Wind-driven generator blade capable of realizing sectioned furling

A wind generator, segmented technology, applied in the direction of wind turbines consistent with the wind direction, wind turbines, monitoring of wind turbines, etc., can solve problems such as loss of power generation, to increase power generation, increase power generation, reduce The effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific examples.

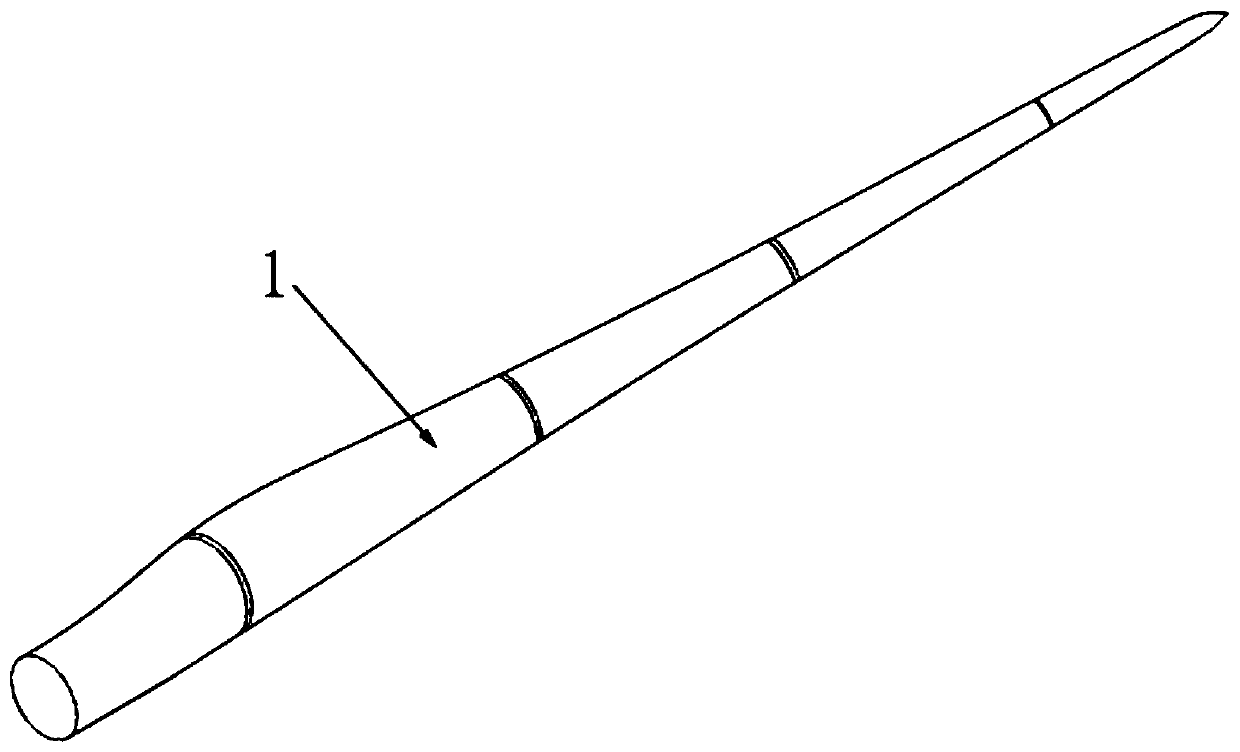

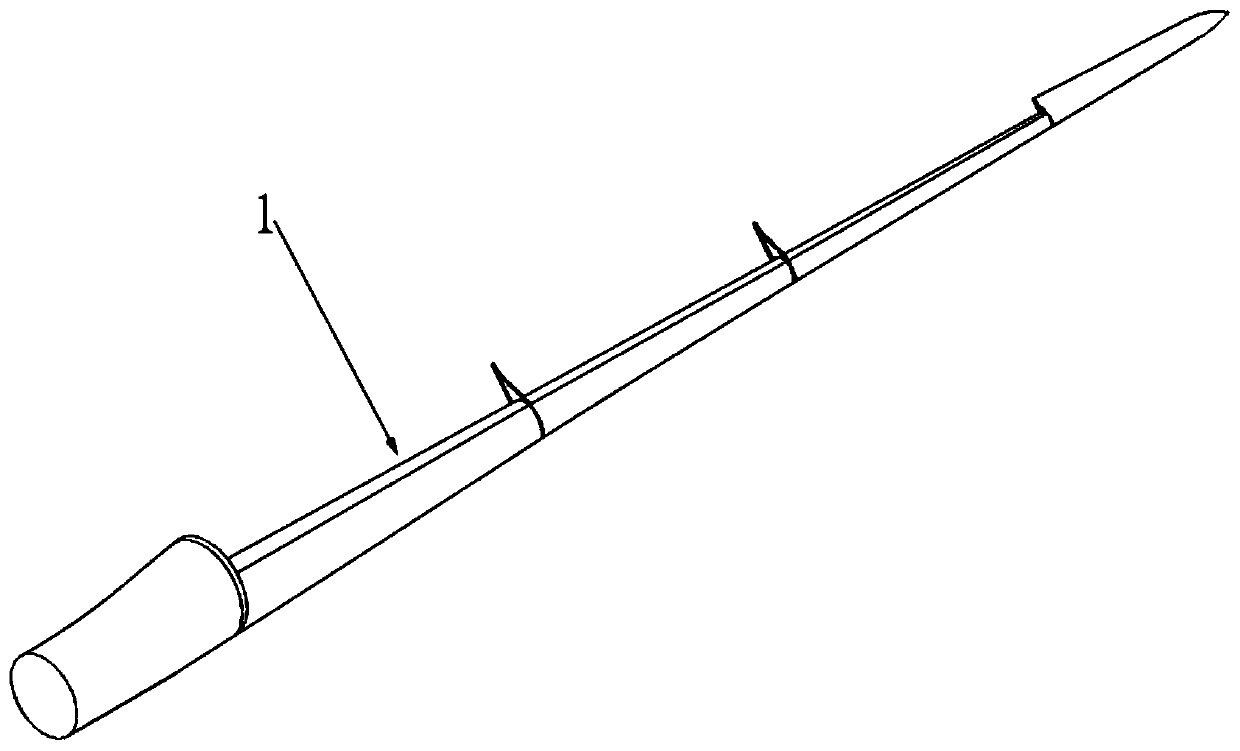

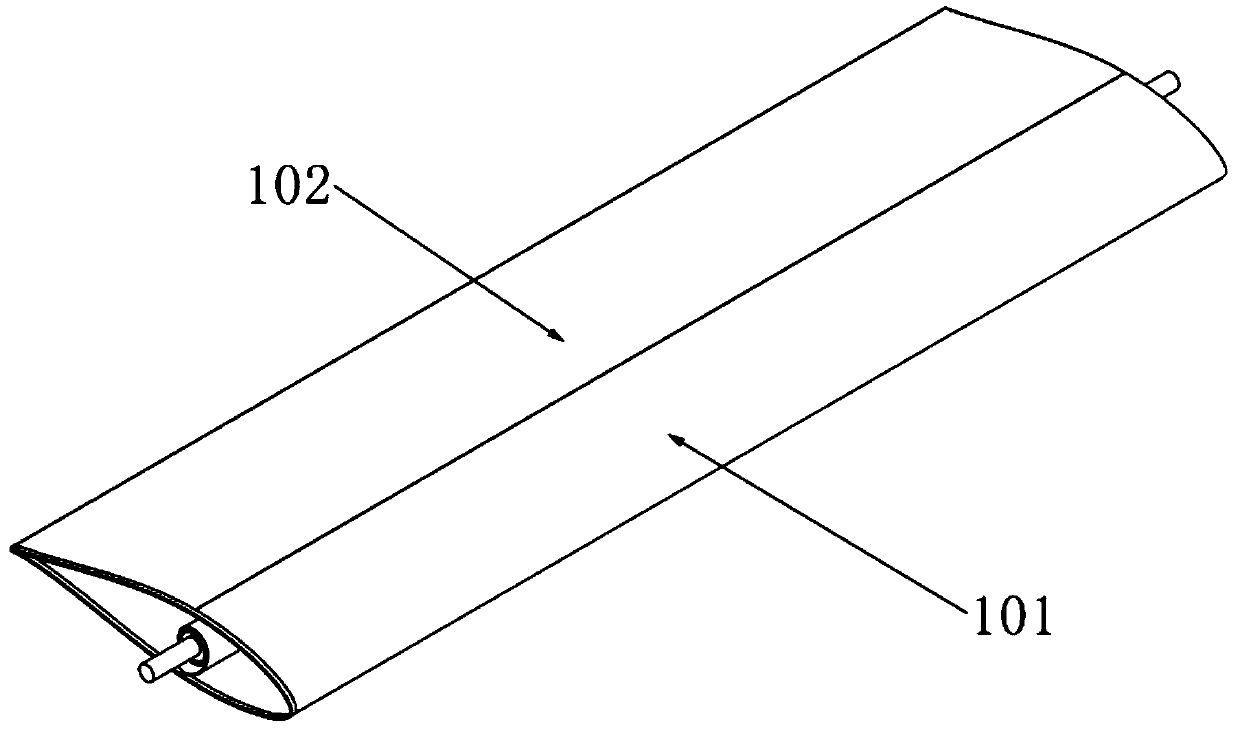

[0019] Such as Figure 1 to Figure 7 As shown, the segmented retractable wind turbine blade described in this embodiment includes a blade body, and a plurality of sequentially connected blade segment units 1 are arranged between the blade root and the blade tip of the blade body. The interior of each blade segment unit 1 is provided with a reel 2 extending along its length direction. The front edge portion 101 of the blade segment unit 1 is fixed, and its trailing edge portion 102 is retractable. One side of the retractable trailing edge portion 102 is connected to the reel 2, the other side is placed on the leading edge portion 101, and its two ends are respectively slidably installed on the guide rails 3 at both ends of the blade segment unit 1. The track of the guide rail 3 adapts to the profile shape of the airfoil of the blade segment unit 1, and the rotation of the reel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com