Welding method achieving medium thick plate backing welding without back gouging

A welding method and bottom welding technology, which is applied to welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of unsuitable robot automatic welding, unclear root welding of medium and thick plate bottom welding, low efficiency, etc., and achieve easy robot The effect of automatic welding, reducing serious deformation and simplifying welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

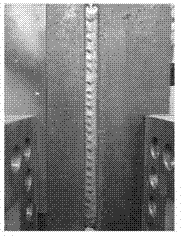

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0023] A welding method of the present invention for realizing root-clearing of medium-thick plates, generally speaking, includes two steps of rooting welding and filling welding. Among them, double-sided double-arc asymmetric welding is used for backing welding, double-sided double-arc symmetrical welding is used for filling welding, and MAG welding (Metal Active Gas Welding, metal active gas welding) is preferably used for both backing welding and filling welding.

[0024] During rooting welding, the arc distance between the front arc and the back arc is 20 to 40 mm, and the two welding torches are welded at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com