Full-automatic paper money clearing and packaging assembly line

A banknote sorting, fully automatic technology, applied in packaging automatic control, packaging, packaging protection and other directions, can solve the problems of low work efficiency, large use of personnel, high management costs, and achieve the effect of high production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

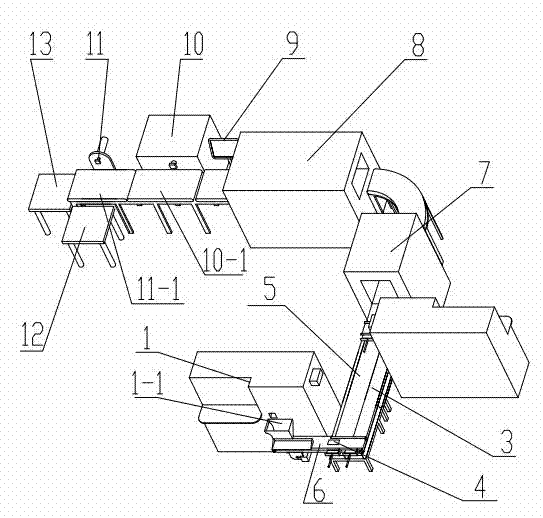

[0013] A fully automatic banknote sorting and plastic bag assembly line, the structure includes a sorting and binding machine 1 set up in sequence according to the process flow and controlled by the main control management unit, a banknote sorting and conveying mechanism, a stacking and wrapping machine 7, and plastic packaging Machine 8, the post-sequence detection and sorting mechanism, and the conveyor belt and supporting position sensor arranged between each mechanism, the important thing is: the banknote sorting and conveying mechanism between the sorting and binding machine 1 and the stacking and wrapping machine 7 It is the sorting transmission channel formed by the intermediate conveyor belt and the parallel double-channel conveyor belt by means of a bridge connection.

[0014] In the described sorting transmission channel structure, include the conveyor belt 6 arranged below the banknote outlet of the sorting and binding machine 1, the ATM banknote conveyor belt 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com