Polypyrrole hollow microsphere/ sulfur composite material as well as preparation method and application thereof

A technology of hollow microspheres and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low sulfur utilization rate and low capacity, and achieve the effects of environmental friendliness, high capacity and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

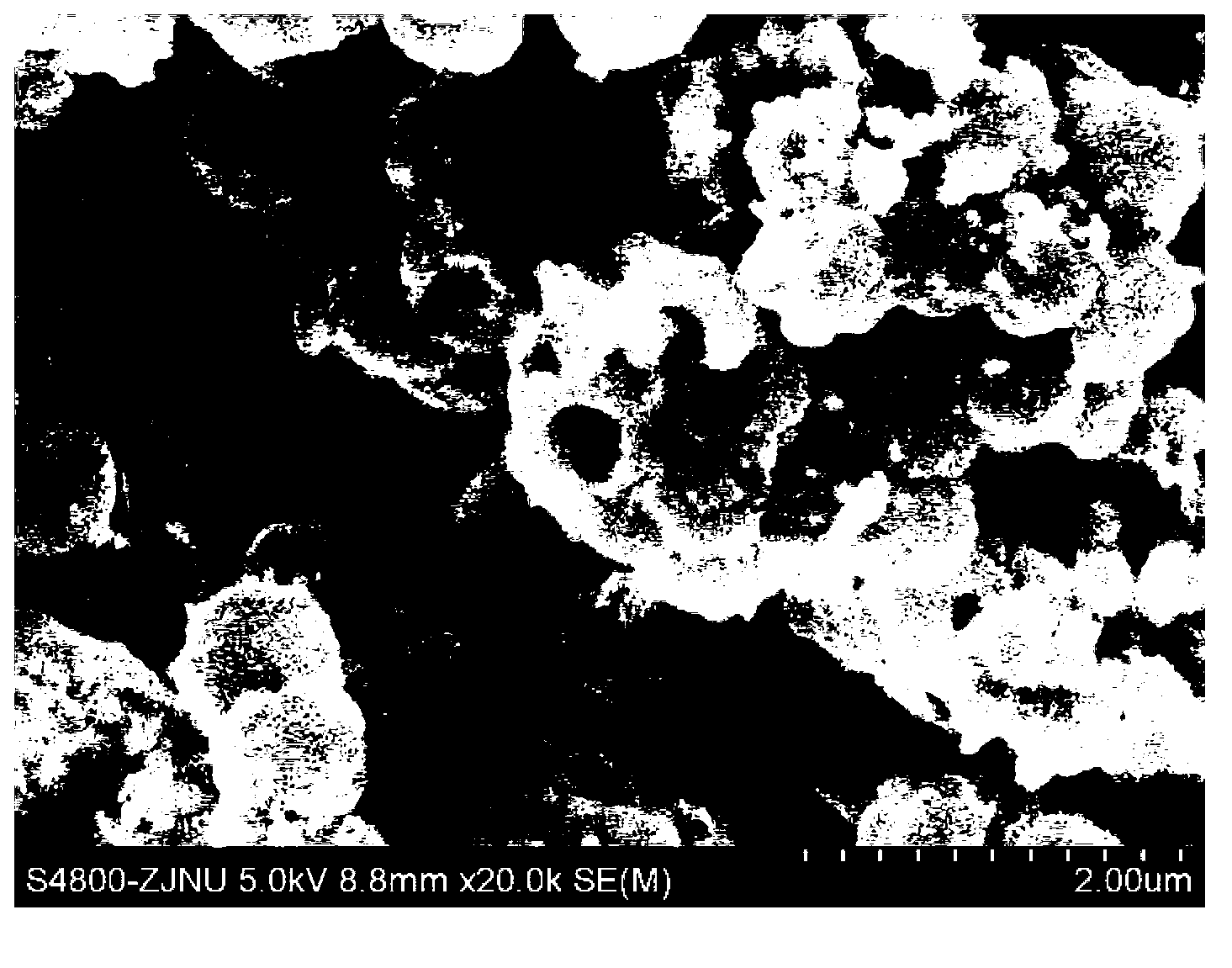

Image

Examples

Embodiment 1

[0034] A kind of step that prepares polypyrrole hollow microsphere / sulfur composite material with silicon dioxide microsphere, ferric chloride, pyrrole, hydrofluoric acid, water and sulfur powder as raw material is as follows:

[0035] (1) Weigh 0.9 g of silica microspheres and 1 mL of pyrrole respectively, mix with 150 mL of deionized water, and disperse by ultrasonic to form a suspension;

[0036] (2) Weigh 2.4 g of ferric chloride and dissolve it in 50 mL of deionized water to prepare ferric chloride solution;

[0037] (3) Add dropwise the ferric chloride solution prepared in step (2) to the suspension prepared in step (1), stir and react at room temperature for 24 hours to obtain a black precipitate;

[0038] (4) Dissolve 10mL of 40wt% hydrofluoric acid in 30mL of deionized water to prepare a 10wt% hydrofluoric acid solution;

[0039] (5) Wash the black precipitate prepared in step (3) with deionized water, dry it, mix it with the hydrofluoric acid prepared in step (4) an...

Embodiment 2

[0044] A kind of step that prepares polypyrrole hollow microsphere / sulfur composite material with silicon dioxide microsphere, ferric chloride, pyrrole, hydrofluoric acid, water and sulfur powder as raw material is as follows:

[0045] (1) Weigh 0.4 g of silica microspheres and 1 mL of pyrrole respectively, mix with 150 mL of deionized water, and disperse by ultrasonic to form a suspension;

[0046] (2) Weigh 2.4 g of ferric chloride and dissolve it in 50 mL of deionized water to prepare ferric chloride solution;

[0047] (3) Add dropwise the ferric chloride solution prepared in step (2) to the suspension prepared in step (1), stir and react for 30 h at room temperature to obtain a black precipitate;

[0048] (4) Dissolve 10mL of 40wt% hydrofluoric acid in 30mL of deionized water to prepare a 10wt% hydrofluoric acid solution;

[0049] (5) Wash the black precipitate prepared in step (3) with deionized water, dry it, mix it with the hydrofluoric acid prepared in step (4) and le...

Embodiment 3

[0052] A kind of step that prepares polypyrrole hollow microsphere / sulfur composite material with silicon dioxide microsphere, ferric chloride, pyrrole, hydrofluoric acid, water and sulfur powder as raw material is as follows:

[0053] (1) Weigh 0.9 g of silica microspheres and 1 mL of pyrrole respectively, mix with 150 mL of deionized water, and disperse by ultrasonic to form a suspension;

[0054] (2) Weigh 2.4 g of ferric chloride and dissolve it in 50 mL of deionized water to prepare ferric chloride solution;

[0055] (3) Add dropwise the ferric chloride solution prepared in step (2) to the suspension prepared in step (1), stir and react at room temperature for 12 hours to obtain a black precipitate;

[0056] (4) Dissolve 10mL of 40wt% hydrofluoric acid in 30mL of deionized water to prepare a 10wt% hydrofluoric acid solution;

[0057] (5) Wash the black precipitate prepared in step (3) with deionized water, dry it, mix it with the hydrofluoric acid prepared in step (4) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com