Method for extracting taro starch and application of taro starch

An extraction method and technology of taro, applied in the field of extraction of taro starch and preparation of taro modified starch, can solve the problems hindering the industrial application of modified taro starch, achieve remarkable degreasing effect, improve stability and fluidity, and improve purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

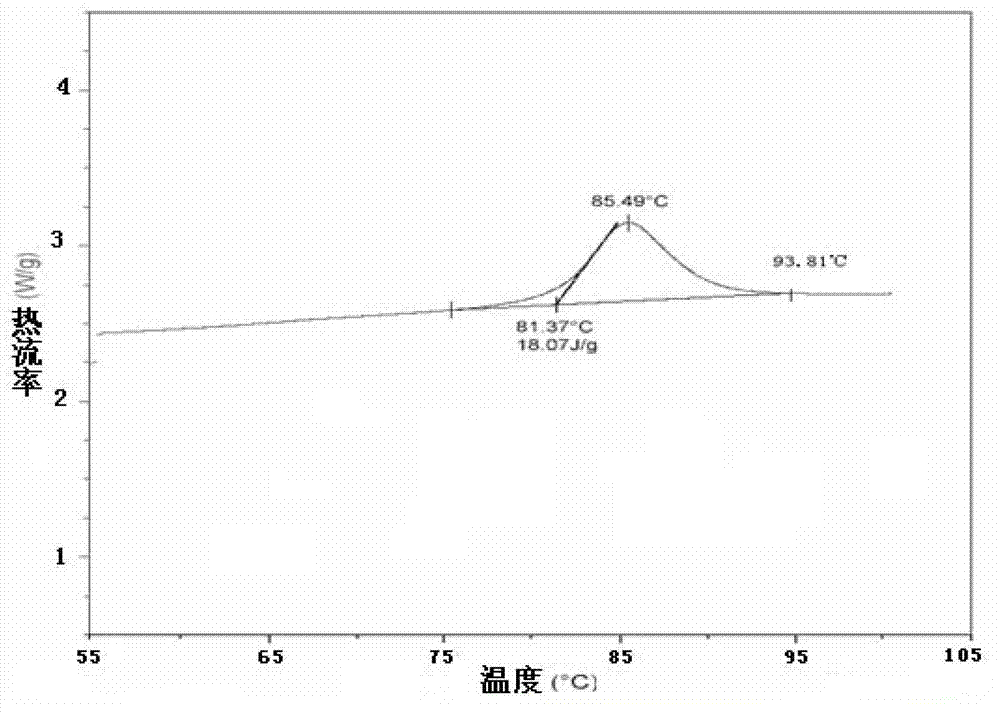

Embodiment 1

[0019] A method for extracting taro starch, specifically comprising the following steps:

[0020] Peel the taro, wash it, slice it, soak it in ammonia solution for 3 minutes, take it out and grind it, put the taro powder in the ammonia solution for 3 hours, pass through a 250-mesh sieve to get the filtrate, wash the solid residue obtained by filtration and pass it through a 200-mesh sieve. Take the filtrate after the mesh sieve, combine the filtrates obtained twice, centrifuge the filtrate at 3000r / s for 15min, wash the precipitate obtained by centrifugation, then centrifuge at 3000r / s for 15min, then wash the precipitate obtained by centrifugation with water and centrifuge under the same conditions Repeat the operation several times, place the final centrifuged precipitate in an oven at 45°C to dry to obtain coarse dry starch, crush the coarse dry starch, degrease with methanol with a volume fraction of 85% for 22 hours, and degrease with absolute ethanol for 7 hours, Put it ...

