Al-Mg-Zn-Cu alloy and preparation method thereof

An alloy and intermediate alloy technology, applied in the field of alloys, can solve the problems of affecting surface quality, strength and dent resistance, unable to meet the requirements of body panels, poor impact resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

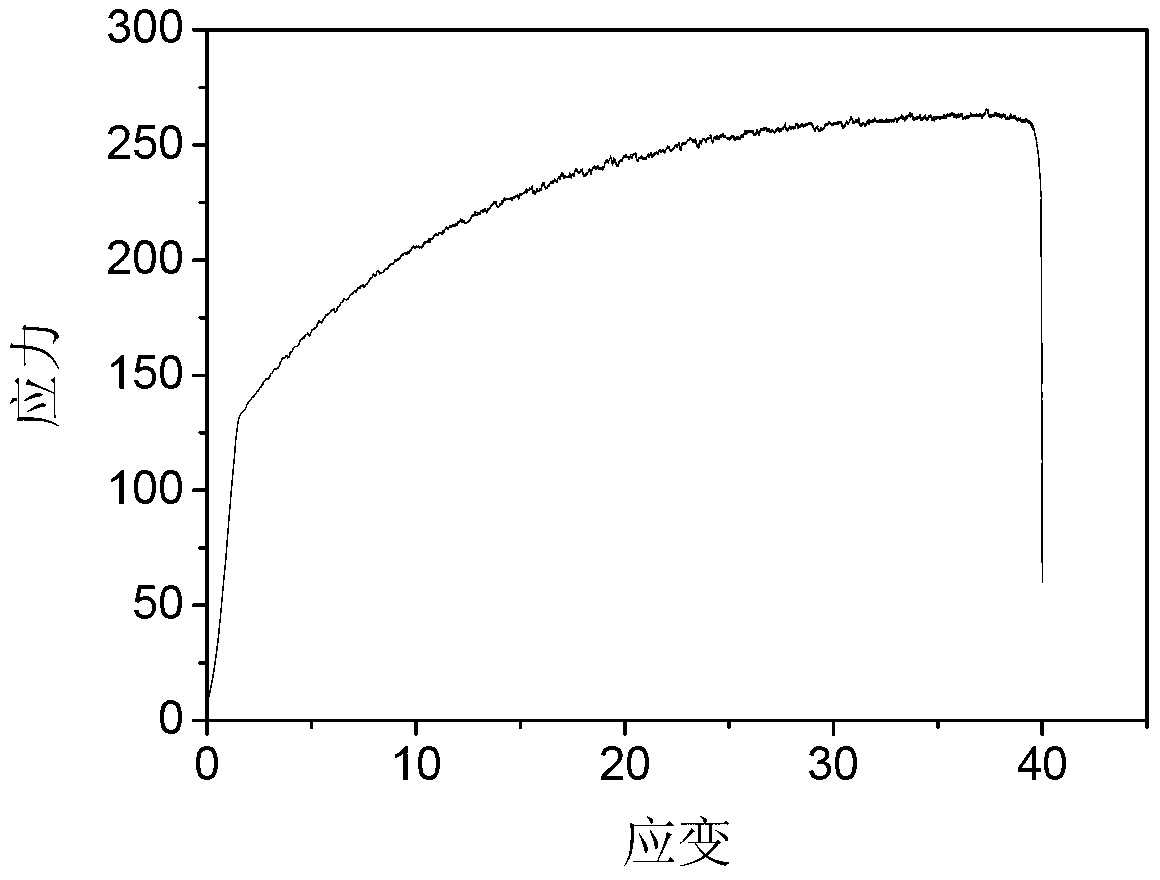

Image

Examples

preparation example Construction

[0062] The invention provides a kind of preparation method of Al-Mg-Zn-Cu alloy, comprises the following steps:

[0063] a) Melting and casting the components contained in the alloy described in the above technical solution to obtain an ingot;

[0064] b) performing homogenization treatment, hot rolling, annealing, cold rolling and solution quenching treatment on the ingot in sequence;

[0065] c) leveling the aluminum alloy plate after the solution quenching treatment in step b);

[0066] d) heat-treating the aluminum alloy plate after the leveling treatment in step c), and obtain an Al-Mg-Zn-Cu alloy plate for automobile body after cooling.

