Fixing method of superhard tool and hard contact

A technology of hard contacts and superhard tools, which is applied in the direction of manufacturing tools, striking tools, light impact tools, etc., and can solve the problems of hard contacts being damaged, falling off, and superhard contacts falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

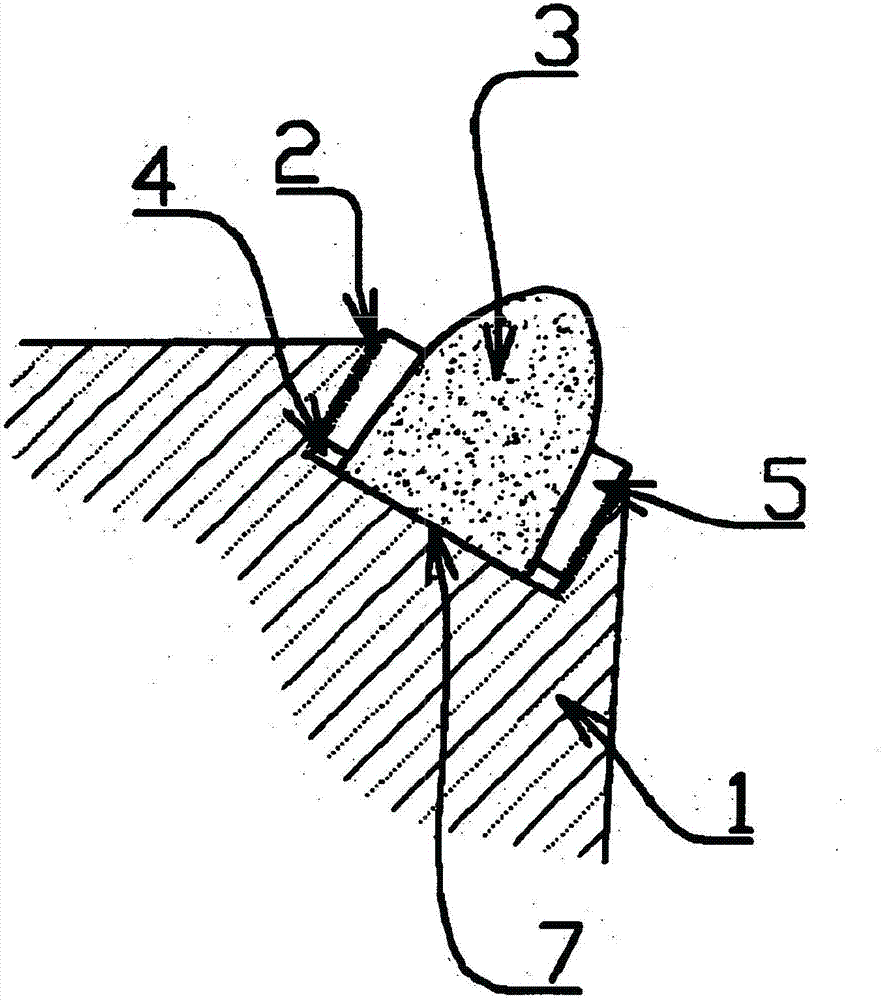

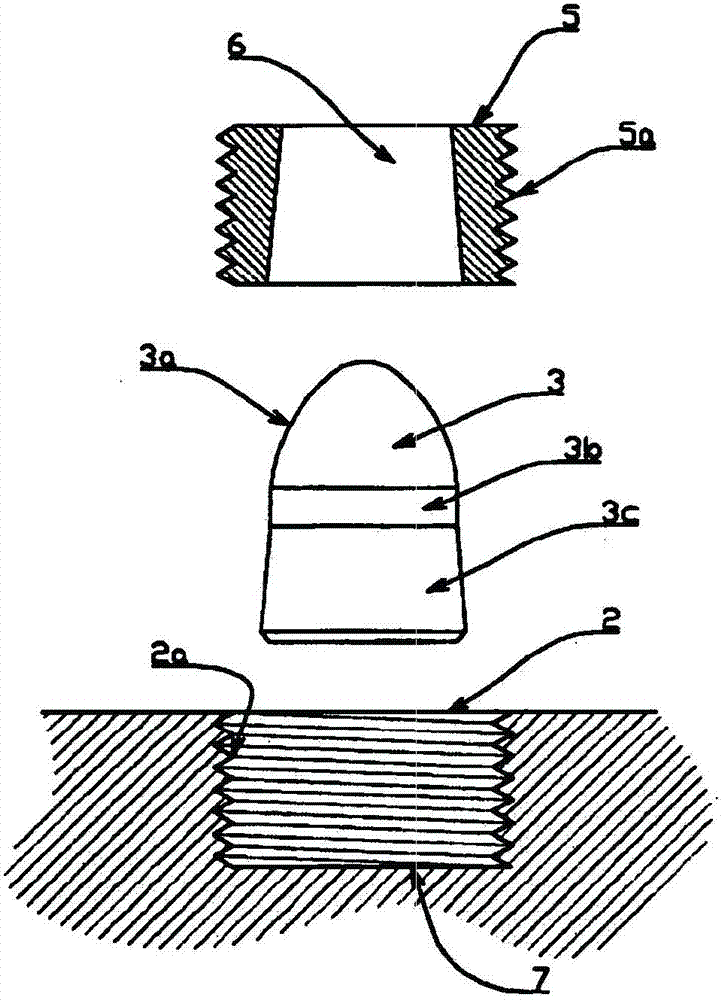

[0026] figure 1 The superhard tool of the present invention is shown as an example, in which a base portion of a hard contact 3 (in this case, a superhard contact) is fitted into a contact hole 2 provided in the head portion of a steel base 1 . The bottom surface of the contact 3 is in close contact with the bottom surface 7 of the contact hole 2 .

[0027] Such as figure 2 As shown, the hard contact 3 is composed of a head portion 3a, a body portion 3b, and a base portion 3c. The head portion 3a is formed in a substantially cannonball shape with a small diameter at the front end and a large diameter at the body portion side. The main body 3b has a cylindrical shape with the same diameter, and the base 3c is formed as an inclined surface having a conical cross section with a smaller diameter on the main body side and a gradually larger diameter on the base side.

[0028] The inner diameter of the contact hole 2 of the base body 1 is larger than the outer diameter of the lar...

Embodiment 2

