Corrosion method for germanium substrate sheet of solar battery

A technology for solar cells and negatives, applied in circuits, electrical components, climate sustainability, etc., can solve the problems of easily broken pieces and low strength of germanium sheets, and achieve the effects of short operation time, reliable quality and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: take the example of corroding 4 inches of germanium sheet, its etching method comprises the following steps:

[0025] (1) Measure 1200:ml of pure water and pour it into the corrosion tank, then measure 140ml of hydrofluoric acid with a mass concentration of 48% and pour it into the corrosion tank to form No. 1 corrosion liquid;

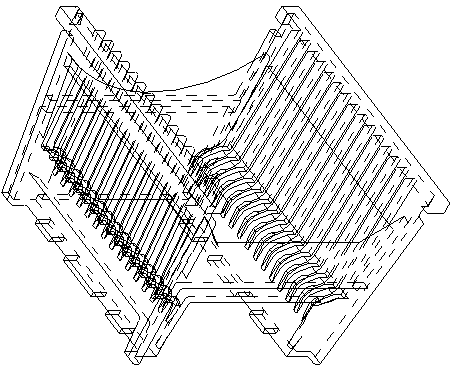

[0026] (2) Insert the ground germanium slices into the plug in parallel order (such as figure 1 As shown in ), place 10 pieces for each plug, rinse with pure water, immerse the plug horizontally in No. Plug, after corroding the germanium sheet for 7 seconds, take it out;

[0027] (3) Quickly put the removed jam into the pure water tank and push it back and forth for cleaning, then rinse it with pure water, take out one of the germanium sheets to measure its thickness, and check whether the corrosion loss requirement is met, and the corrosion loss is required to be 3 ~5μm; the service life of No. 1 corrosion solution is guarantee...

Embodiment 2

[0032] Embodiment 2: take the example of corroding 6 inches of germanium sheet, its etching method comprises the following steps:

[0033] (1) Measure 1250:ml of pure water and pour it into the corrosion tank, then measure 146ml of hydrofluoric acid with a mass concentration of 49% and pour it into the corrosion tank to form No. 1 corrosion liquid;

[0034] (2) Insert the ground germanium slices into the plug in parallel order (such as figure 1 As shown), place 15 pieces of each plug, rinse with pure water, immerse the plug horizontally in No. 1 corrosion solution to ensure that the germanium sheet is completely submerged, and shake the plug back and forth in a direction parallel to the surface of the germanium sheet , after corroding the germanium sheet for 8 seconds, take it out;

[0035] (3) Quickly put the removed jam into the pure water tank and push it back and forth for cleaning, then rinse it with pure water, take out one of the germanium sheets to measure its thickne...

Embodiment 3

[0040]Embodiment 3: take the example of corroding 8 inches of germanium sheet, its etching method comprises the following steps:

[0041] (1) Measure 1300:ml of pure water and pour it into the corrosion tank, then measure 150ml of hydrofluoric acid with a mass concentration of 50% and pour it into the corrosion tank to form No. 1 corrosion solution;

[0042] (2) Insert the ground germanium slices into the plug in parallel order (such as figure 1 As shown), place 20 pieces of each plug, rinse with pure water, immerse the plug horizontally in No. 1 corrosion solution to ensure that the germanium sheet is completely submerged, and shake the plug back and forth in a direction parallel to the surface of the germanium sheet , after corroding the germanium sheet for 10 seconds, take it out;

[0043] (3) Quickly put the removed jam into the pure water tank and push it back and forth for cleaning, then rinse it with pure water, take out one of the germanium sheets to measure its thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com