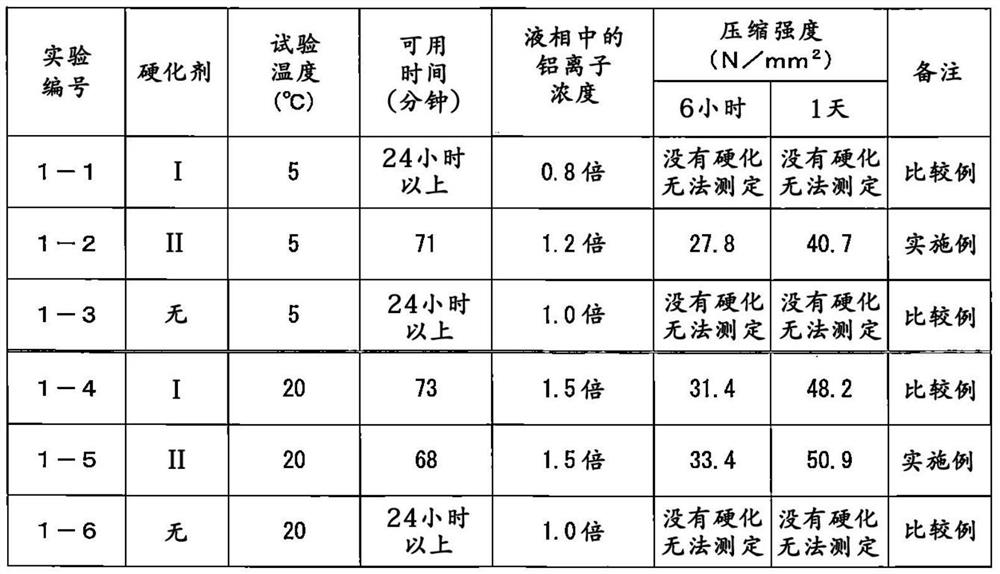

experiment example 1

[0114] Cement 380kg / m 3 , rapid hardening material 120kg / m 3 , water / bonding material ratio of 32%, s / a=42%, air volume of 2.0±1.5 volume% rapid hardening concrete is mixed in a mixing container for preparation. At this time, mix 1.5 parts of dormant agent with respect to 100 parts of cement and fast-hardening material, and set the volume after mixing to 85% of the internal volume of the mixing container so that it will not be hydrated for more than 24 hours. Hardened (material A). Assuming that the handling time before arriving at the site and the waiting time after arriving at the construction site were generated, 5 parts of various hardeners (material B) shown in the following Table 1 were added after 120 minutes with respect to 100 parts of bonding material (based on the expected value) Rapid hardening concrete composition shipped by mixing concrete). The pot life after the addition of the hardener was measured, and the compressive strength was measured 6 hours after th...

experiment example 2

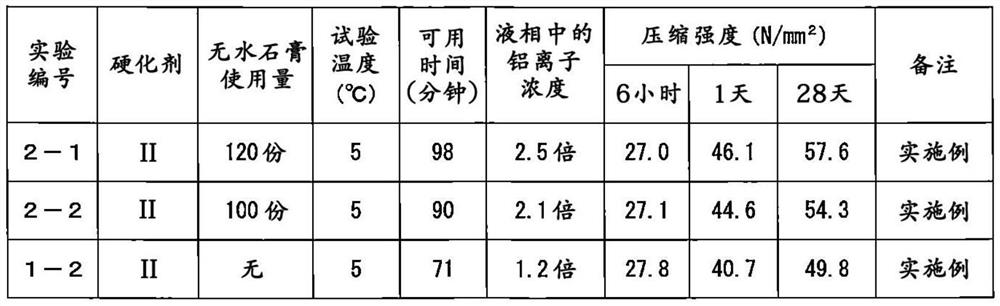

[0139] The curing agent II was used as the curing agent, and it was carried out in the same manner as in Experimental Example 1, except that anhydrite was blended as shown in the following table with respect to 100 parts of the curing agent II. The results are collectively described in Table 2 below.

[0140] Among them, anhydrous gypsum is based on the specific surface area of 5000cm 2 Type II natural anhydrous gypsum made in Thailand prepared by / g method.

[0141] [Table 2]

[0142]

[0143] From Table 2, it can be seen that by adding anhydrous gypsum to the curing agent, the expression of compressive strength after one day of material age becomes better.

experiment example 3

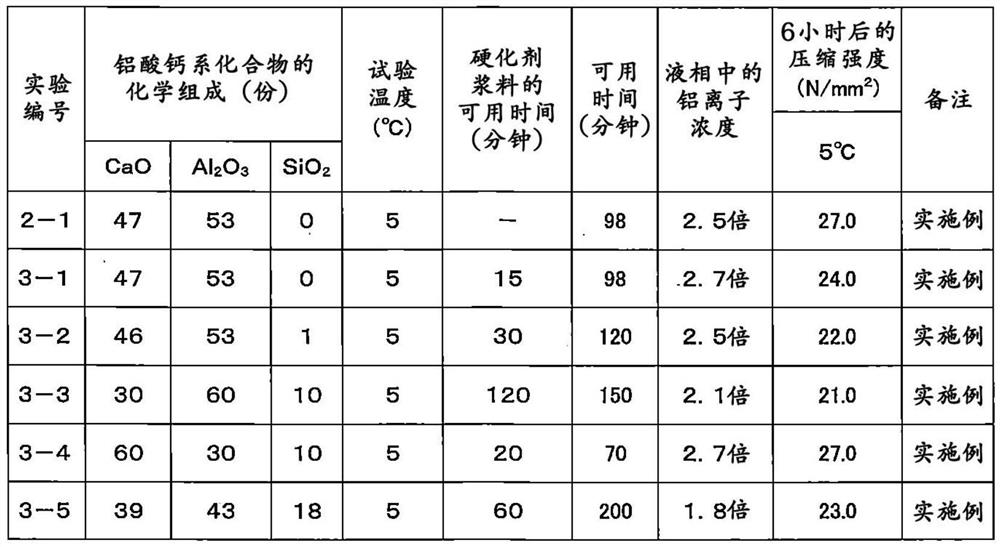

[0145] The chemical composition of the calcium aluminate compound of Hardener II is formulated as shown in the table below to prepare a slurry with a water / hardener ratio of 0.3 (1 part of dormant agent is added to 100 parts of Hardener II) The same procedure as in Experimental Example 2 was performed except that the curing agent II was used. The results are collectively described in Table 3 below.

[0146] In addition, the chemical composition was confirmed according to JIS R 5202 "Chemical Analysis Methods of Portland Cement".

[0147] [table 3]

[0148]

[0149] By appropriately changing the chemical composition of the calcium aluminate-based compound according to Table 3, the temperature-dependent improvement effect can be more fully exhibited, and rapid hardening can be suppressed when a curing agent is used in the slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com