Combined treatment method of 1,4-butanediol production wastewater

A technology for the production of wastewater and butanediol, which is applied in natural water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of easily inhibited microbial activity in reactors, unstable effluent quality, and low impact resistance and other problems, to achieve the effect of benefiting subsequent biochemical treatment, improving the impact resistance of water volume and water quality, and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

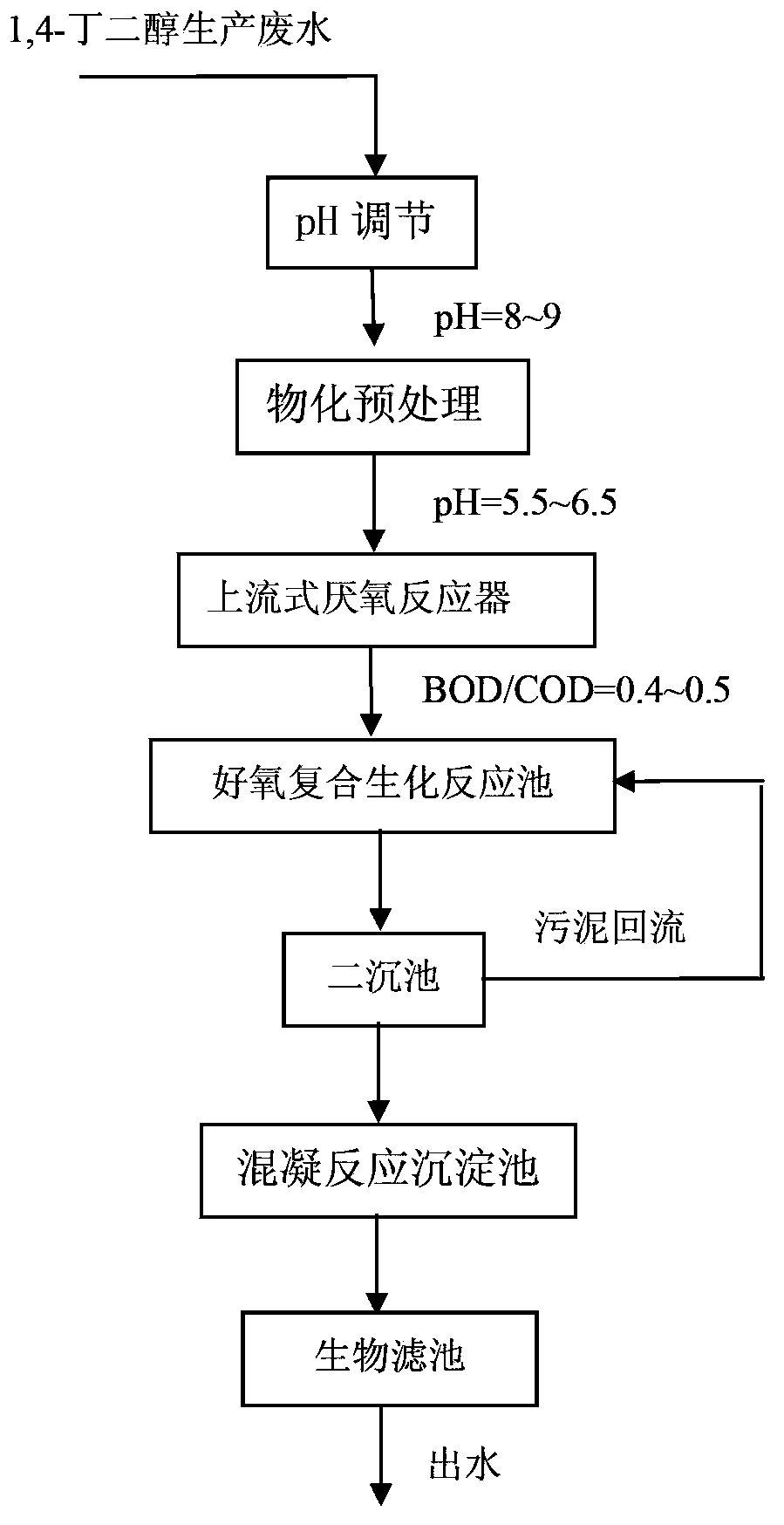

[0028] see figure 1 .

[0029] A 1,4-butanediol production wastewater volume is 3600m 3 / d. The main sources of wastewater are: 1. Wastewater from deionization device; 2. Wastewater from acetylene workshop; 3. Wastewater from butanol tower and methanol plant in 1,4-butanediol plant; 4. Activation of catalyst and 1,4-butanediol plant area water etc.

[0030] The first step, physical and chemical preprocessing

[0031] A. Preparation of mixed acid, measure acetic acid:hydrochloric acid=3:7 volume ratio, mix well to get mixed acid, set aside.

[0032] B, Pre-optimization of wastewater quality, adding mixed acid to the 1,4-butanediol production wastewater to be treated, the amount of mixed acid is based on the pH value of the wastewater being 8-9; then, at 1,4-butanediol per liter Add 50-100 mg of polyferric sulfate and 2-5 mg of polyacrylamide into the 4-butanediol production wastewater, use stepless speed-variable mechanical stirring and coagulation reaction, precipitate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com