[0067] The present invention melts and casts the components described in the above technical solution to obtain an ingot. In the present invention, the process of melting and casting preferably includes the following steps:

[0068] After melting the aluminum ingot, add AlCu50, AlMn10 master alloy, Zn and covering agent when the melt ...

Embodiment 1

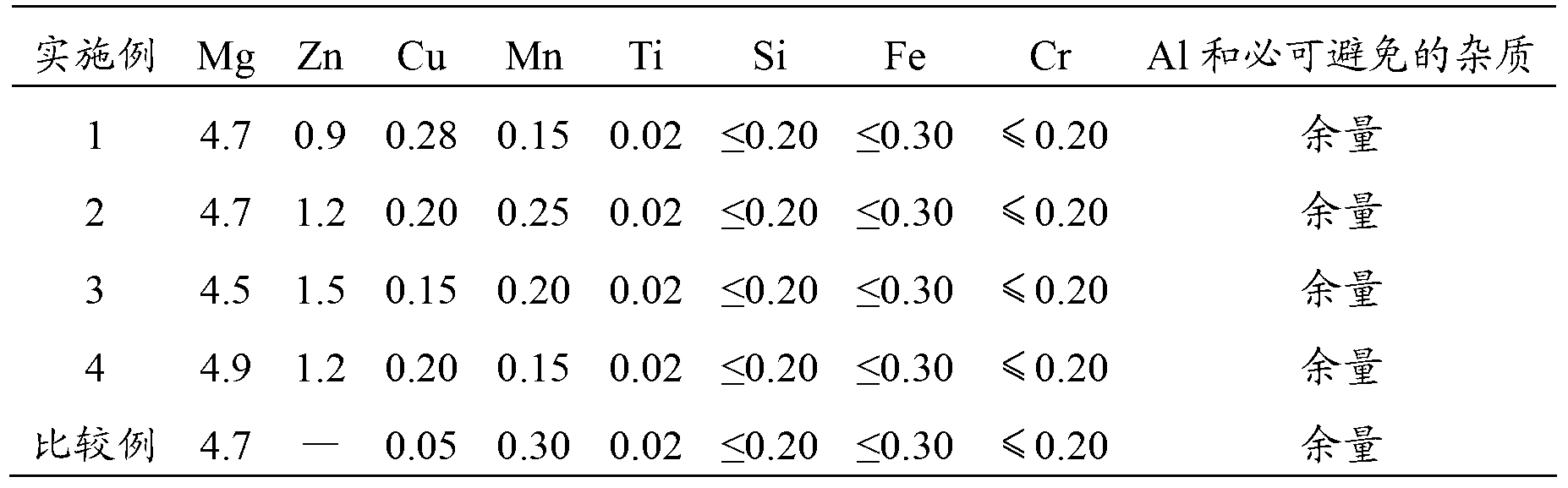

[0088] Al-Mg-Zn-Cu alloys were prepared from various raw materials according to the composition of the alloys in Table 1.

[0089] First put the aluminum ingot into the melting furnace. When the aluminum ingot is melted and the melt temperature is 730°C, add AlCu50, AlMn10 master alloy and Zn to the obtained aluminum melt and add a small amount of covering agent. When the master alloy is completely melted, continue Stir the Al-Cu-Mn-Zn mixed melt; when the temperature of the Al-Cu-Mn-Zn mixed melt drops to 710°C, add Mg to the obtained Al-Cu-Mn-Zn mixed melt, and fully Stirring; then slagging, degassing and refining to obtain Al-Cu-Mn-Zn-Mg mixed melt; when the temperature is at 720°C, add Al-Cu-Mn-Zn-Mg mixed melt 5Ti-B master alloy, stirring and standing for 10 minutes, casting in an iron mold to obtain an ingot;

[0090] The ingot obtained is heated up to 460 DEG C of insulation 16h with furnace and carries out homogenization treatment;

[0091] The homogenized ingot is c...