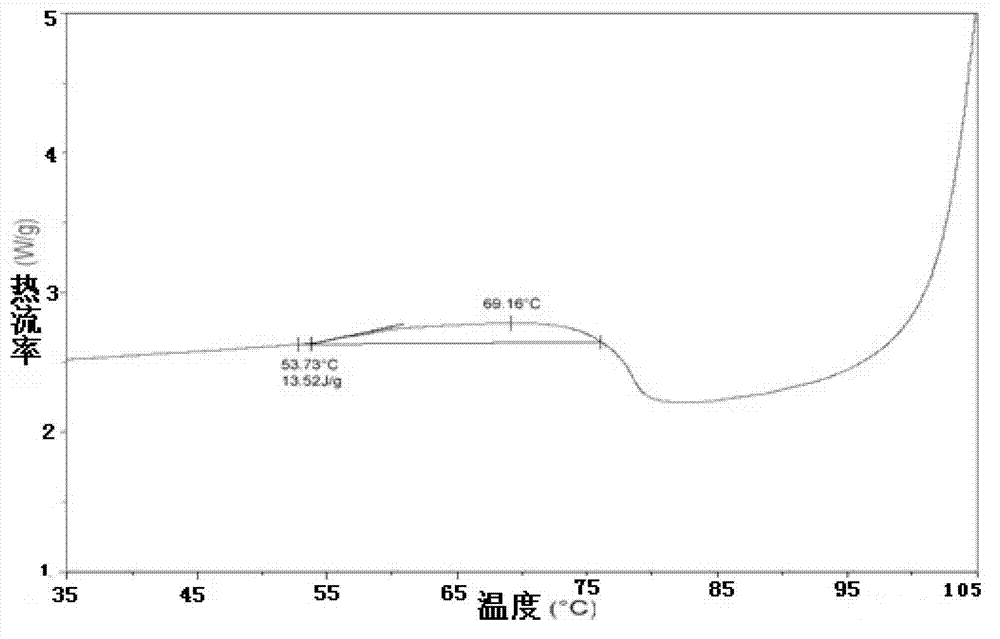

Embodiment 2

[0022] With embodiment 1, its difference is:

[0023] (1) After washing the skin and slicing the taro, soak it in the ammonia solution for 2 minutes, take it out and grind it, put the taro powder in the ammonia solution and continue soaking it for 2 hours, and pass through a 200-mesh sieve to get the filtrate;

[0024] (2) Dry the final centrifuged precipitate in an oven at 40°C to obtain rough dry starch. After crushing the rough dry starch, degrease with methanol with a volume fraction of 85% for 20 hours, then degrease with absolute ethanol for 6 hours, and place in Dry in an oven at 40°C.

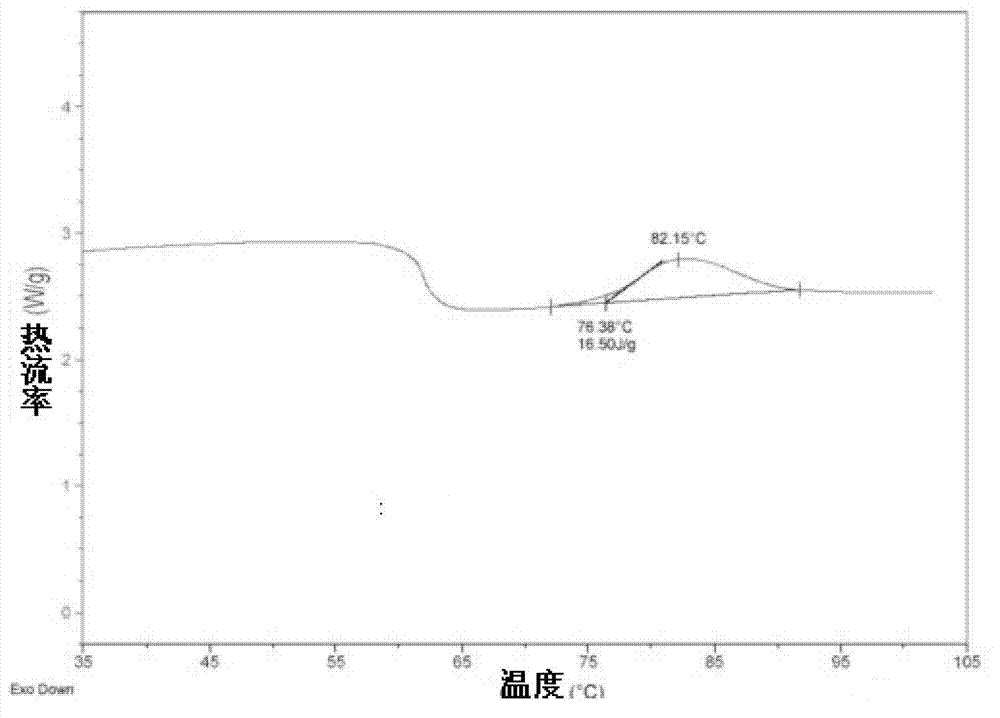

Embodiment 3

[0026] With embodiment 1, its difference is:

[0027] (1) After washing the skin and slicing the taro, soak it in the ammonia solution for 4 minutes, take it out and crush it, put the taro powder in the ammonia solution and continue soaking it for 4 hours, and pass through a 300-mesh sieve to get the filtrate;

[0028] (2) Dry the final centrifuged precipitate in an oven at 50°C to obtain rough dry starch. After crushing the rough dry starch, degrease with methanol with a volume fraction of 85% for 24 hours, then degrease with absolute ethanol for 8 hours, and place in Dry in an oven at 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Endothermic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com