Normal hexane and benzene extractive distillation operating method

A technology of extractive distillation and extractive distillation column, which is applied in the field of n-hexane and benzene products, can solve the problems of unstable operation, low product purity, high energy consumption, etc., and achieve the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The mass composition of the mixture of n-hexane and benzene containing impurity components is as follows: n-hexane 38.6%, benzene 49.3%, methylcyclopentane 4.6%, cyclohexane 0.3%, n-heptane 1.4%, C7-C8 aromatics 3.5% %, unsaturated olefins 1.2%, other 1.1%.

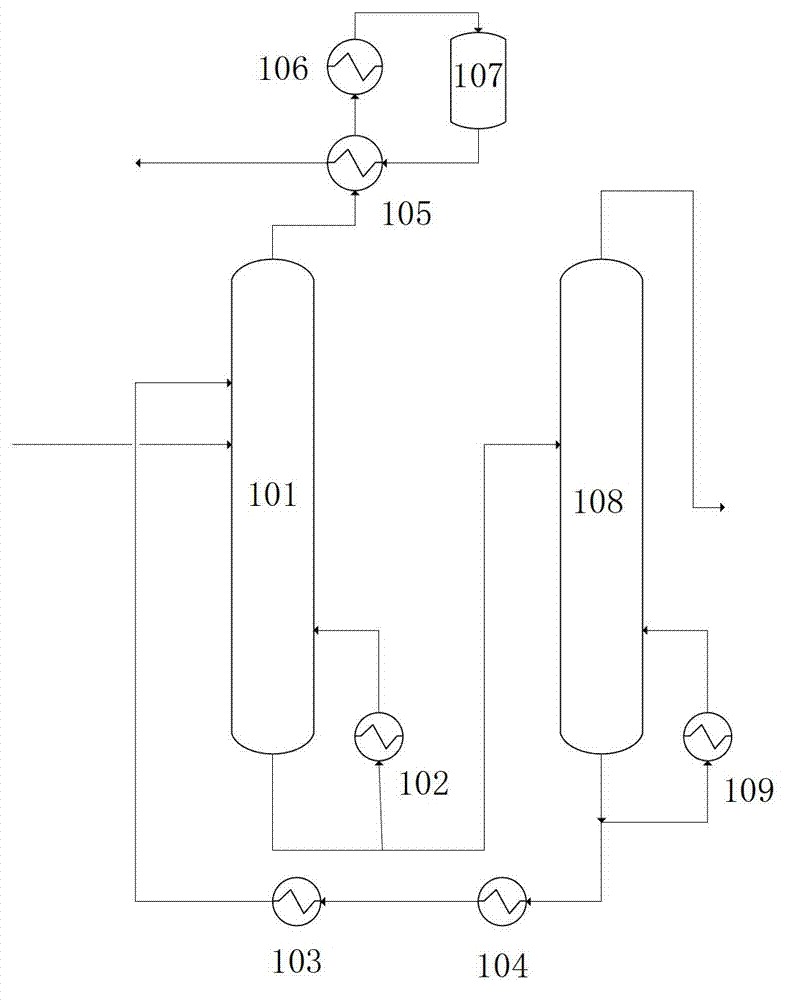

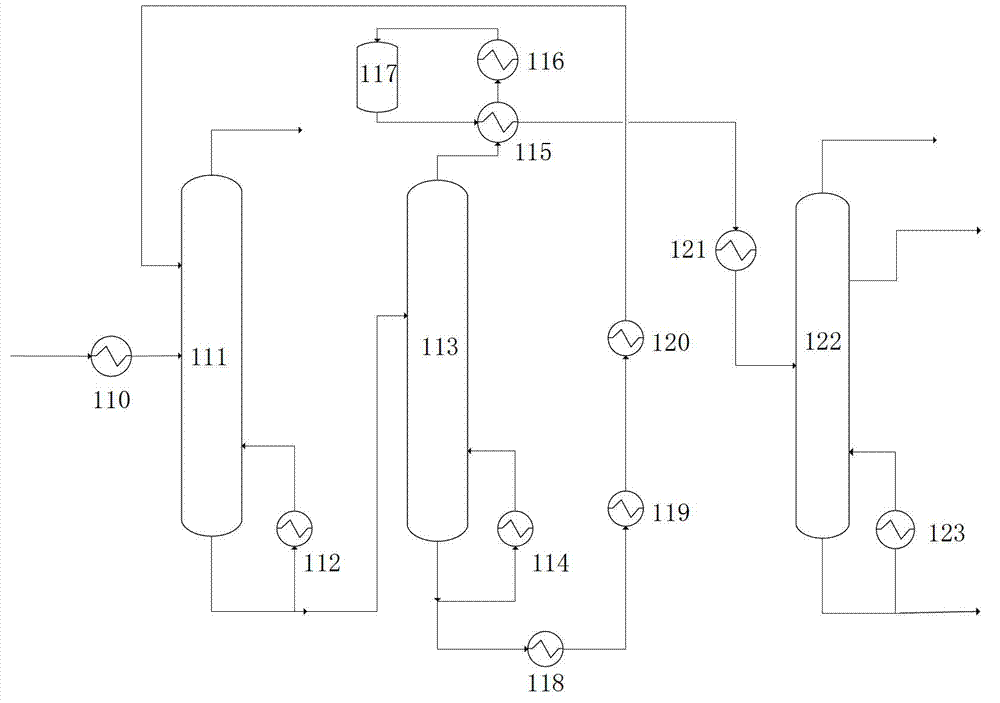

[0027]C3-C8 mixed hydrocarbon raw materials such as raffinate, pyrolysis gasoline or straight-run gasoline from the aromatics extraction unit, after removing components with a boiling point lower than n-hexane, the feed rate is 2100kg / h, and the temperature is 70-73 °C, enter the middle part of the n-hexane extractive distillation column 101 of the n-hexane extractive distillation separation and purification system, and the compounded extractant N-methylpyrrolidone 11500kg / hr enters the n-hexane extractive distillation column 101 from above the feed plate. The operating pressure of the n-hexane extracting and rectifying tower 101 is 1.2 bara, the temperature at the bottom of the tower is 115-118°C, and the temperat...

Embodiment 2

[0033] Raw material composition is with embodiment 1.

