Modified MC nylon

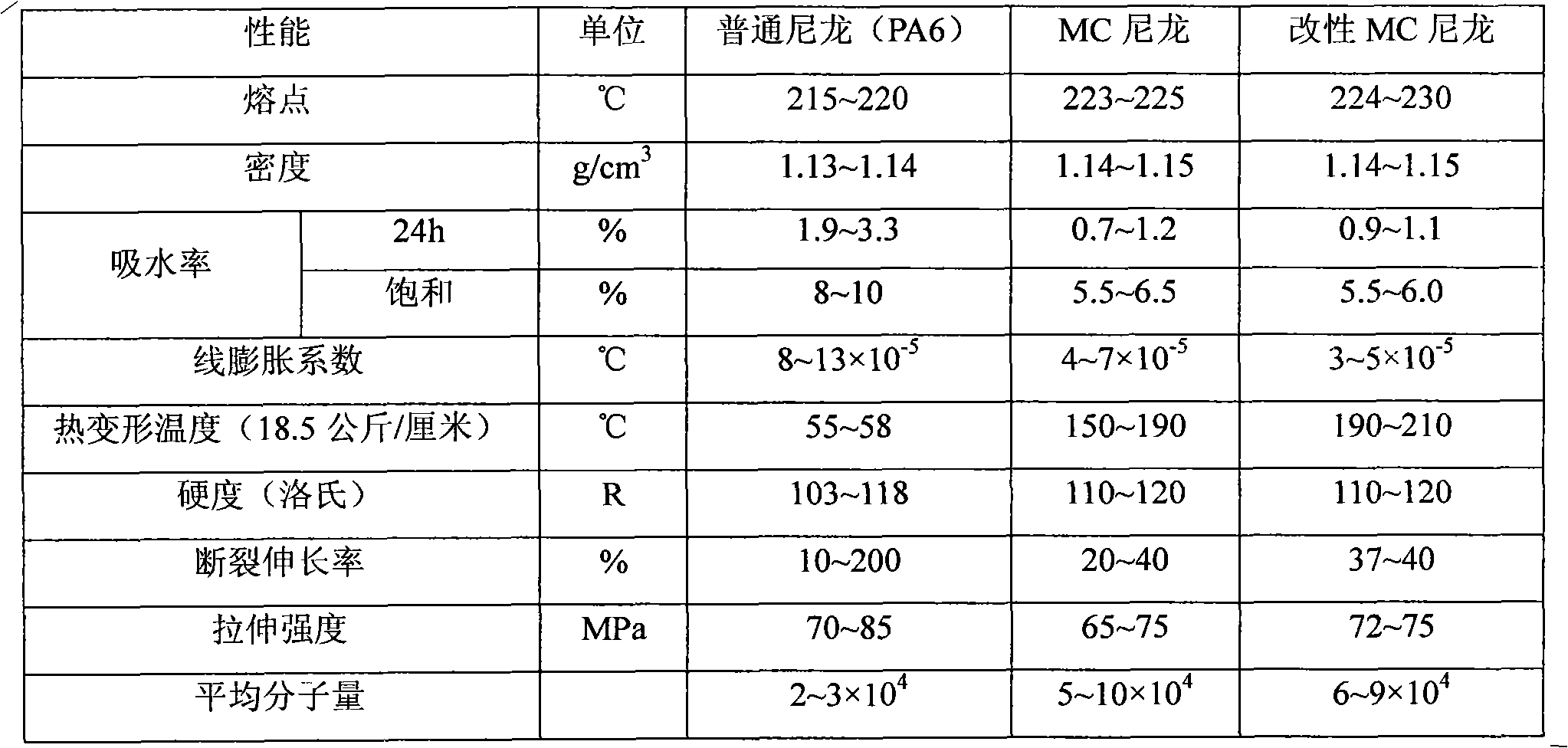

A modified nylon technology, which is applied in the field of polymer synthesis and modified processing, can solve the problems of unstable elongation at break, large linear expansion coefficient, and low impact strength, and achieve less monomer content, small friction coefficient, The effect of high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

