New-energy electric vehicle traction motor rotor de-weight machine

A technology of electric vehicles and traction motors, applied in metal processing machinery parts, measuring/indicating equipment, drilling/drilling equipment, etc., can solve the problem of slow transmission of dynamic information, achieve fast, accurate and convenient operation, maintain consistency, The effect of deduplicating information in one step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

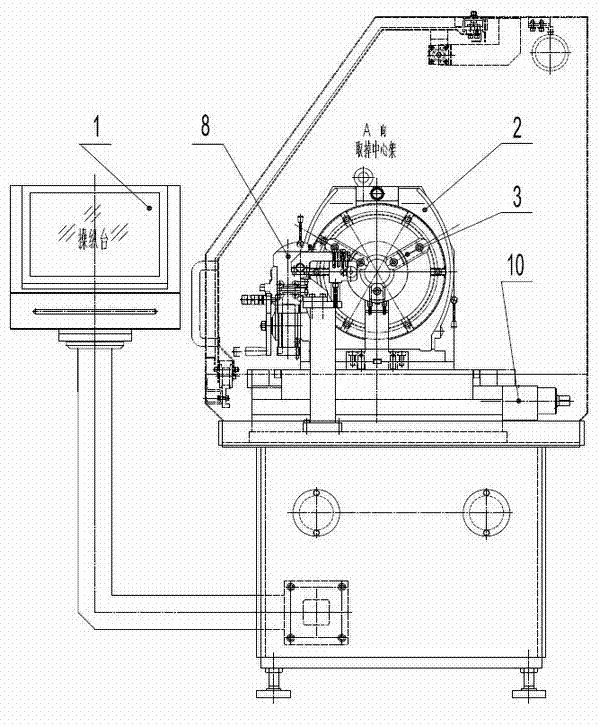

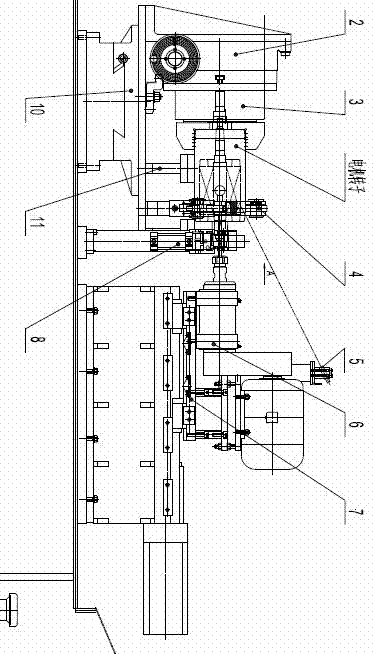

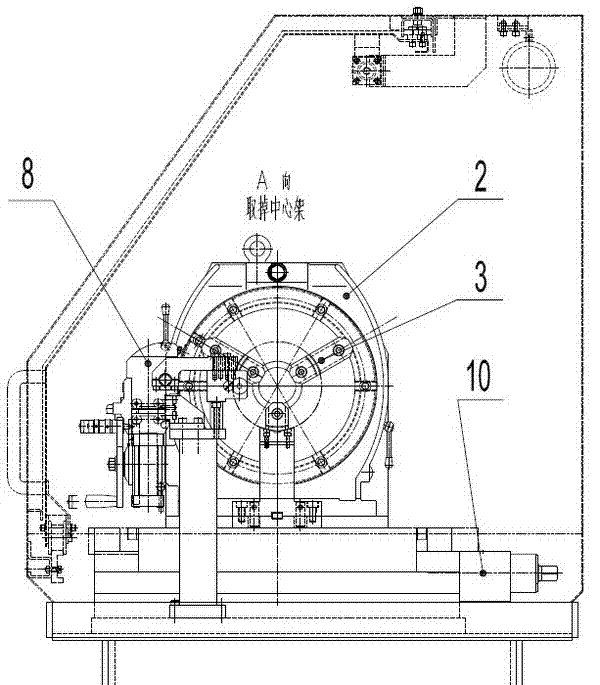

[0029] In order to further understand the energy electric vehicle traction motor rotor de-weighting machine, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] It adopts laser alignment, indexing plate indexing, drilling processing to remove the weight of the rotor, including console and display screen 1, vertical rotary table 2, three-jaw self-centering non-standard chuck 3, center frame 4. Laser instrument calibrator 5. Drilling spindle box 6. Servo slide table 7. Mobile drill sleeve 8. Industrial vacuum cleaner 9. Traversing slide table 10. Auxiliary support 11. Limit block 12. Vertical rotary table 2, three-jaw self-centering chuck 3, center frame 4, coaxial arrangement, the center line of the traverse slide table 10 and the center line of the servo slide table 7 are perpendicular to each other, the center line of the drilling headstock 6 and the servo slide table The center lines of tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com