Slurry management device for wire saw

A technology for managing devices and slurry, applied in fine working devices, grinding/polishing safety devices, stone processing equipment, etc., can solve problems such as difficult management and achieve stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

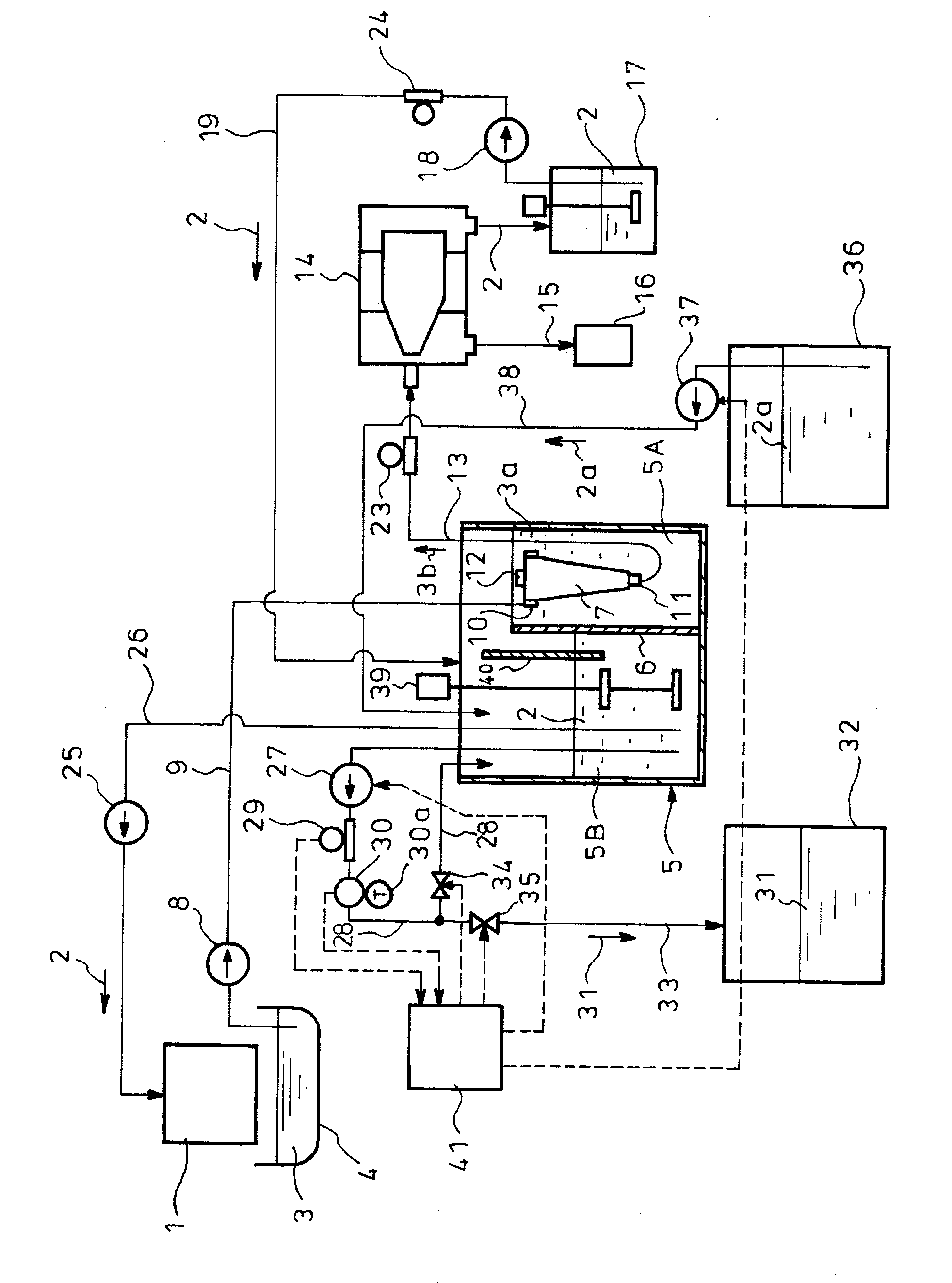

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0043] figure 1 It is a block diagram showing an embodiment of the slurry management device of the wire saw according to the present invention. In the figure, 1 is a fixed abrasive wire saw. In the fixed abrasive wire saw 1, a slurry 2 composed of a coolant is supplied, Cutting of the ingot passing through the fixed abrasive wire not shown is performed, and the slurry waste liquid 3 discharged from the fixed abrasive wire saw 1 is received by the liquid receiving container 4 .

[0044] In the figure, 5 is a storage tank, and the storage tank 5 is formed with a first tank 5A and a second tank 5B separated by an overflow wall 6 provided inside, and a cyclone with a tapered shape toward the lower side is provided in the first tank 5A. Separator 7.

[0045] The slurry waste liquid 3 in the liquid receiving container 4 is supplied to the cyclone separator 7 provided in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com