High-frequency vibrating hammering stone crusher

A high-frequency vibration and rock crusher technology, which is applied in earth movers/shovels, construction, etc., can solve problems such as sticking, easy-to-produce failures, and no sealing structure, so as to achieve high crushing efficiency, reduce operating costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

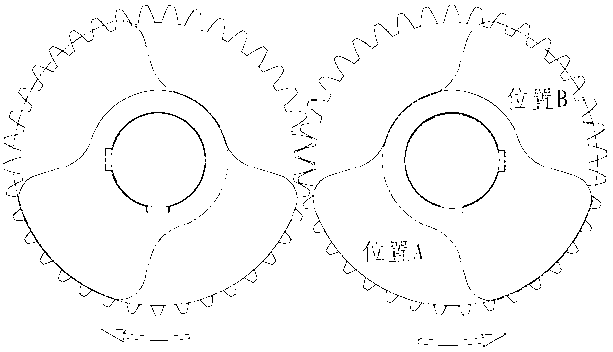

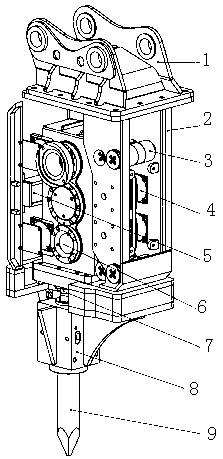

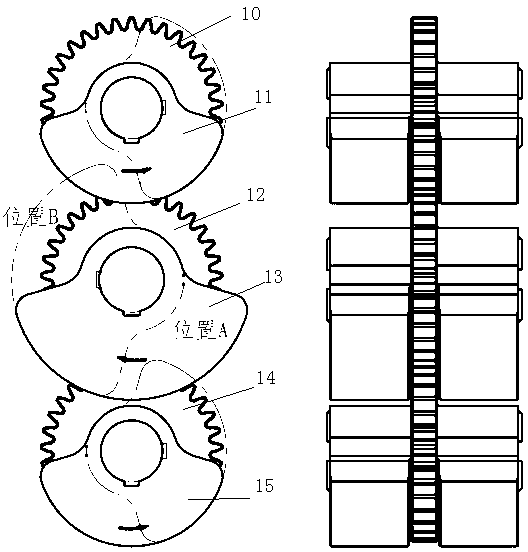

[0015] Depend on figure 2 , image 3 As shown, a high-frequency vibration hammer crusher includes a shell 2, an excavator connector 1, a vibrating body 6, a hammer 7, a steel drill retainer 8, a steel drill 9, a connecting column 3, a limiter The bit box 5 and the hydraulic motor, the upper part of the housing 2 are connected with the excavator connector 1, and the characteristics are that the lower part of the housing 2 is equipped with a steel drill holder 8 and a steel drill 9, and the main body of the vibrating body 6 is An inner box is placed in the housing 2, the vibrating body 6 is connected with the housing 2 in the form of four rods, and is connected with the vibration damping pad 4 to maintain the relative position, and the vertical axis of the vibrating body 6 is provided with a single row of three eccentric wheels or Double rows of six eccentric wheels, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com