Fan tower vibration control system and control system for increasing fan cut-out wind speed

A technology of vibration suppression and vibration acceleration, applied in the control of wind turbines, machines/engines, wind turbines, etc., can solve problems such as first-order natural frequency vibration faults, fatigue load increase, unit vibration faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

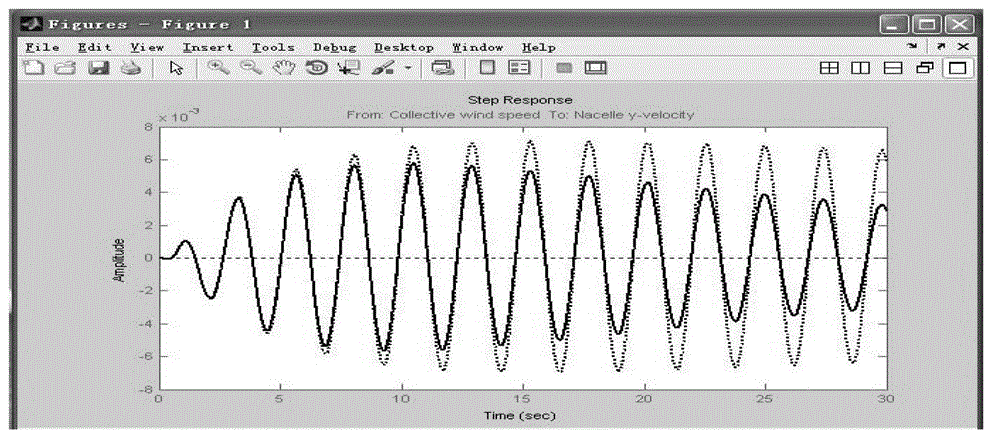

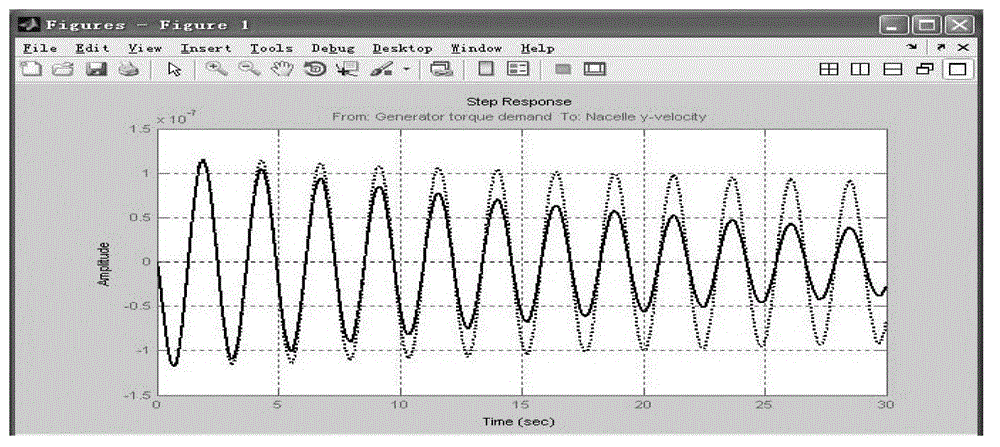

[0077] figure 1 is a block diagram showing a wind tower side-side direction vibration suppression system according to the first embodiment of the present invention. The first embodiment of the present invention is mainly aimed at suppressing vibration in the side-side direction of the wind turbine tower.

[0078] refer to figure 1 , the side-side direction vibration suppression system of the wind turbine tower includes a generator speed measurement module (not shown), a comparator 101, a proportional-integral (PI) controller 102, an acceleration measurement module (not shown), an integration module 103, a Pass filter 104, proportional gain module 105, adder 106.

[0079] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com