Pt nano flower micro needle type enzyme-free glucose sensor electrode and preparation method thereof

A glucose sensor and nanoflower technology, applied in the field of biosensors, can solve the problems of low binding force, low activity of inert electrodes, easy to fall off, etc., and achieve the effects of improved stability, favorable performance and good electrocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The silver alloy needle electrode was soaked in acetone, and ultrasonically cleaned to remove surface oil, then repeatedly cleaned with ethanol, ultrasonically, dried in the air, placed in a PBS solution with a pH value of 7.0, and activated by electrochemical cyclic voltammetry scanning for 10 lock up. Then it was placed in an electrolyte solution containing 0.5M sulfuric acid and 3mM chloroplatinic acid, using a three-electrode system, with a platinum electrode as an auxiliary electrode, a saturated calomel electrode as a reference electrode, and a pretreated silver alloy needle electrode as The working electrode was placed in an ultrasonic cleaning device, and the Pt nanoflower enzyme-free needle electrode was prepared by ultrasonic oscillation constant potential electrodeposition. The electrodeposition potential was -0.2V, the electrodeposition time was 600s, the electrodeposition temperature was 25°C, and ultrasonic The vibration power is 20W, and the interval time...

Embodiment 2

[0034] The operation process and experimental conditions of Example 2 are the same as those of Example 1, except that the ultrasonic intermittent oscillation electrodeposition potential is changed to -0.1V, and the electrodeposition time is 1000s.

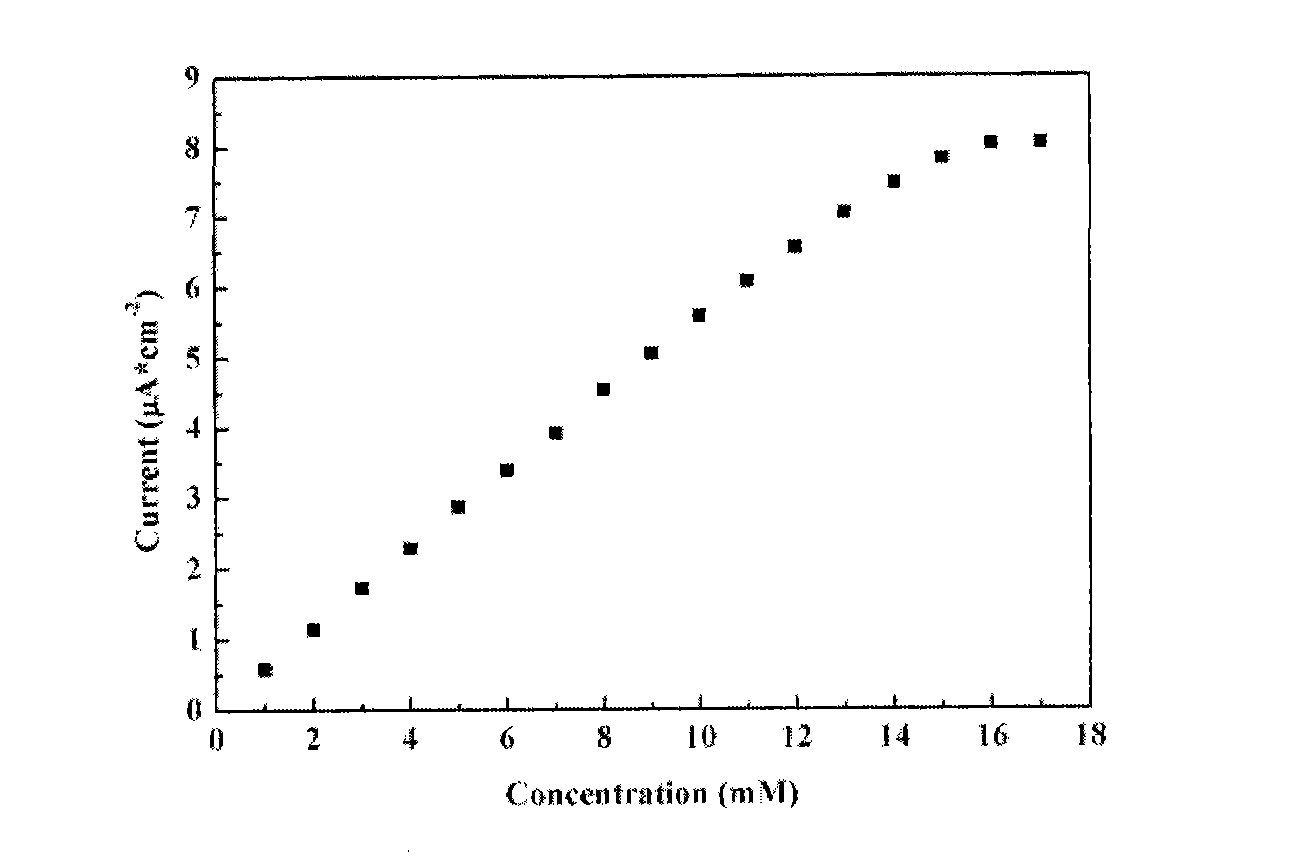

[0035] The prepared electrode was used as the working electrode, the Pt wire electrode was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. Into 30ml of blank PBS, 30μL of 1.5mol / L glucose solution was added dropwise successively, and after each dropwise addition, differential pulse voltammetry (DPV) measurement was carried out. figure 2 The results showed that the sensitivity of the prepared enzyme-free sensor was 1.87μA(cm -2 mM -1 ), the linear monitoring range is 1mM-16mM, and the detection limit is 48μM. After placing the electrode for three months, the response current is 92% of the initial response current. The sensor has very good stability, compared with the corres...

