Powder metallurgy high-toughness cold-work mould steel and preparation method thereof

A cold work die steel and powder metallurgy technology, applied in the field of iron-based alloys, can solve the problem of high production cost, achieve the effects of fine MC carbide, uniform steel structure, and improved nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

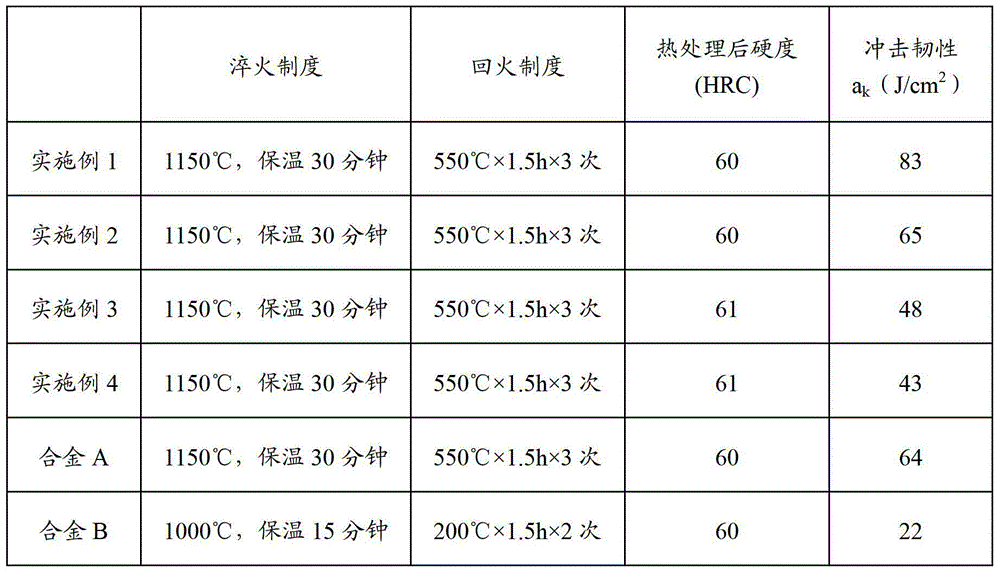

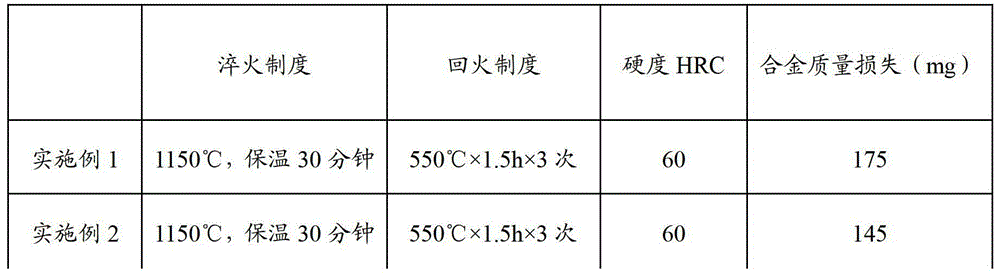

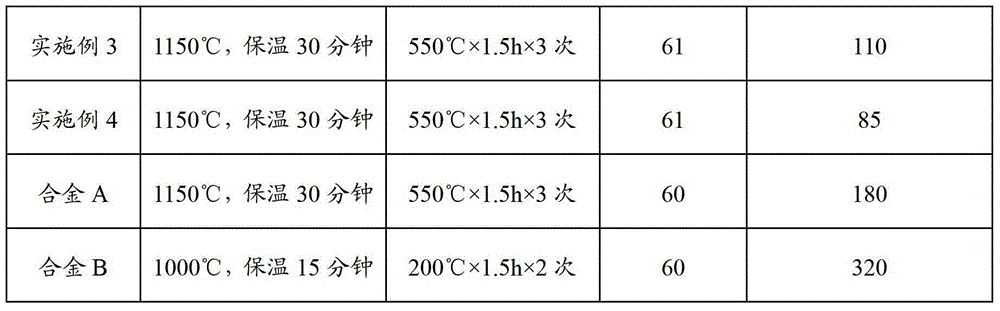

Examples

Embodiment Construction

[0034] In the following, the cold work die steel of the present invention and its preparation method will be further explained in detail in combination with examples. In this specification, the content of alloying elements in steel is expressed in mass percentage, unless otherwise specified.

[0035] In the cold work die steel of the present invention, a certain amount of element Nb is added together with a certain amount of element V. As mentioned above, the function of Nb is to reduce the nucleation barrier of MC carbides and promote the formation of finer MC carbides, thereby improving the toughness of the steel of the present invention.

[0036] In order to achieve satisfactory overall performance, each alloy composition in the steel of the present invention should be controlled within the range given above, and the function of each alloy element in the present invention will be described in detail below.

[0037] C: C is one of the constituent elements of MC carbide, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com