Region electrolysis prebaking aluminum cell

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve the problems of complex processing of special-shaped cathodes, difficulty in replacement and repair, and large impact on electrolytic cells, and achieve low replacement and maintenance, simple processing, and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

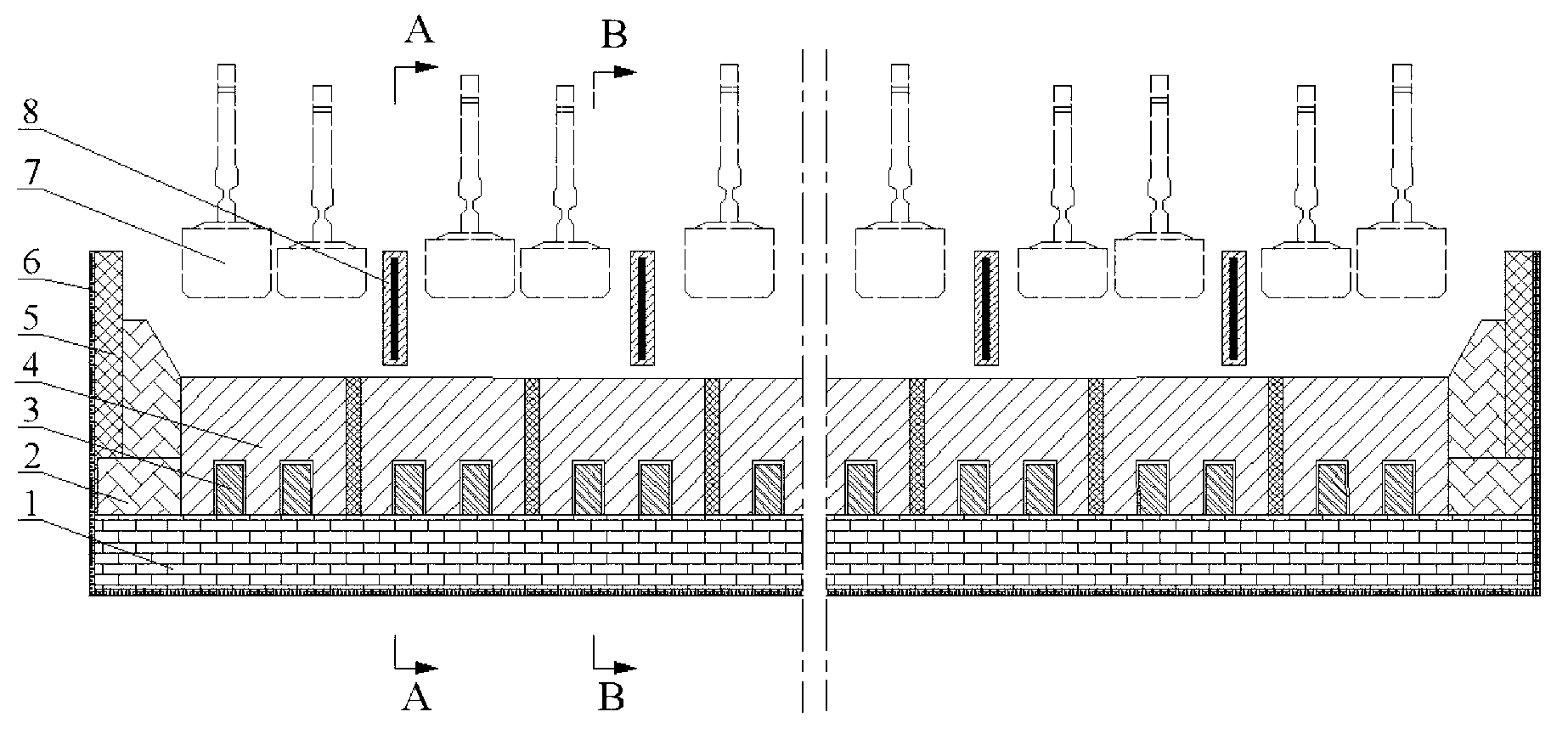

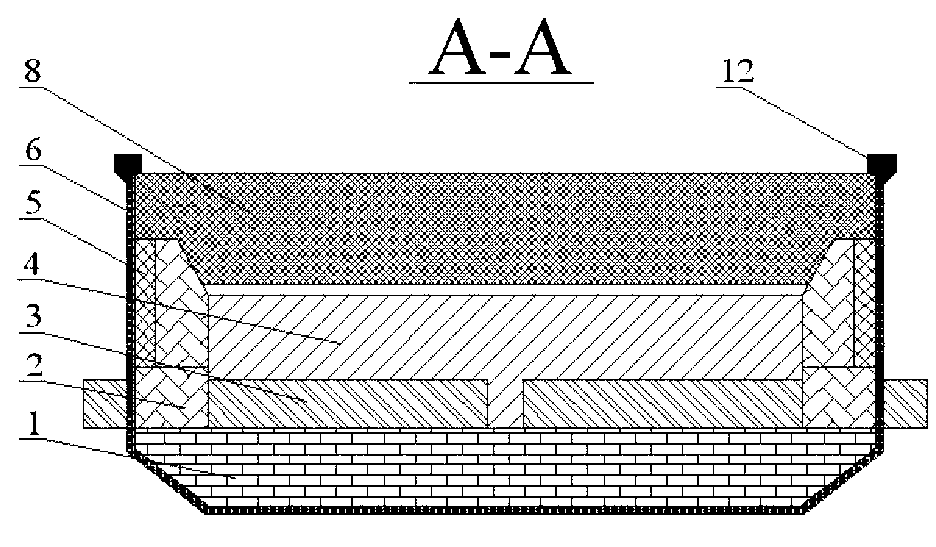

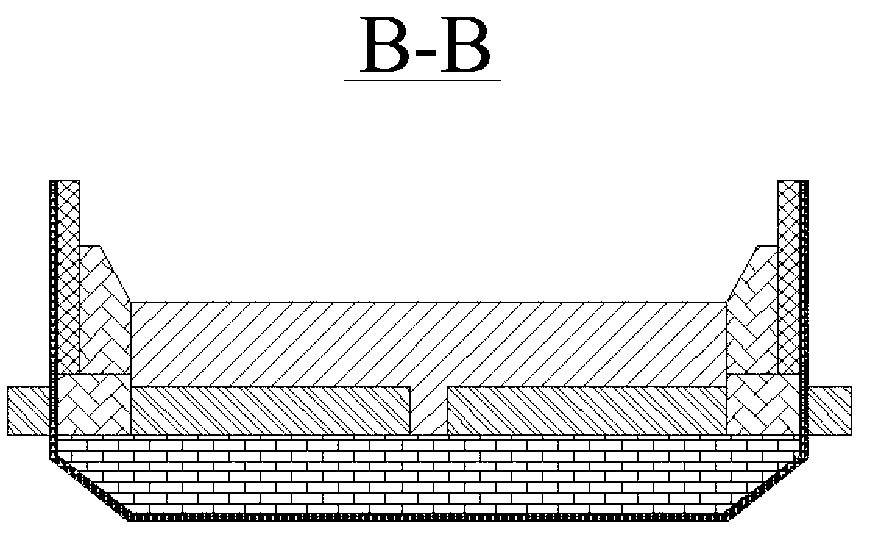

[0036] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the electrolytic cell of the present invention having a partition plate in an area not in contact with the cathode is composed of a bottom refractory insulation material 1, a side insulation material 2, a cathode steel rod 3, a cathode 4, a side carbon block 5, a tank shell 6, and an anode 7. Composed of the area dividing plate 8 and the fixing device 12 for the dividing plate. Among them, the area dividing plate 8 is installed in the direction perpendicular to the length of the tank, and each electrolytic cell has at least 3 to 10 dividing plates (such as Figure 4 As shown), the area dividing plate 8 divides the entire electrolytic cell melt working area into several small areas, and the electrolytic cell is equipped with at least one feeder in each partition. The thickness of the area dividing plate 8 is 10cm~40cm, the height is the depth of the groove or slightly smaller, and the length is slightly...

Embodiment 2

[0038] Such as Figure 5 with Image 6 As shown, the electrolytic cell of the present invention having a region dividing plate with a small-sized aluminum communication hole in contact with the cathode is composed of a bottom refractory insulation material 1, a side insulation material 