Hot air supply system for belt type roasting machine

A technology of belt roaster and hot air supply, which is applied in the direction of lighting and heating equipment, furnace types, furnaces, etc., and can solve the problem that the belt roaster has not been greatly developed, the amount of high-temperature-resistant special alloy steel is large, and the quality of finished pellets Inhomogeneity and other problems, to achieve the effect of saving production and maintenance costs, stable equipment operation, economical and practical pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

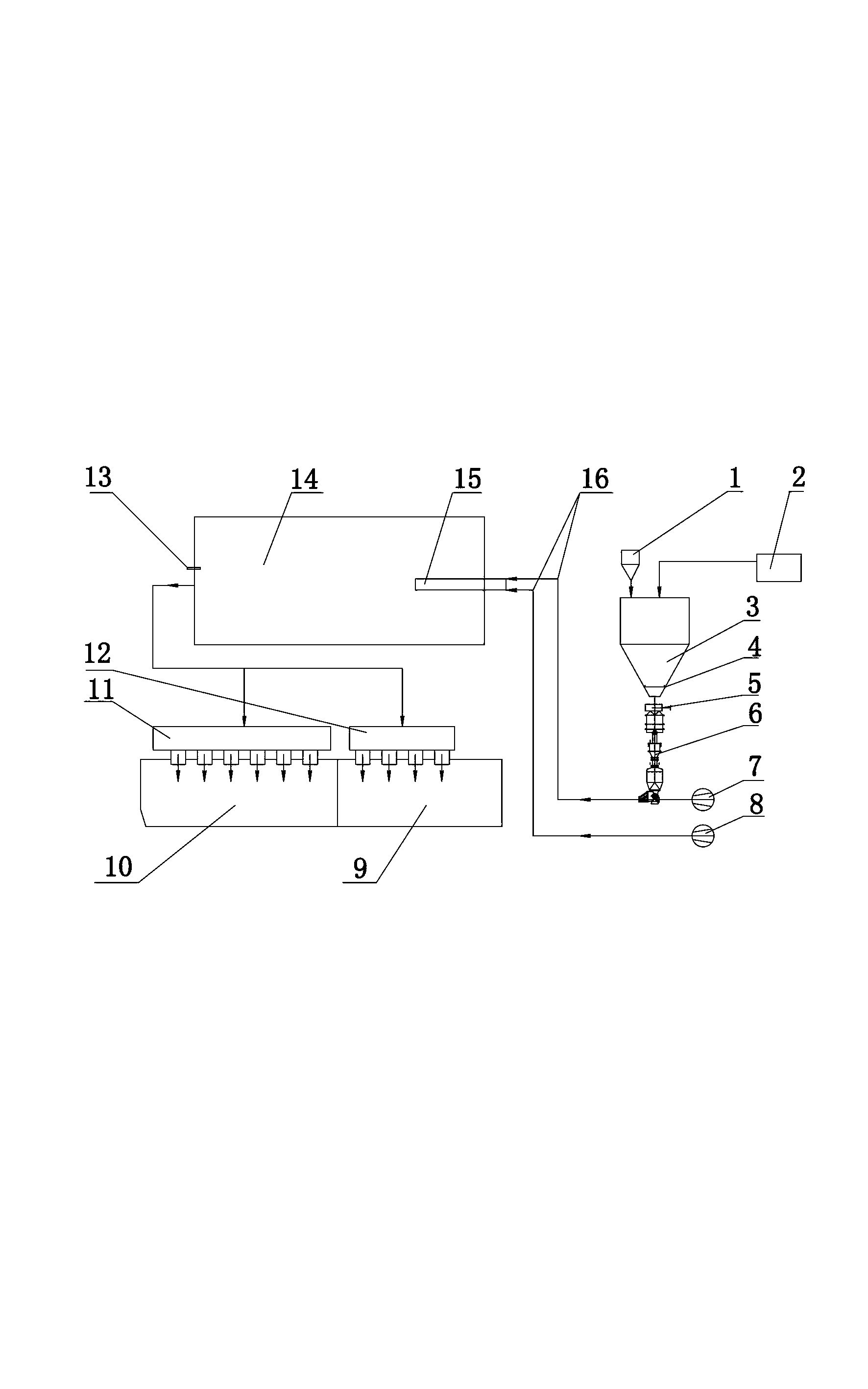

[0015] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a kind of belt roaster hot air supply system of the present invention comprises the upper cover 10 of the roasting section of the belt roaster and the upper cover 9 of the soaking section of the belt roaster, and is characterized in that it is roasted in the belt roaster One side of the section upper cover 10 and the belt roaster soaking section upper cover 9 is provided with a pulverized coal bin 3, and the top of the pulverized coal bin 3 is provided with a pulverized coal pneumatic conveying device 2 and a dust removal device 1, and the pulverized coal bin 3 The bottom outlet is equipped with an anti-blocking material safety protection device 4, a valve body 5 and a pulverized coal metering scale 6, and the pulverized coal metering scale 6 is connected to a coal-injected Roots blower 7, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com