(S)-pantoprazole sodium dihydrate and preparation method thereof

A technology for pantoprazole sodium and dihydrate, applied in the field of pharmaceutical synthesis, can solve the problems of large amount of non-polar crystallization solvent, unfavorable scale-up production, inability to complete crystallization, etc., achieves good appearance and color, and improves stability , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

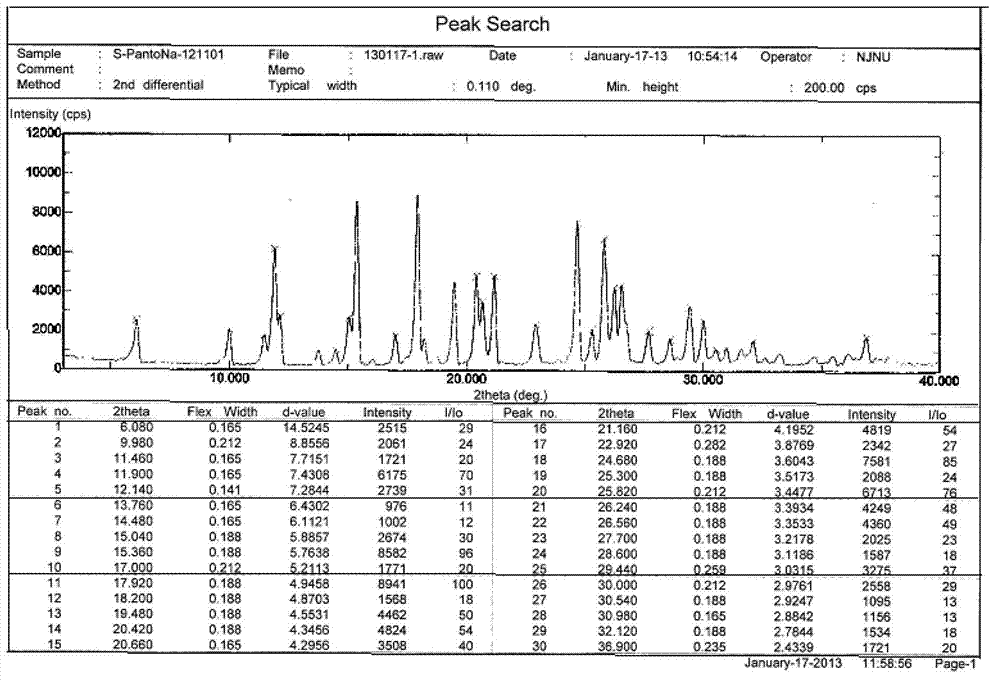

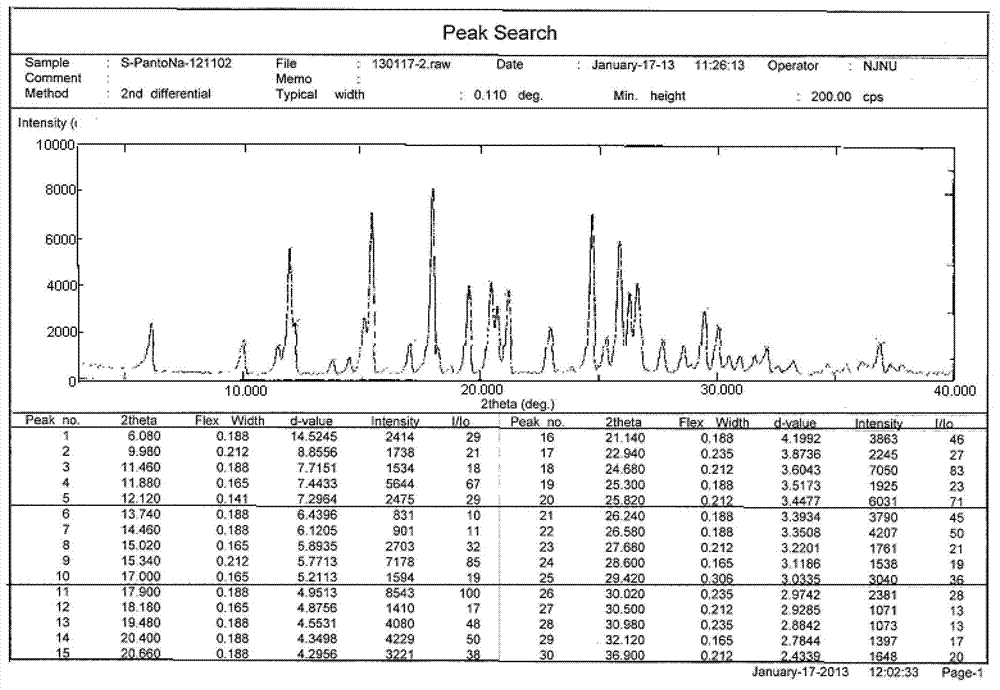

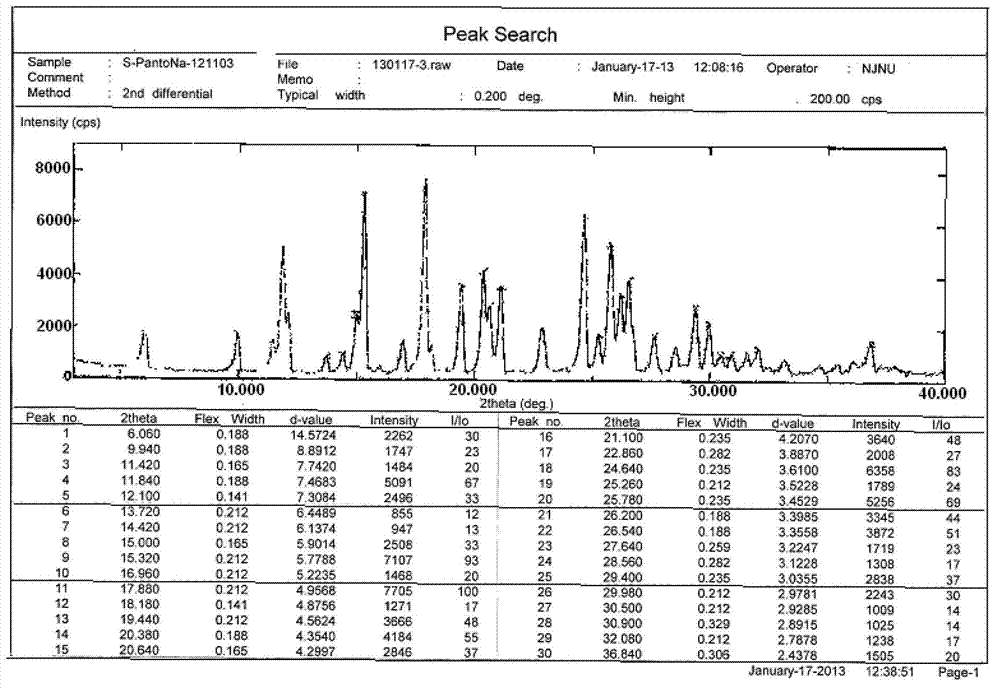

Image

Examples

Embodiment 1

[0050] Add 10g of highly enantioselective (S)-pantoprazole into a 250ml three-necked reaction flask, add 100ml of dichloromethane, dissolve completely under reflux, add activated carbon for decolorization for 30min, filter, and stir the filtrate at 20-30°C Add 10.0% by mass NaOH aqueous solution (prepared by NaOH and appropriate amount of purified water, the molar ratio of NaOH and (S)-pantoprazole is 1:1) to form salt and crystallize. =Stir and grow crystals at 0-10°C for 5 hours, filter, and vacuum-dry at 40-45°C for 6-8 hours to obtain 10.1 g of off-white (S)-pantoprazole sodium dihydrate, with a mass yield of 101.0%. Moisture: 8.9%, chemical purity: 99.82%, single impurity ≤ 0.1%; optical purity = 99.90%, dextrorotary body = 0.10%.

Embodiment 2

