High-power non-contact type rapid laser heating device

A non-contact, rapid heating technology, applied in the preparation of test samples, etc., can solve the problems of low heating rate, thermal shock, ablation test, high construction and operation costs, and achieve low cost and linearly adjustable output power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

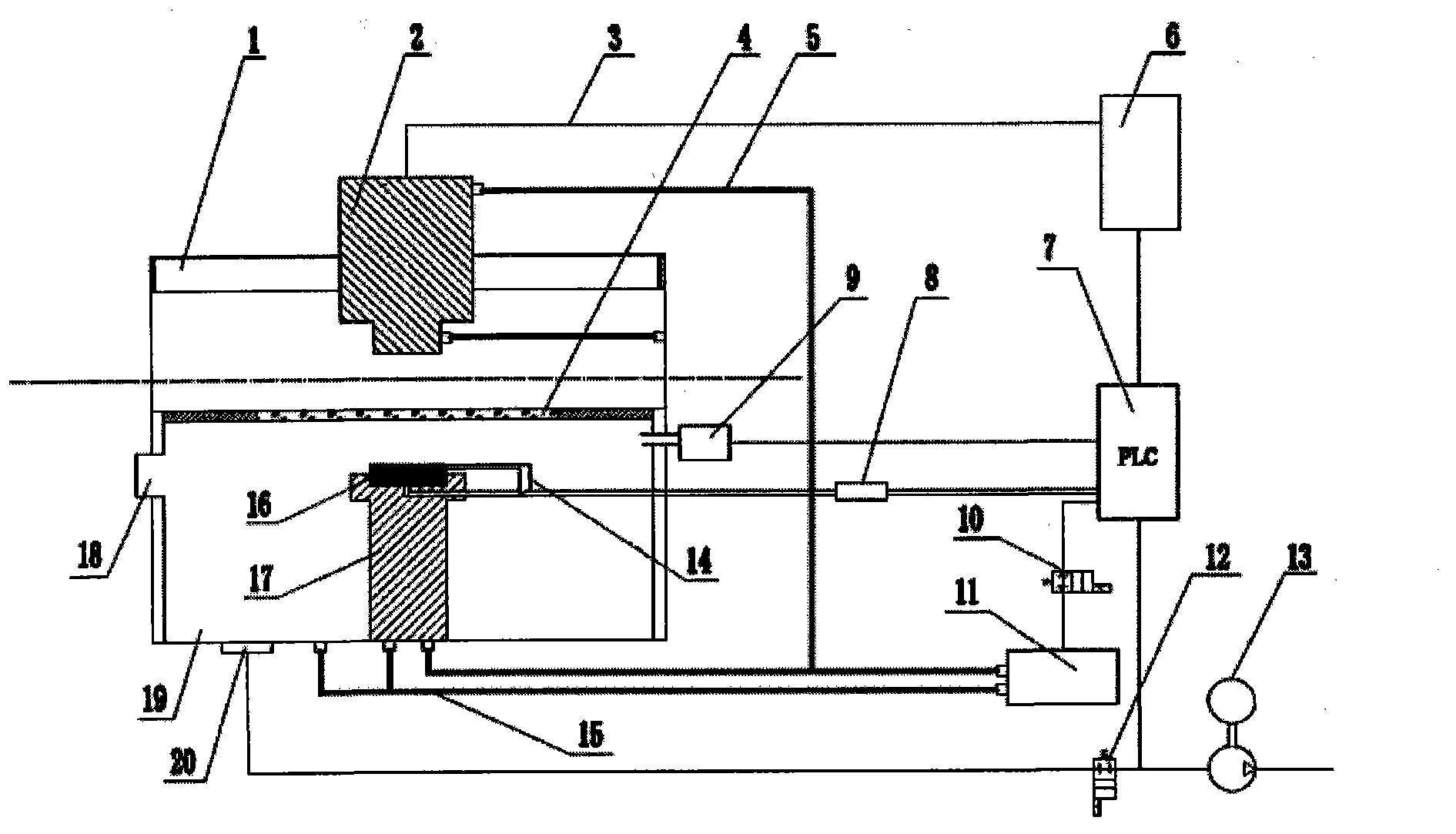

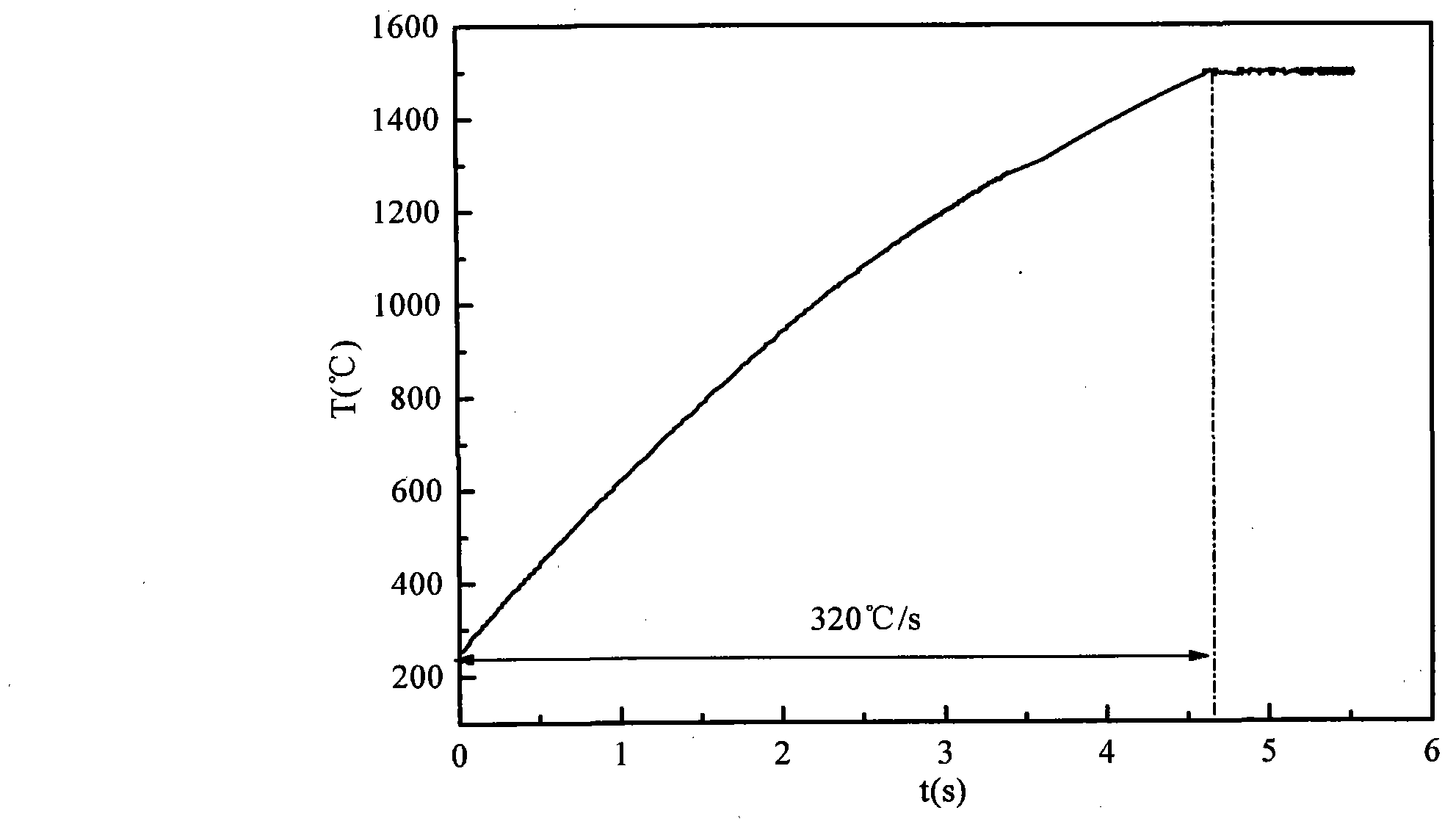

Embodiment 1

[0024] This embodiment is a high-power non-contact laser rapid heating device, including a semiconductor laser 6, the laser energy is coupled into the optical fiber 3, the output end of the optical fiber 3 is connected to the lens 2, and the lens 2 is fixed on the adjustment bracket 1, by changing the bracket 1 The position and the focal length of the lens 2 adjust the heating area, the laser beam passes through the optical fiber 3 and the lens 2, and converges on the sample 16 through the CaF2 window above the environmental chamber 19, and the sample is placed on the water-cooling bracket 17, and the first cooling circulating water pipe 5 are respectively connected to the lens 2, the water-cooling bracket 17 and the refrigerator 11, and the second cold water circulation pipe 15 is respectively connected to the water-cooling bracket 17, the environmental chamber 19 and the refrigerator 11, and is controlled by the PLC control subsystem 7, and the thermocouple probe 14 is placed...

Embodiment 2

[0028] This embodiment is a high-power non-contact laser rapid heating device, including a semiconductor laser 6, the laser energy is coupled into the optical fiber 3, the output end of the optical fiber 3 is connected to the lens 2, and the lens 2 is fixed on the adjustment bracket 1, by changing the bracket 1 The position and the focal length of the lens 2 adjust the heating area, the laser beam passes through the optical fiber 3 and the lens 2, and converges on the sample 16 through the CaF2 window above the environmental chamber 19, and the sample is placed on the water-cooling bracket 17, and the first cooling circulating water pipe 5 are respectively connected to the lens 2, the water-cooling bracket 17 and the refrigerator 11, and the second cold water circulation pipe 15 is respectively connected to the water-cooling bracket 17, the environmental chamber 19 and the refrigerator 11, and is controlled by the PLC control subsystem 7, and the thermocouple probe 14 is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com