Oil absorbent prepared from low grade diatomite and preparation method thereof

A diatomaceous earth and oil-absorbing agent technology, which is applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of occupying large areas of forest land and agricultural land, waste of resources in the environment, and disorderly stacking, so as to facilitate recycling and Effects of post-processing, low bulk density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

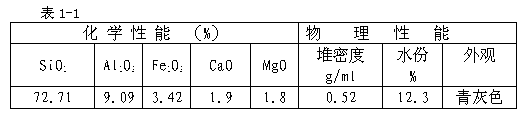

[0028] ①. Select low-grade diatomite, see Table 1-1 for physical and chemical indicators, and reserve.

[0029]

[0030] ②. Crush and pulverize the diatomaceous earth in step ①, with an average particle size of 22μ.

[0031] ③. Take 200g of diatomite crushed in the above step ②, add 600ml of water, add sulfuric acid, the acid dosage is 110g of 96% sulfuric acid, the temperature of water bath is 100℃, stir for 3h for acidification reaction, add 600ml of water, stir for 1h, settle Suction filtration to obtain 170 g of acidified diatomite.

[0032] ④. Take 125g of acidified diatomite in step ③, add 500 ml of water, the liquid-solid ratio is 4, repeatedly stir, filter, repeat washing 3 times, each time for 20 minutes, and suction filter to obtain 105g of acidified washed diatomite.

[0033] ⑤. Dry 100 g of acidified and washed diatomaceous earth in step ④ at 110±5°C for 1 hour.

[0034] 6. Take 60 g of diatomite treated in the above steps 5. Add 1.8 g of Na 2 CL (industrial ...

Embodiment 2

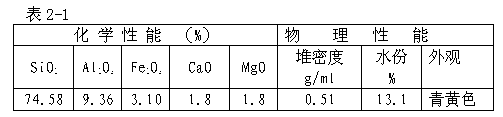

[0041] ①. Select low-grade diatomite, see Table 2-1 for physical and chemical indicators, and reserve.

[0042]

[0043] ②. Crush and pulverize the diatomaceous earth in step ①, with an average particle size of 24μ.

[0044] ③. Take 400g of the pulverized diatomite in the above step ②, add 1200ml of water, add sulfuric acid, the acid dosage is 220g of 96% sulfuric acid, the temperature of the water bath is 100°C, stir for 3h for acidification reaction, add 1200ml of water, stir for 1h, settle and pump Filter to obtain 350 g of acidified diatomaceous earth.

[0045] ④. Take 300g of acidified diatomite in step ③, add 1200 ml of water, the liquid-solid ratio is 4, repeatedly stir, filter, repeat washing 3 times, each time for 20 minutes, and suction filter to obtain 273g of acidified washed diatomite.

[0046] ⑤. Dry the acidified and washed diatomaceous earth in step ④ at 110±5°C for 1 hour.

[0047] 6. Take 200g of diatomite treated in the above steps 5. Add 8g of Na 2 CL (...

Embodiment 3

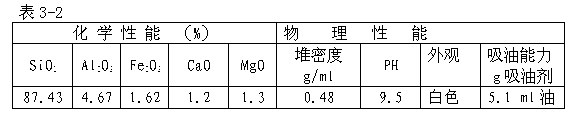

[0053] ①. Select low-grade diatomite, see Table 3-1 for physical and chemical indicators, and reserve.

[0054]

[0055] ②. Crush and pulverize the diatomaceous earth in step ①, with an average particle size of 21μ.

[0056] ③. Take 400g of diatomite pulverized in the above step ②, add 1200 ml of water, add sulfuric acid, the amount of acid is 220g of 96% sulfuric acid, the temperature of water bath is 100°C, stir for 3h for acidification reaction, add 1200ml of water, stir for 1h, settle Suction filtration to obtain 344 g of acidified diatomaceous earth.

[0057] ④. Take 300g of acidified diatomite in step ③, add 1200 ml of water, the liquid-solid ratio is 4, repeatedly stir, filter, repeat washing 3 times, each time for 20 minutes, and suction filter to obtain 260g of acidified washed diatomite.

[0058] ⑤. Dry the acidified and washed diatomaceous earth in step ④ at 110±5°C for 1 hour.

[0059] 6. Take 200g of diatomite treated in the above step 5. Add 10g of Na 2 CL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com