Ultra-high current density electrolysis or electrowinning cell

A technology of current density and electrowinning cell, which is applied in the field of ultra-high current density electrolysis or electrowinning cell, which can solve problems such as electrolytic cell leakage, damage to the anti-corrosion layer, and box damage, so as to achieve smooth production and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

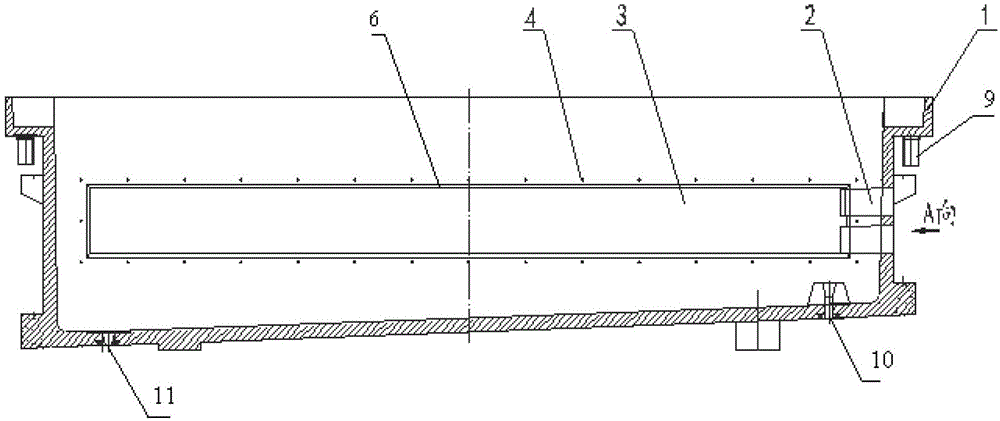

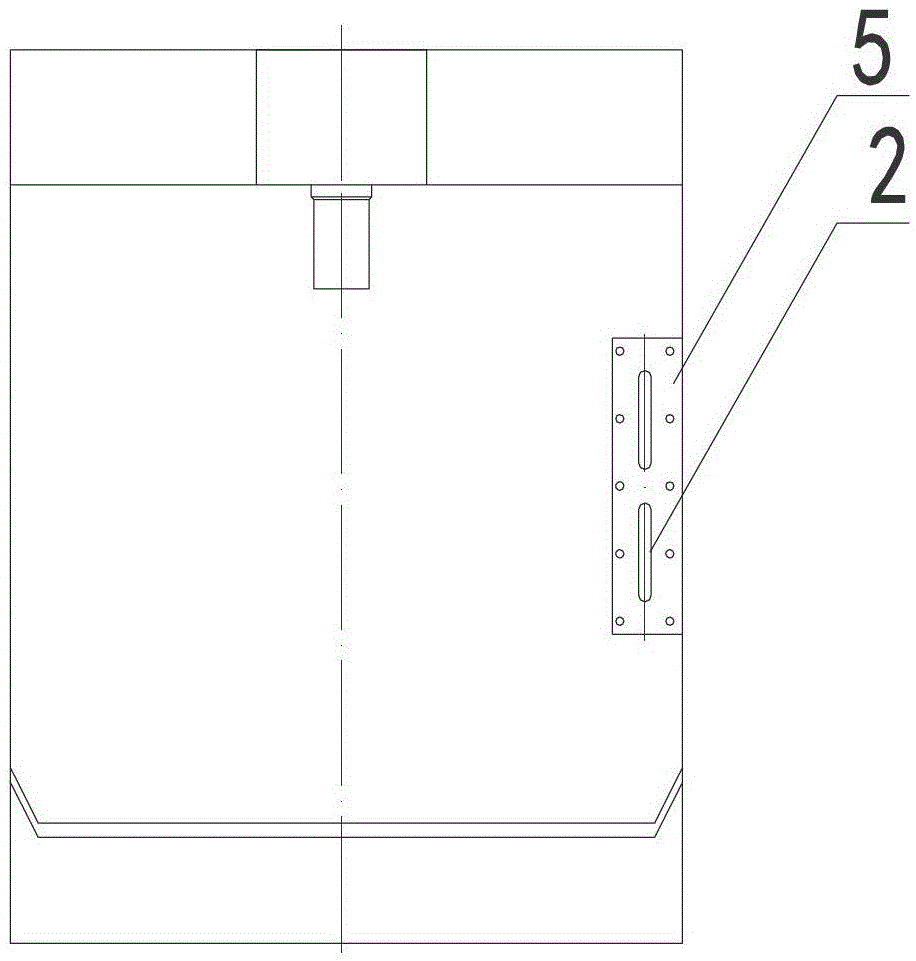

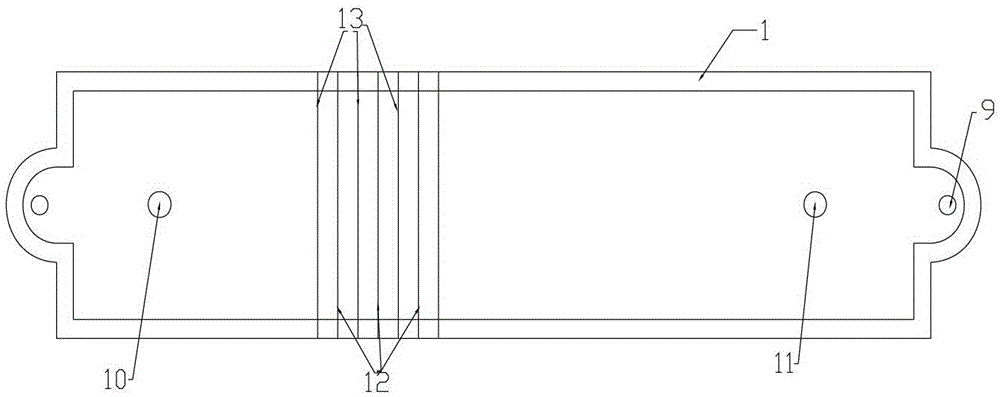

[0064] In the electrolytic cell, 54 rough copper anode plates 13 and 53 pure copper cathode plates 12 are placed at intervals, the mixed solution of sulfuric acid and copper sulfate is used as the electrolyte, and the external liquid supply system is connected to the liquid supply device through the flange 5 to supply After the electrolyte is energized, the supplied electrolyte enters the closed cavity 3 of the liquid supply device through the liquid inlet 2, and is evenly distributed along it, and passes through the electrolyte spraying device 8 on the panel 6 along the parallel and close to The direction of the cathode plate is ejected, and then the ejected electrolyte moves to both ends of the cell through the cavity between the electrode plate and the side wall of the cell, and the cavity between the electrode plate and the bottom of the cell, and finally flows from the two sides of the cell. The overflow port 9 at the end returns to the electrolyte circulation system.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com