[0034] then, Figure 7 , Figure 8 It is a figure which shows the embodiment slightly different from the above-mentioned, and in this Example, the base part of the hard contact 3 is integrally formed with the flange 31. The outer diameter of this flange 31 is substantially the same as the inner diameter of the contact hole 2, and its height is several millimeters, on which a pressing ring 5 is screwed, and the lower surface of the pressing ring 5 is in close contact with the upper surface of the above-mentioned flange 31. In this way, since the flange 31 integrated with the hard contact 3 is pressed by the pressing ring 5, the fixing of the hard contact 3 can be made more reliable.

Embodiment 3

[0036] then, Figure 9 , Figure 10It is a figure which shows the reference example different from the above, and in this example, the male thread 14 is provided directly in the outer peripheral part of the base part of the hard contact 13. As shown in FIG. The hard contact 13 is directly screwed into the contact hole 2 engraved with a female thread. That is, the hard contact 13 is screwed directly to the base 1 . While it is often possible to thread the part to the base material, hard contacts are generally brittle and cannot be secured by threads. However, since the tools used for the opening of the milling hole are mostly discarded after being used once, this threaded fastening method can be used. Although it is also possible to form a male thread on the hard contact itself as described above, it is generally difficult to form a threaded portion on such a hard contact. It is ideal for practical use.

[0037] As explained above, according to the method for fixing hard c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com