Method for improving pad dyeing fixation rate of textile

A technology for textiles and color fixing rate, applied in the field of textile printing and dyeing, can solve the problems of expensive ionic liquid, shorten the dyeing time, and narrow the application range, and achieve the effects of improving the utilization rate, reducing the dosage of auxiliaries, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

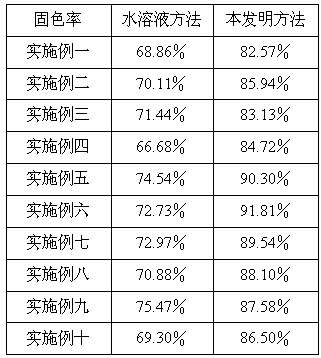

Examples

Embodiment 1

[0034] According to the above process steps: select 1g of cotton textiles as the textiles to be dyed. Place reactive dyes in a mixture of ethanol and water, stir evenly, and prepare a dye solution, wherein the bath ratio of the dye solution is 1:20, the volume ratio of ethanol and water is 95%:5%, and the concentration of reactive dyes 1% of the mass of cotton textiles. The cotton textiles are dipped twice in the second pad dyeing solution, and the cotton textiles have a liquid-carrying rate of 70%, and then the cotton textiles soaked in the pad dyeing solution are dried at a drying temperature of 80° C. and a drying time of 5 minutes. Sodium carbonate is placed in the mixed solution of ethanol and water, and after stirring evenly, it is prepared into a color-fixing solution, wherein the bath ratio of the color-fixing solution is 1:20, the volume ratio of ethanol and water is 95%:5%, and sodium carbonate The concentration is 5g / L. The cotton textiles that have been dipped in...

Embodiment 2

[0036] According to the above process steps: select 1g of cotton textiles as the textiles to be dyed. Put the reactive dye in the mixed solution of isopropanol and water, stir it evenly to prepare the dye solution, wherein the bath ratio of the dye solution is 1:50, the volume ratio of isopropanol and water is 50%:50%, the reactive dye The concentration is 5% of the mass of cotton textiles. The cotton textiles are dipped and padded with the dyeing solution one by one, and the liquid-carrying rate of the hemp textiles is 60%, and then the cotton textiles with the padding solution are dried at a drying temperature of 80°C and a drying time of 3 minutes. Sodium bicarbonate is placed in the mixed solution of isopropanol and water, and the color fixing solution is prepared after stirring evenly, wherein the bath ratio of the color fixing solution is 1:20, and the volume ratio of isopropanol and water is 50%:50% , the concentration of sodium bicarbonate is 10g / L. The cotton textil...

Embodiment 3

[0038]According to the above process steps: select 1g of hemp textiles as the textiles to be dyed. Place reactive dyes in a mixture of ethanol and water, stir evenly, and prepare a dye solution, wherein the bath ratio of the dye solution is 1:20, the volume ratio of ethanol and water is 95%:5%, and the concentration of reactive dyes It is 1% of the quality of hemp textiles. The hemp textiles are soaked in the second pad dyeing solution, and the liquid carrying rate of the hemp textiles is 70%, and then the hemp textiles dipped in the pad dyeing solution are dried at a drying temperature of 80 ° C and a drying time of 5 minutes. Sodium carbonate is placed in the mixed solution of ethanol and water, and after stirring evenly, it is prepared into a color-fixing solution, wherein the bath ratio of the color-fixing solution is 1:20, the volume ratio of ethanol and water is 95%:5%, and sodium carbonate The concentration is 5g / L. Dipping and second-rolling the color-fixing solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com