Preparation method for lithium-ion battery cathode material with high initial coulomb efficiency

A lithium-ion battery and negative electrode material technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of limiting the utilization rate of positive electrode materials, shedding, and low Coulombic efficiency, and achieve the effect of improving cycle capacity retention and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

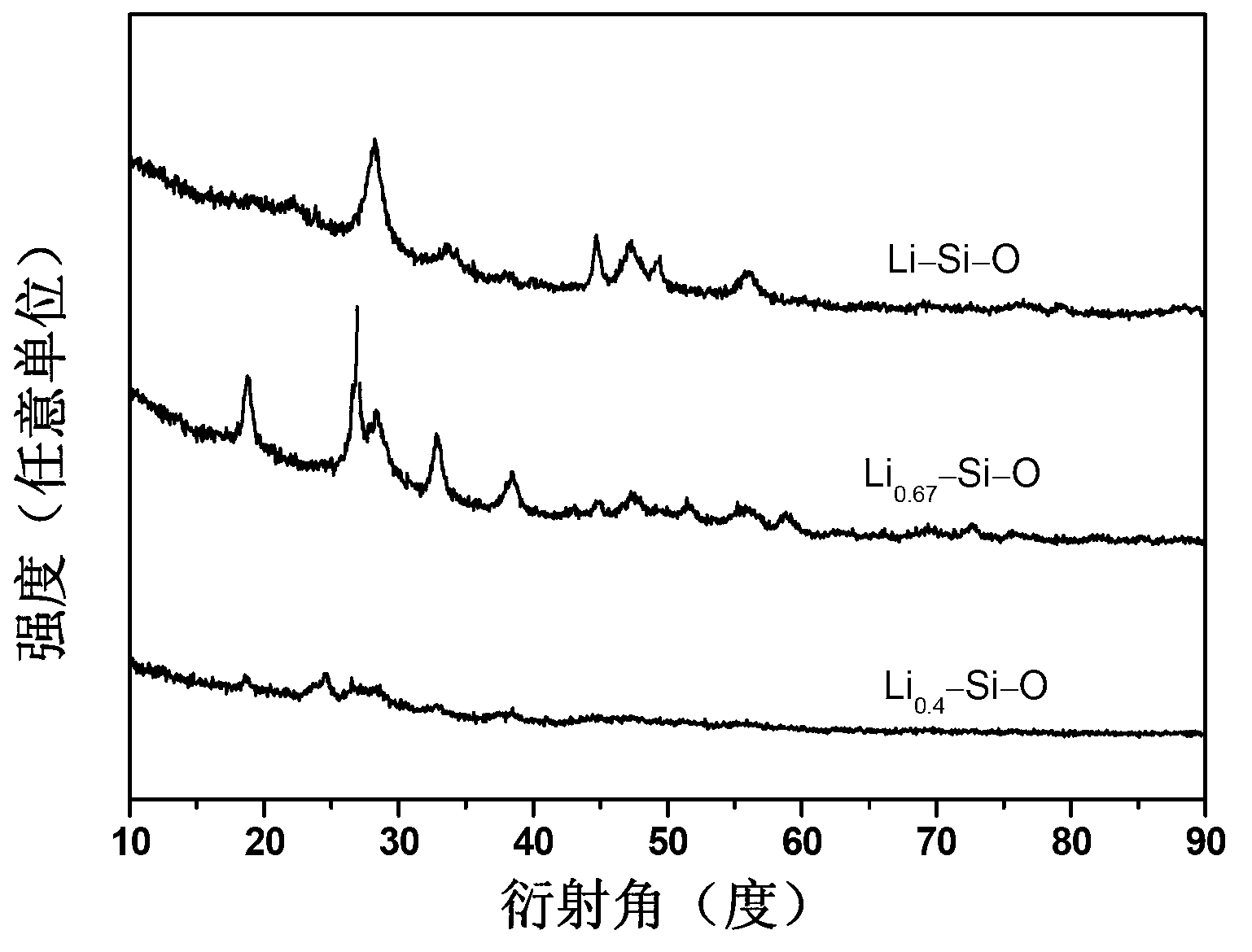

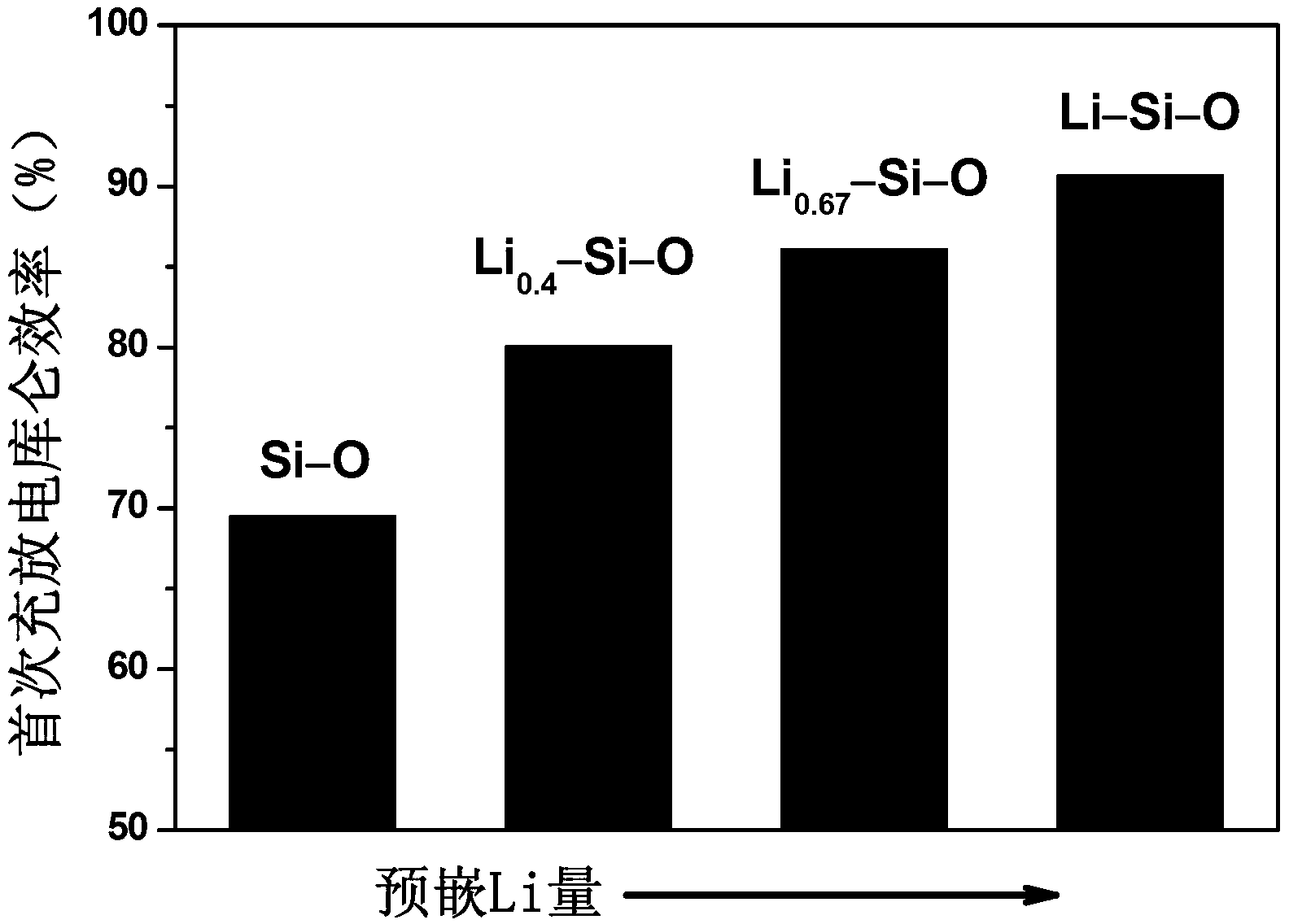

[0032] In a vacuum glove box, LiH and SiO were weighed and loaded into a ball mill jar at a molar ratio of 0.4:1, 0.67:1, and 1:1, respectively. The ball mill jar containing the mixture is placed on a planetary ball mill, and ball milled and mixed at a speed of 600 rpm for 1 hour, and the resulting mixed product is heated to 600 degrees Celsius at a heating rate of 10 degrees Celsius / minute under vacuum conditions, and kept for 12 hours Release hydrogen, vacuumize the system once every 0.5 hours during the heat preservation stage, and then cool down to room temperature to obtain Li-Si-O composites with different lithium contents. The obtained Li-Si-O composite was put into a ball mill jar with a ball-to-material ratio of 30:1, and then the ball mill jar was placed on a vibrating ball mill for 4 hours at a frequency of 1200 cycles / min to obtain a negative electrode material for a lithium-ion battery. figure 1 It is the X-ray diffraction spectrum of the obtained lithium ion batt...

Embodiment 4

[0035] In a glove box filled with argon, weigh LiH and SiO at a molar ratio of 1.2:1, put them into a ball mill jar with a ball-to-material ratio of 100:1, and place the ball mill jar containing the mixture on a horizontal planetary ball mill , ball milled at a speed of 200 rpm for 10 hours to obtain a mixture, and the resulting mixture was heated to 500 degrees Celsius at a heating rate of 5 degrees Celsius / minute under the protection of nitrogen flow, and kept for 36 hours to dehydrogenate, and the dehydrogenated product dropped to room temperature , get Li 1.2 -Si-O complex. The obtained product was put into a ball mill tank with a ball-to-material ratio of 60:1, placed on a planetary ball mill, and ball milled at a speed of 500 rpm for 8 hours to obtain the final product. The resulting final product was assembled into a simulated battery for electrochemical testing.