[0052] Add 10g of highly enantioselective (S)-pantoprazole into a 250ml three-necked reaction flask, add 100ml of dichloromethane, dissolve completely under reflux, add activated carbon for decolorization for 30min, filter, and stir the filtrate at 20-30°C Add 20.0% mass percentage of NaOH methanol solution (constituted by NaOH and appropriate amount of methanol, the molar ratio of NaOH and (S)-pantoprazole is 1.2:1) to form salt and crystallize, complete the addition within 10min, and put it in an ice-water bath T = Stir and grow the crystal at 0-10°C for 5 hours. Filtrate, and vacuum dry at 35-40°C for 6-8 hours to obtain 10.4 g of off-white (S)-pantoprazole sodium dihydrate, with a mass yield of 104.0%. Moisture: 8.8%, chemical purity: 99.85%, single impurity ≤ 0.1%; optical purity = 99.81%, dextrorotary body = 0.09%.

Embodiment 3

[0054] Add 10g of highly enantioselective (S)-pantoprazole into a 250ml three-necked reaction flask, add 100ml of dichloromethane, dissolve completely under reflux, add activated carbon for decolorization for 30min, filter, and stir the filtrate at 20-30°C Downstream add 10.0% mass percentage of CH 3 ONa methanolic solution (by CH 3 Configuration of ONa and appropriate amount of methanol, CH 3 The molar ratio of ONa and (S)-pantoprazole is 0.9:1) to form salt and crystallize. The addition is completed within 10 minutes, and the crystal is grown for 5 hours with stirring in an ice-water bath T=0-10°C. Filter and dry in vacuum at 20-25°C for 6-8 hours to obtain 10.1 g of off-white (S)-pantoprazole sodium dihydrate, with a mass yield of 101.0%. Moisture: 9.5%, chemical purity: 99.81%, single impurity ≤ 0.03%; optical purity = 99.84%, dextrorotary body = 0.16%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com