Embodiment 3

[0037] The operating process and experimental conditions of Example 3 are the same as in Example 1, except that the concentration of sulfuric acid is changed to 0.1M, and the concentration of chloroplatinic acid to 2mM.

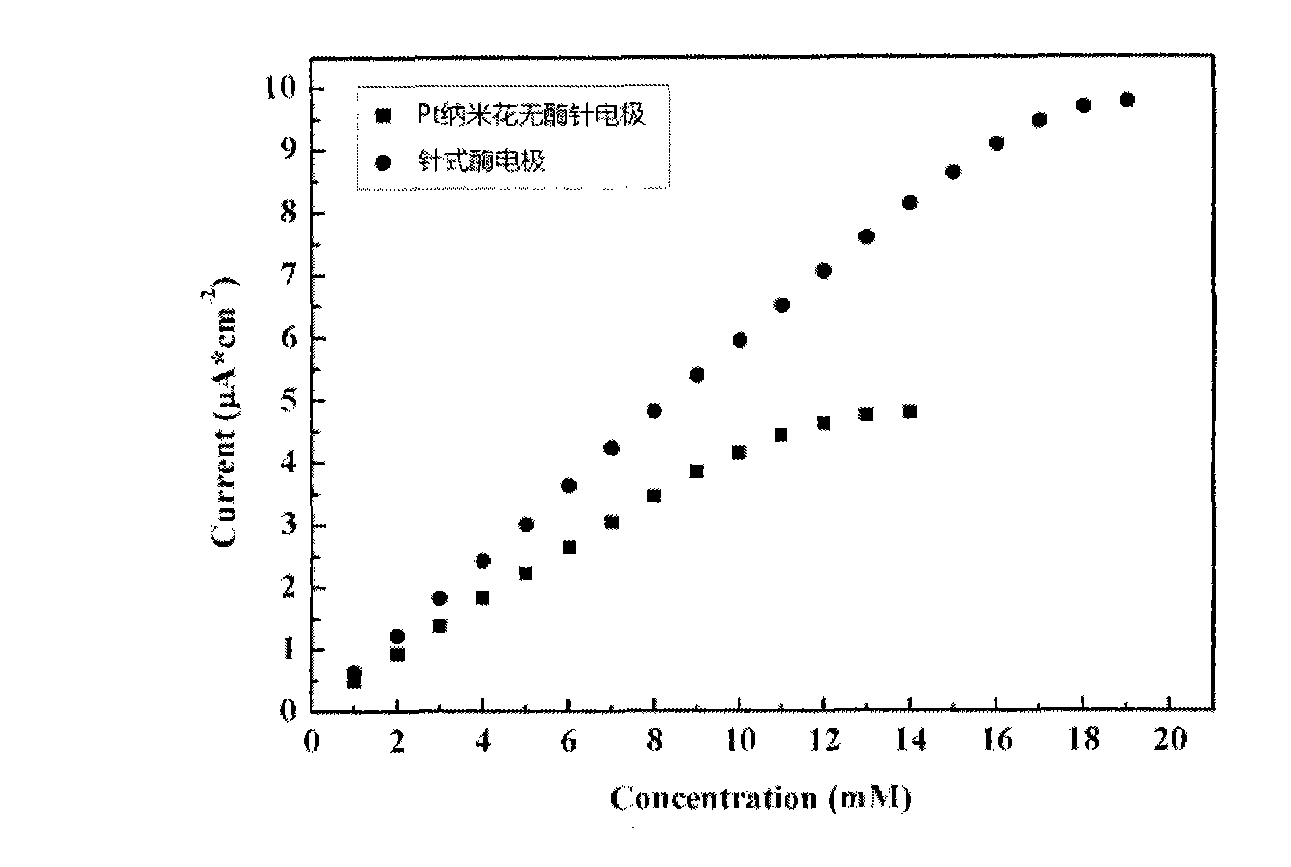

[0038] The prepared electrode was used as the working electrode, the Pt wire electrode was used as the auxiliary electrode, and the saturated calomel electrode was used as the reference electrode. Into 30ml of blank PBS, 30μL of 1.5mol / L glucose solution was added dropwise successively, and after each dropwise addition, differential pulse voltammetry (DPV) measurement was carried out. image 3 The results show that the sensitivity of the prepared sensor is 0.53μA*(cm -2 mM -1 ), the linear monitoring range is 1-15mM, and the detection limit is 169μM. After placing the electrode for three months, the response current is 91% of the initial response current. Compared with the corresponding pin-type enzyme sensor (performance see figure 1 ), wider linear range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com