[0034] The feed rate of raw materials is 2100kg / h, the temperature is 70-73°C, and it enters the middle part of the n-hexane extractive distillation column 101 of the n-hexane extractive distillation separation and purification system, and the compound extractant N-formylmorpholine is 9500kg / hr from The upper part of the feed plate enters the n-hexane extractive distillation column 101. The operating pressure of the n-hexane extracting and rectifying tower 101 is 1.0 bara, the temperature at the bottom of the tower is 123-125°C, and the temperature at the top of the tower is 73-75°C. The n-hexane obtained from the top of the n-hexane extraction rectification tower 101 has a purity of 99.5%wt, and the benzene content is less than 100ppm. The benzene-rich extractant solution obtained from the bottom of the rectification tower 101 is sent to the first extractant recovery tower 108 to recover the extractant.

[0035] The be...

Embodiment 3

[0040] Raw material composition is with embodiment 1.

[0041] The raw material feed rate is 2100kg / h, the temperature is 70-73°C, and enters the middle part of 101 of the n-hexane extraction, rectification, separation and purification system, and the compound extraction agent N-methylpyrrolidone 10500kg / hr enters the n-hexane from above the feed plate Extractive distillation column 101. The operating pressure of the n-hexane extracting and rectifying tower 101 is 1.1 bara, the temperature at the bottom of the tower is 119-121°C, and the temperature at the top of the tower is 70-72°C. The n-hexane obtained from the top of the n-hexane extraction rectification tower 101 has a purity of 99.5%wt, and the benzene content is less than 100ppm. The benzene-rich extractant solution obtained from the bottom of the rectification tower 101 is sent to the first extractant recovery tower 108 to recover the extractant.

[0042] The benzene-rich extractant solvent from the bottom of n-hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com