Numerical control rubbing type grinding machine tool

A machine tool and bridge technology, applied in the mechanical field, can solve the problems of high labor intensity, low production efficiency and long processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

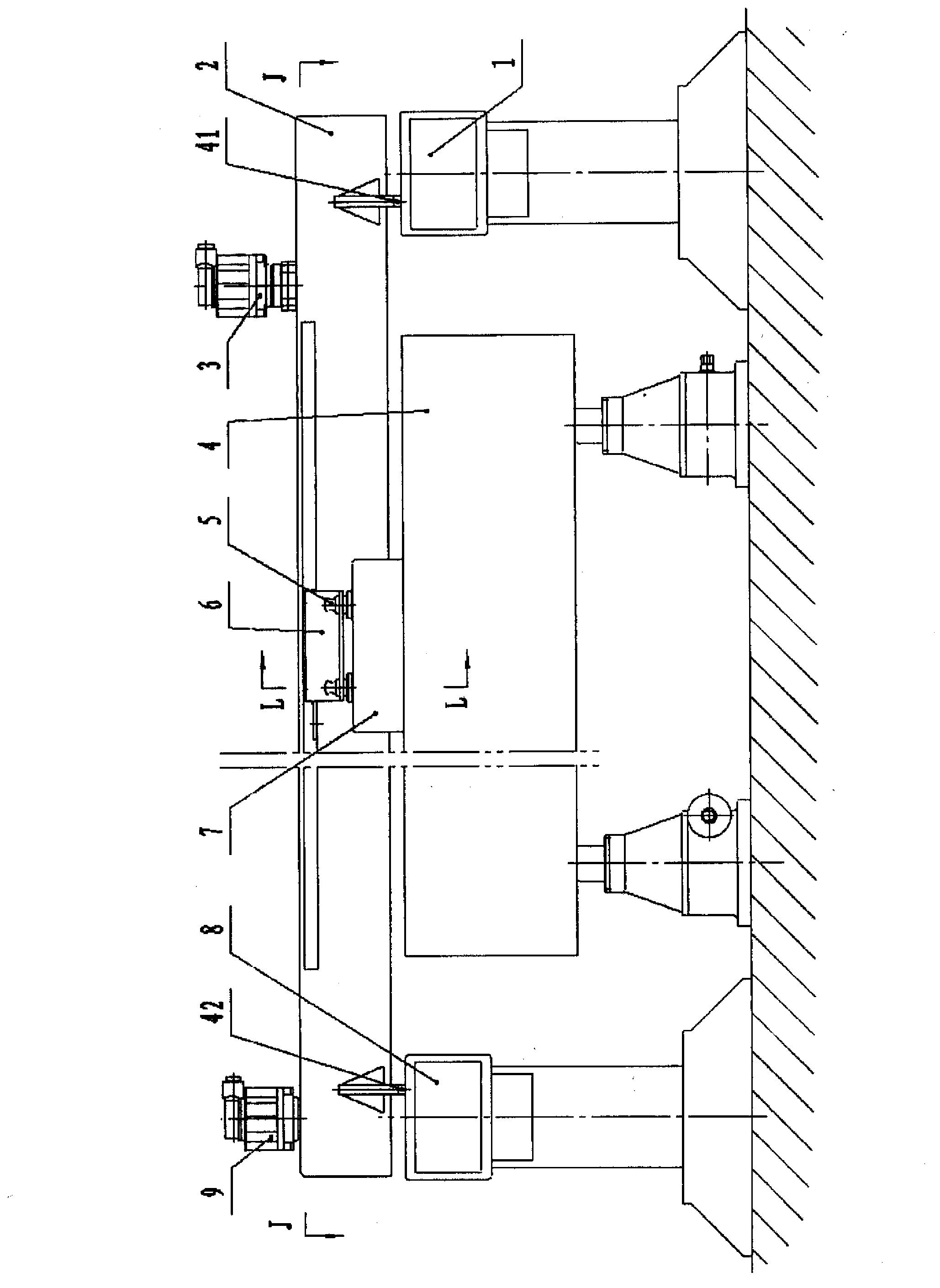

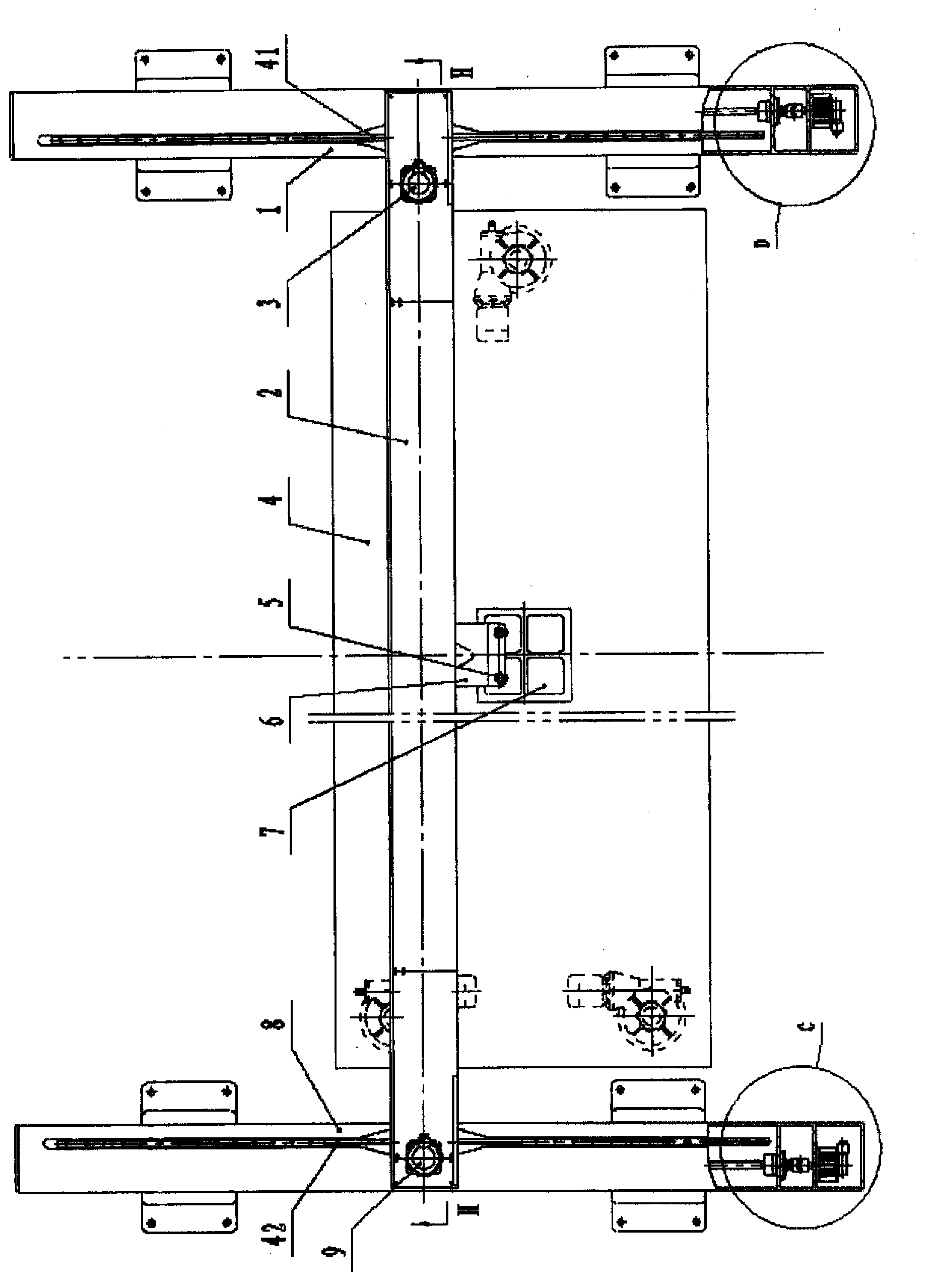

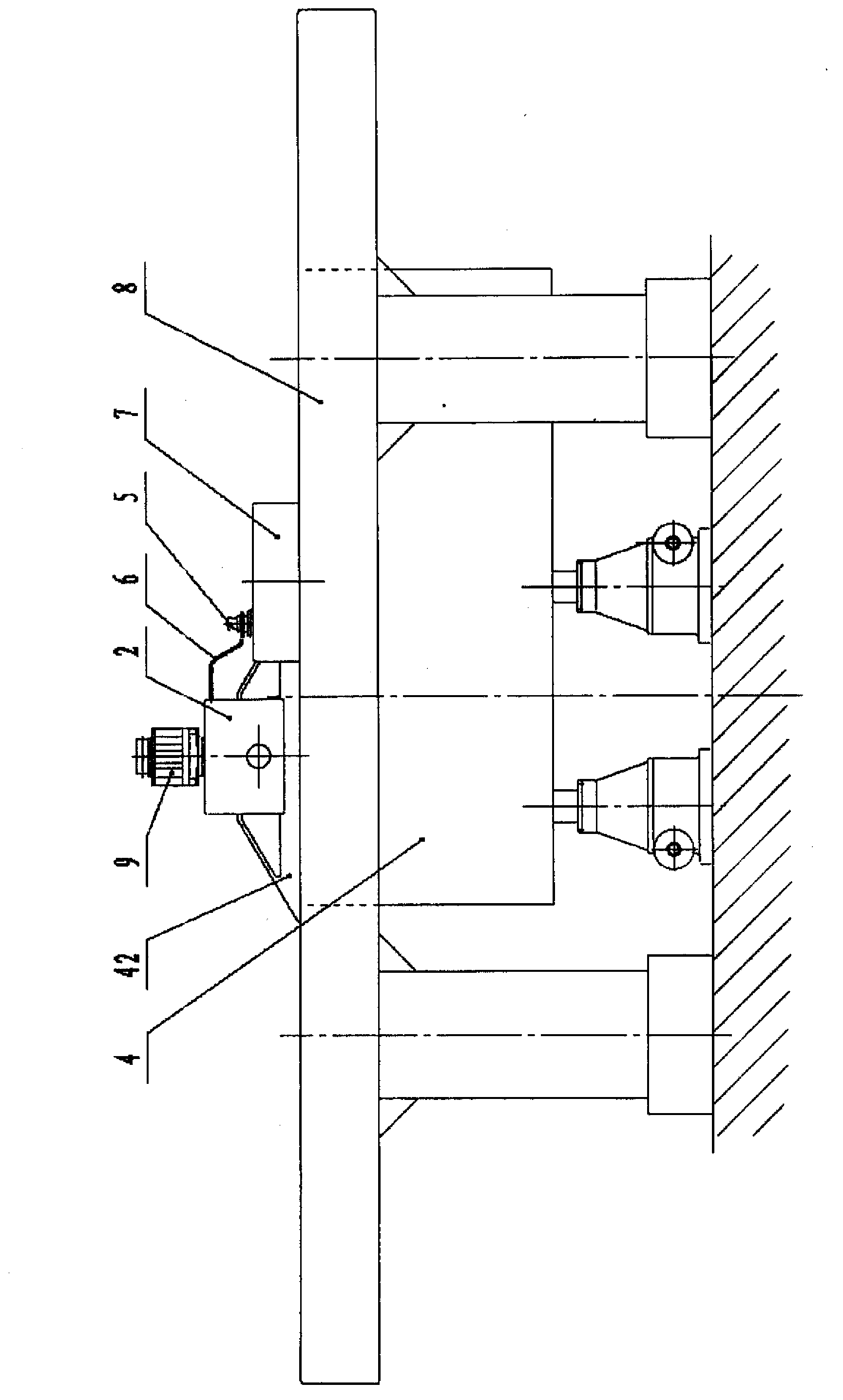

[0019] Such as Figures 1 to 11 As shown in the figure, the CNC kneading grinding machine is composed of a left bracket (8), a right bracket (1), and a beam (2) to form a bridge frame structure; the left side of the workpiece (4) is the left bracket (8), and the right side is the right bracket (1), the beam (2) is placed above the left bracket (8) and the right bracket (1); the left leg (42) and the right leg (41) protrude from the bottom of the two ends of the beam (2), respectively, and the left leg (42) Connect with the left guide rail (17), the left guide rail (17) is fixed on the left support (8), the right supporting foot (41) is connected with the right guide rail (23), the right guide rail (23) is fixed on the right support (1 ); above the workpiece (4) is the research plate (7), and the research plate (7) passes through the latch (5), the pulley (6), the first shaft (38), the second shaft (39), the first swing arm (12), the second swing arm (13) is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com