Method for enhancing hot-rolled Gaussian texture of double-roller ribbon continuous casting oriented silicon steel

A technology of twin-roll strip continuous casting and oriented silicon steel, which is applied in metal rolling and other directions, can solve the problems of low strength of hot-rolled Goss texture and difficulty in manufacturing oriented silicon steel, and achieve enhanced hot-rolled Goss texture and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The chemical composition of grain-oriented silicon steel in the examples is shown in Table 1.

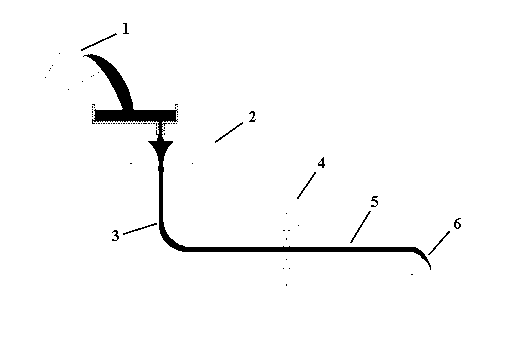

[0025] like figure 1 As shown, molten steel is smelted in an intermediate frequency vacuum induction furnace 1. The molten steel is passed through a twin-roll continuous casting machine 2 to form an oriented silicon steel thin strip 3 with a thickness of 3 mm. It is air-cooled to 1100° C. and is subjected to two passes of asynchronous hot rolling on a hot rolling mill 4. The speed ratio is 1.30, the total reduction ratio is 35%, and the hot-rolled sheet 5 is obtained. After the hot-rolled sheet is cooled to 600°C, it is coiled on the coiler 6 to obtain a hot-rolled sheet of oriented silicon steel with enhanced Goss texture.

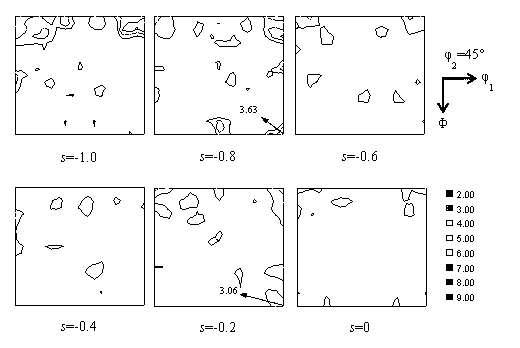

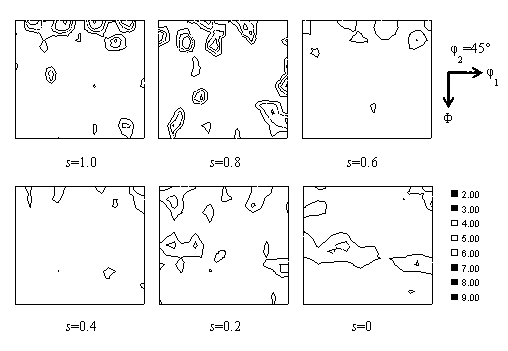

[0026] figure 2 is the texture distribution diagram of each thickness layer of the asynchronously hot-rolled grain-oriented silicon steel sheet near the fast roll, where the parameter s Indicates the measurement position of the texture, s= 2 a / d ,i...

Embodiment 2

[0030] The chemical composition of the grain-oriented silicon steel in the examples is shown in Table 2.

[0031] like figure 1 As shown, molten steel is smelted in an intermediate frequency vacuum induction furnace 1. The molten steel is passed through a twin-roll continuous casting machine 2 to form an oriented silicon steel thin strip 3 with a thickness of 10mm. It is air-cooled to 850°C and is subjected to 2 passes of asynchronous hot rolling on a hot rolling mill 4. The speed ratio is 1.10, the total reduction rate is 50%, and the hot-rolled sheet 5 is obtained. After the hot-rolled sheet is cooled to 500°C, it is coiled on the coiler 6 to obtain a hot-rolled sheet of oriented silicon steel with enhanced Goss texture.

[0032] After testing, the surface layer of the asynchronously hot-rolled grain-oriented silicon steel sheet in this example near the fast roll is stronger {001} The fiber texture, the central layer is a diffuse texture, and a strong Gaussian textur...

Embodiment 3

[0036] The chemical composition of grain-oriented silicon steel in the examples is shown in Table 3.

[0037] like figure 1 As shown, molten steel is smelted in an intermediate frequency vacuum induction furnace 1. The molten steel is passed through a twin-roll continuous casting machine 2 to form an oriented silicon steel thin strip 3 with a thickness of 1mm, and is air-cooled to 1200°C for one pass of asynchronous hot rolling on a hot rolling mill 4. The speed ratio is 1.50, the total reduction rate is 10%, and the hot-rolled sheet 5 is obtained. After the hot-rolled sheet is cooled to 700°C, it is coiled on the coiler 6 to obtain a hot-rolled sheet of oriented silicon steel with enhanced Goss texture.

[0038] After testing, the surface layer of the asynchronously hot-rolled grain-oriented silicon steel sheet in this example near the fast roll is stronger {001} The fiber texture, the central layer is a diffuse texture, and a strong Gaussian texture is observed.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com