Embodiment 2~4

[0102] According to the technical solution of Example 1, the components of Examples 2-4 listed in Table 1 were prepared to obtain finished aluminum alloys.

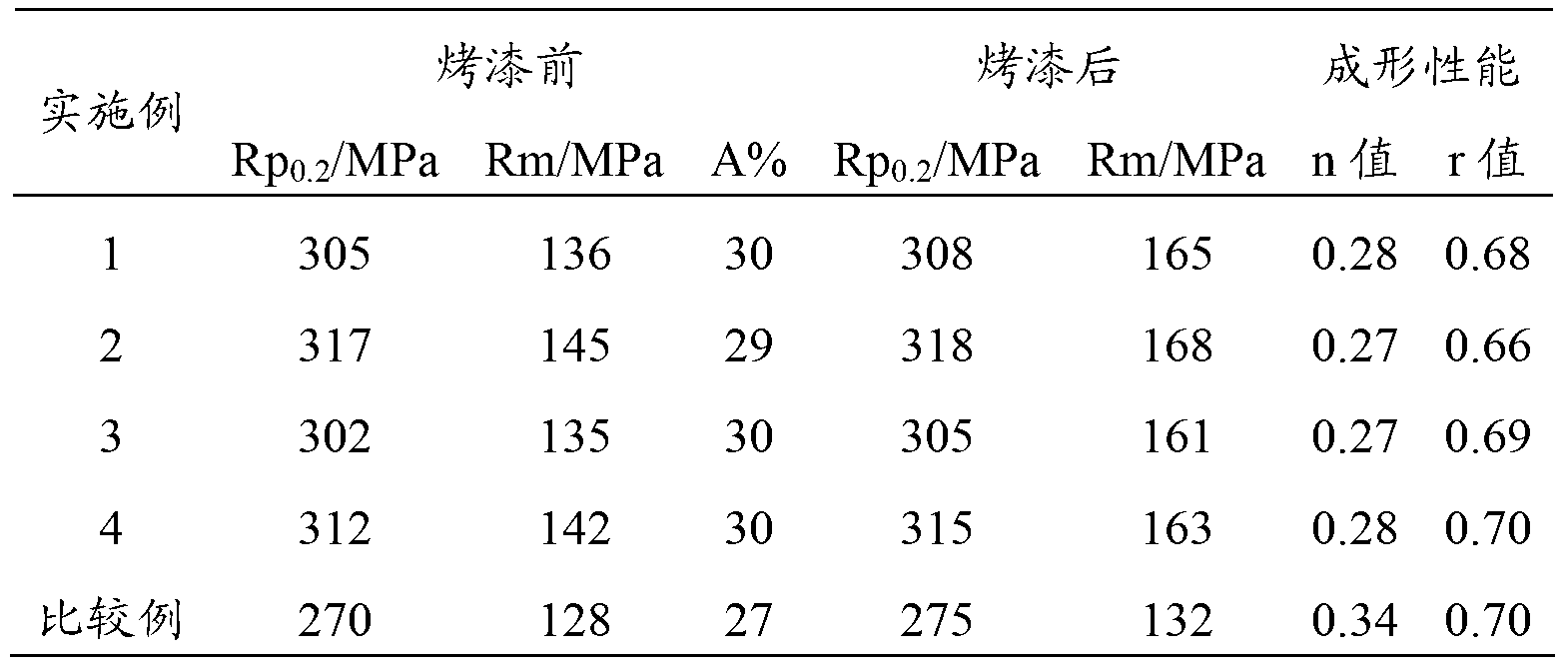

[0103] In the present invention, the obtained aluminum alloy is tested for mechanical properties and formability, and the results are shown in Table 2. Table 2 is the performance test results of the aluminum alloys obtained in the embodiments of the present invention and comparative examples;

[0104] The present invention carries out simulated baking paint test with the aluminum alloy finished product that obtains, and concrete process is as follows:

[0105] The sample is pre-stretched by 2%, then heated at 170° C. for 20 minutes, taken out, and subjected to a tensile test at room temperature after air-cooling. The results are shown in Table 2. Table 2 shows the performance of the aluminum alloys obtained in the embodiments of the present invention and comparative examples Test Results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com