Polyphenylene granular thermal-insulation mortar

A technology of polystyrene particles and thermal insulation mortar, which is applied in the field of building materials, can solve the problems of high cement consumption, unstable thermal insulation performance of thermal insulation mortar, and increase the manufacturing cost of thermal insulation mortar, and achieves low thermal conductivity, high softening coefficient and stable thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

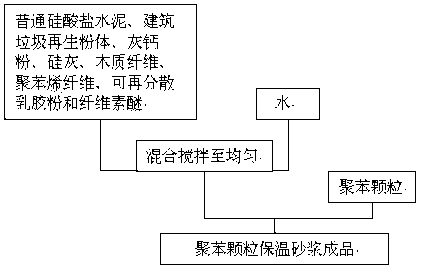

Method used

Image

Examples

Embodiment 1

[0043] Weigh 3350g of ordinary Portland cement, 500g of construction waste recycled brick powder, 750g of lime calcium powder, 250g of silica fume, 40L of polyphenylene particles, 80g of redispersible latex powder, 40g of cellulose ether, 35g of wood fiber, and 15g of polypropylene fiber , 4000g of water. Mix the dry mortar materials evenly, and then add water for stirring to obtain the finished polystyrene particle thermal insulation mortar.

[0044] The performance of the polystyrene particle insulation mortar of this embodiment is as follows:

[0045] ⑴Dry bulk density: 313kg / m 3 ; (2) Bulk density after soaking in water: 392kg / m 3 ; ⑶ water absorption: 0.25%; ⑷ compressive strength after softening: 0.27MPa; ⑸ 28d compressive strength: 0.30MPa; ⑹ softening coefficient: 0.91;

Embodiment 2

[0047] Weigh 3350g of ordinary Portland cement, 500g of construction waste recycled brick powder, 750g of lime calcium powder, 250g of silica fume, 40L of polyphenylene particles, 80g of redispersible latex powder, 40g of cellulose ether, 35g of wood fiber, and 15g of polypropylene fiber , 4000g of water. Mix the dry mortar materials evenly, then add water and stir to get the finished polyphenylene particle insulation mortar.

[0048] The performance of the polystyrene particle insulation mortar of this embodiment is as follows:

[0049] ⑴Dry bulk density: 270kg / m 3 ; (2) Bulk density after soaking in water: 336kg / m 3 ; ⑶ water absorption: 0.24%; ⑷ compressive strength after softening: 0.19MPa; ⑸ 28d compressive strength: 0.28MPa; ⑹ softening coefficient: 0.67;

Embodiment 3

[0051] Weigh 3350g of ordinary Portland cement, 250g of recycled concrete powder from construction waste, 1000g of lime calcium powder, 250g of silica fume, 40L of polyphenylene particles, 80g of redispersible latex powder, 40g of cellulose ether, 35g of wood fiber, and 15g of polypropylene fiber , 4000g of water. Mix the dry mortar materials evenly, then add water and stir to get the finished polyphenylene particle insulation mortar.

[0052] The performance of the polystyrene particle insulation mortar of this embodiment is as follows:

[0053] ⑴Dry bulk density: 239kg / m 3 ; (2) Bulk density after soaking in water: 306kg / m 3 ; ⑶ water absorption: 0.28%; ⑷ compressive strength after softening: 0.21MPa; ⑸ 28d compressive strength: 0.22MPa; ⑹ softening coefficient: 0.97;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry unit weight | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com