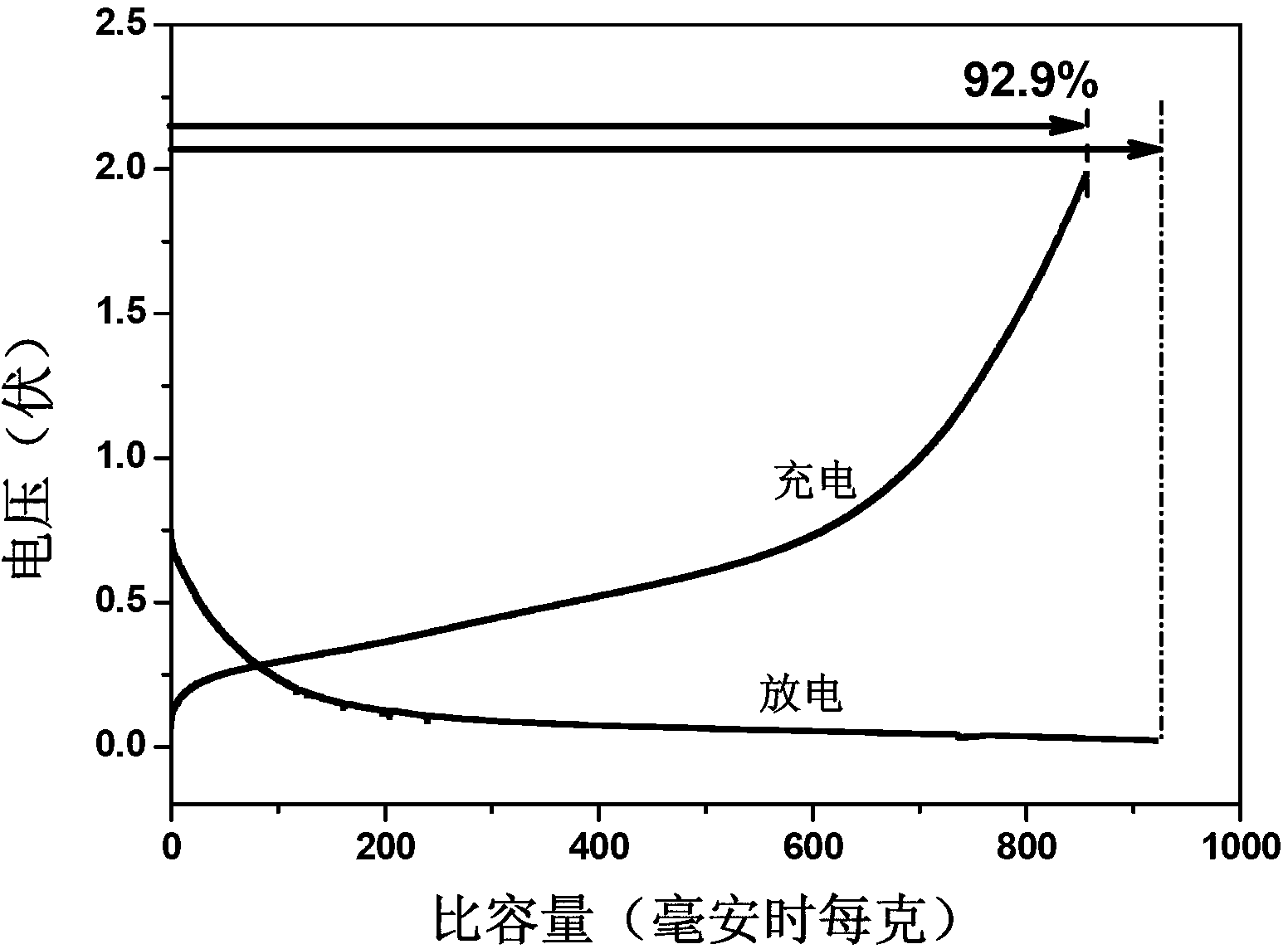

[0036] image 3 Shown is the first charge-discharge curve of the resulting final product. Depend on ...

Embodiment 5~8

[0038] In the glove box, weigh LiH and SiO into the ball milling jar according to the molar ratio of 0.1:1, 0.4:1, 0.75:1 and 1:1 respectively, and the ball-to-material ratio is 60:1. Placed on a vibrating ball mill, ball milled at a frequency of 1200 cycles / min for 2 hours, then heated the obtained mixture to 550 degrees Celsius at a heating rate of 12 degrees Celsius / minute under the protection of high-purity argon flow, and kept it warm for 24 hours to release hydrogen. The dehydrogenated product was cooled to room temperature, and finally the obtained dehydrogenated product was put into a ball mill tank with a ball-to-material ratio of 20:1, and ball milled on a horizontal planetary ball mill at a speed of 600 rpm for 36 hours to obtain the final product. The resulting final product was assembled into a simulated battery for electrochemical testing.

[0039] Figure 4 Shown is the cycle stability curve of the resulting final product. From Figure 4 It can be seen that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com