Combined production method for abalone polysaccharide, lipid and protein peptide

A technology of abalone polysaccharides and protein peptides, applied in the field of extracting abalone polysaccharides, lipids and protein peptides, can solve the waste of abalone resources, the economic value and function of abalone viscera are not fully reflected, and the extraction and utilization of abalone protein peptides and lipids are ignored and other issues, to achieve the effects of reducing production costs, easy absorption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Enzymolysis: Add 1L of pure water to 1kg of cleaned abalone viscera, adjust the pH to 8.0 with alkali, add 1g of trypsin and 1g of collagenase, stir and incubate at 45°C for 6 hours, then Adjust the pH to 7.0 with acid, add 10 g of neutral protease, stir and insulate the enzymolysis at 45°C for 6 hours, filter and remove insoluble matter, and obtain the enzymatic hydrolysis solution of abalone viscera.

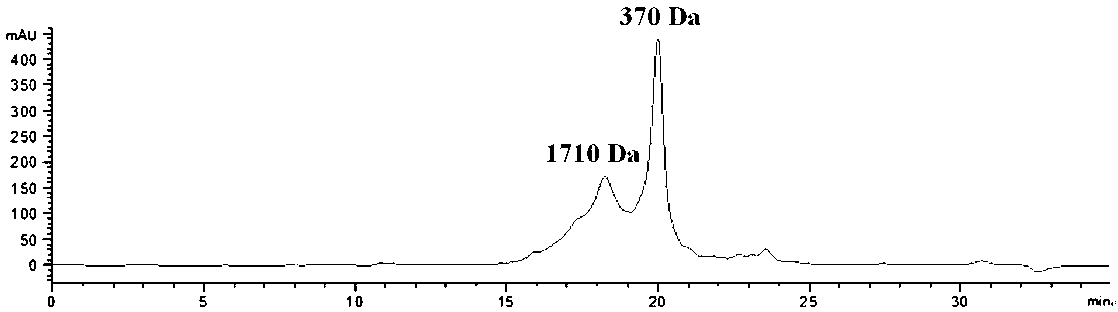

[0030] (2) Membrane separation: the obtained abalone viscera enzymolysis solution is separated by a 5000 Dalton ultrafiltration membrane, the enzymolysis solution intercepted by the ultrafiltration membrane is a concentrated solution, and the enzymolysis solution passing through the ultrafiltration membrane is a dialysis solution. liquid.

[0031] (3) Alcohol precipitation: Add 2.5L of 99.5% alcohol to the 850ml concentrated solution obtained by the ultrafiltration membrane, let it settle at room temperature for 8 hours, and obtain 105g of polysaccharide precipitate...

Embodiment 2

[0036] (1) Enzymolysis: Add 1L of pure water to 1kg of cleaned abalone viscera, adjust the pH to 9.0 with alkali, add 5g of trypsin and 5g of collagenase, stir and incubate at 50°C for 4 hours, then Adjust the pH to 6.0 with acid, add 20 g of bromelain, stir and incubate the enzyme for 3 hours at 50°C, then filter and remove insoluble matter to obtain the enzymolysis solution of abalone viscera.

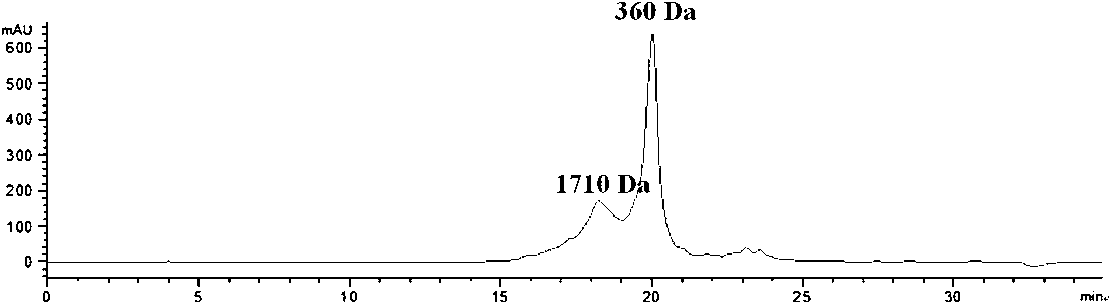

[0037] (2) Membrane separation: The obtained abalone viscera enzymatic solution is separated by a 10,000-dalton ultrafiltration membrane. The enzymatic solution intercepted by the ultrafiltration membrane is a concentrated solution, and the enzymatic solution that passes through the ultrafiltration membrane is a dialysis solution. liquid.

[0038](3) Alcohol precipitation: Add 3.0L of 99.5% alcohol to the 800ml concentrated solution obtained by the ultrafiltration membrane, let it stand at room temperature for 10 hours, and obtain 100g of polysaccharide precipitation by centrifugatio...

Embodiment 3

[0043] (1) Enzymolysis: Add 1L of pure water to 1kg of cleaned abalone viscera, adjust the pH to 8.5 with alkali, add 10g of trypsin and 10g of collagenase, stir and incubate at 50°C for 6 hours, then Adjust the pH to 5.0 with acid, add 5g of bromelain, stir and incubate the enzymolysis at 50°C for 3 hours, filter and remove insoluble matter, and obtain the enzymolysis solution of abalone viscera.

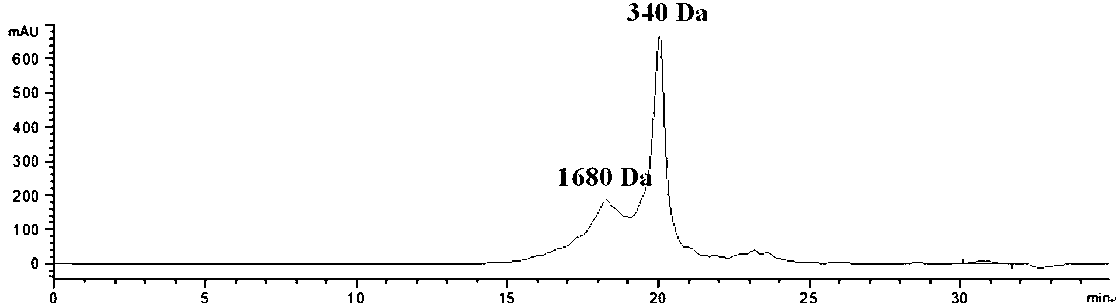

[0044] (2) Membrane separation: The obtained abalone viscera enzymatic solution is separated by a 20,000 Dalton ultrafiltration membrane. The enzymatic solution retained by the ultrafiltration membrane is a concentrated solution, and the enzymatic solution that passes through the ultrafiltration membrane is a dialysis solution. liquid.

[0045] (3) Alcohol precipitation: Add 3.0L of 99.5% alcohol to the 750ml concentrated solution obtained by the ultrafiltration membrane, let it stand at room temperature for 12 hours, and obtain 107g of polysaccharide precipitate by centrifugation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com