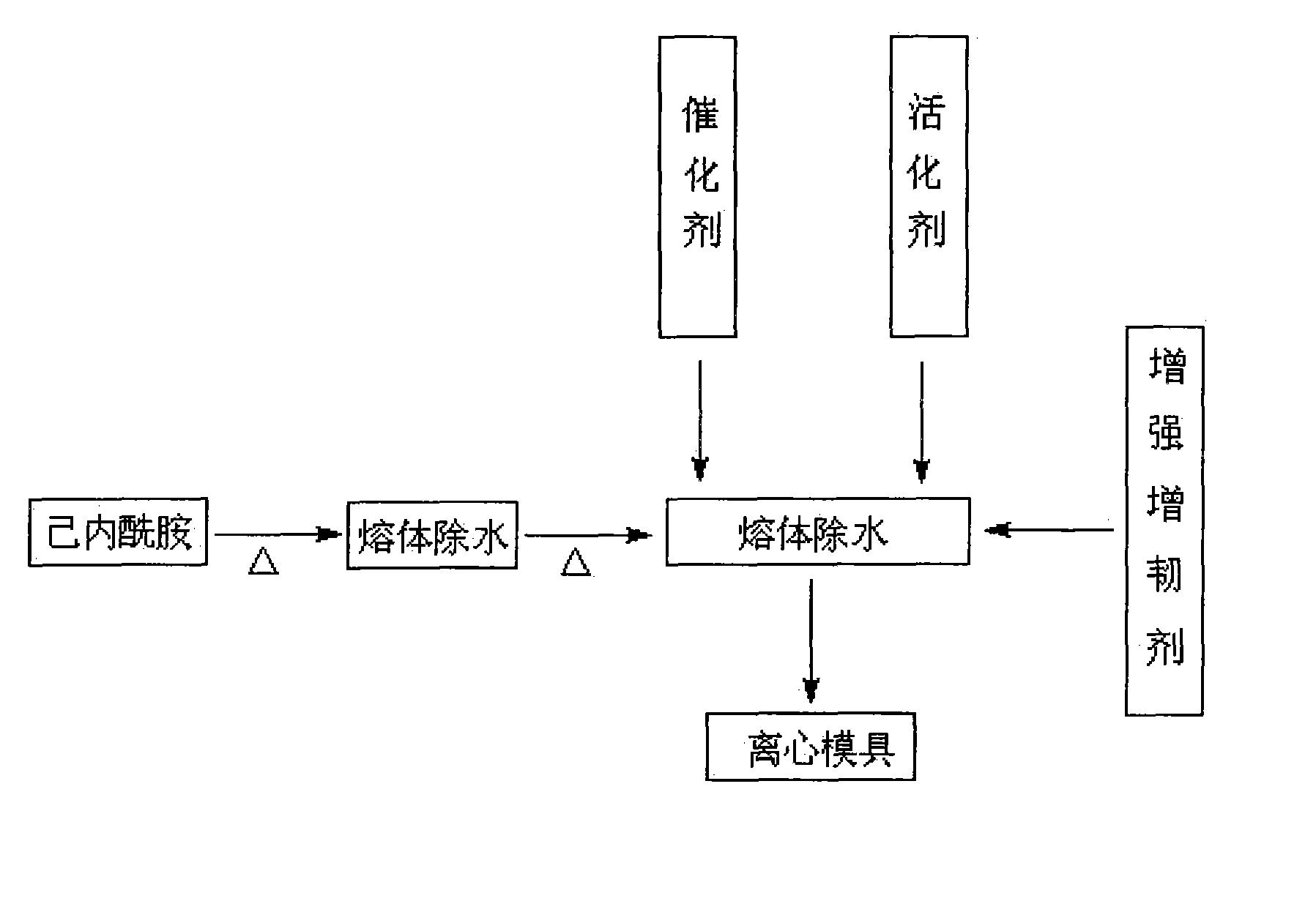

Method used

Image

Examples

specific Embodiment approach 1

[0016] Melt 100g of caprolactam at 130°C completely, distill off the water under reduced pressure, add 0.2g of NaOH, 0.6g of triamine methylphosphate and N-benzoyl caprolactam, and 10g of montmorillonite and 5g of liquid polybutylene to the system ethylene, injected into the mold for rapid polymerization molding. Then use the method of thermal demoulding, heat treatment in transformer oil at 150 ℃ to relieve stress, the time is about 15min / mm thickness, and the casting is cooled slowly after the heat treatment.

specific Embodiment approach 2

[0017] Melt 100g caprolactam completely at 110°C, distill off moisture under reduced pressure, add 0.1g sodium hydride, 0.8g methyl phosphate triamine and acetyl caprolactam, 6g fly ash, 4g attapulgite and 7g poly Ethylene oxide, injected into the mold for rapid polymerization. Then use the method of thermal demoulding, heat treatment in transformer oil at 130°C to relieve stress, the time is about 30min / mm thickness, and the casting is cooled slowly after the heat treatment.

specific Embodiment approach 3

[0018] Melt 100g caprolactam completely at 150°C, distill off water under reduced pressure, add 0.3g sodium methoxide, 1.0g diphenylmethane diisocyanate and 3g kaolin, 5g mica, 4g polyurethane to the system, and inject it into the mold for rapid polymerization forming. Then use the method of thermal demoulding, heat treatment in transformer oil at 160°C to relieve stress, the time is about 20min / mm thickness, and the casting is cooled slowly after the heat treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com