2, a cathode steel rod 3, a cathode 4, and a side carbon block 5. The tank shell 6, the anode 7, the area dividing plate 8, the small-sized aluminum communication hole 9 on the dividing plate and the dividing plate fixing device 12 are composed. Among them, the area dividing plate 8 is installed in the direction perpendicular to the length of the tank, and each electrolytic cell has at least 3 to 10 dividing plates (such as Figure 5shown); the area dividing plate 8 divides the entire electrolytic cell melt working area into several small areas, and the electrolytic cell is equipped with at least one feeder in each partition. The area dividing plate 8 has a thickness of 10cm to 40cm, a height ...

Embodiment 3

[0040] Such as Figure 7 with Figure 8 As shown, the electrolytic cell of the present invention having a region dividing plate with a large-sized aluminum communication hole in contact with the cathode is composed of a bottom refractory insulation material 1, a side insulation material 2, a cathode steel rod 3, a cathode 4, and a side carbon block 5. The tank shell 6, the anode 7, the area dividing plate 8, the large-size aluminum communication hole 10 on the dividing plate and the dividing plate fixing device 12 are composed. This electrolyzer is different from Embodiment 2 except that the size, quantity and distribution of the aluminum communication holes are different, and the others remain the same. In this embodiment, a row of 2 to 8 large-sized aluminum communication holes 10 on the partition plate with a larger size of circular, regular triangle or regular polygon is opened at the bottom of the partition plate 8, and the partition plate The diameter of the circumscri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com