Novel gear honing processing method

A processing method and technology of gear honing, which is applied in the field of ultra-precision machining, can solve the problems of short honing wheel accuracy maintenance time, high price of internal gear honing equipment, and inability to improve tooth profile accuracy, so as to achieve long accuracy maintenance time and honing Good performance and the effect of reducing gear noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described below in conjunction with concrete processing example:

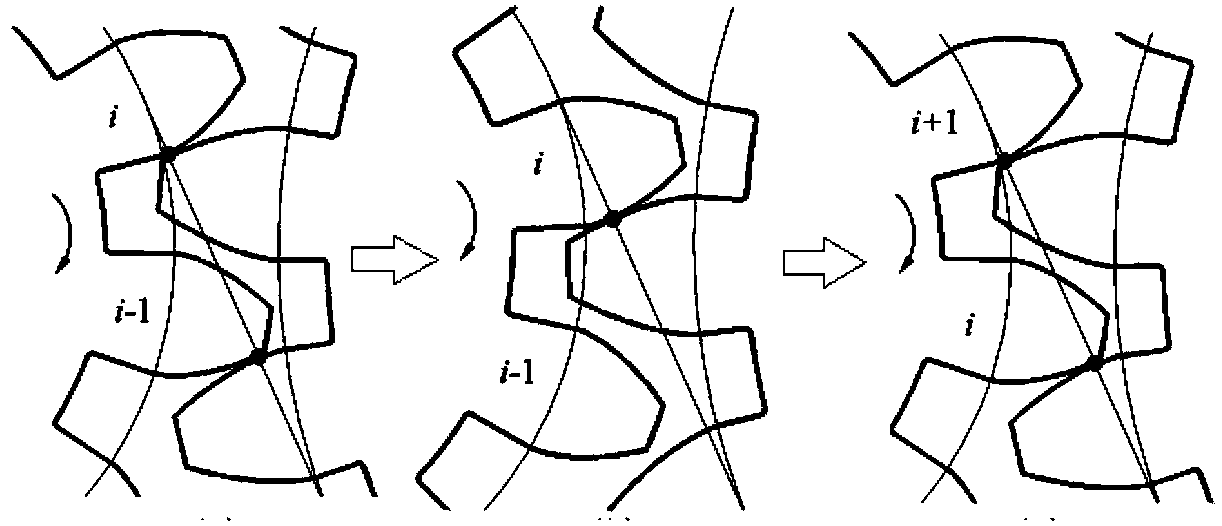

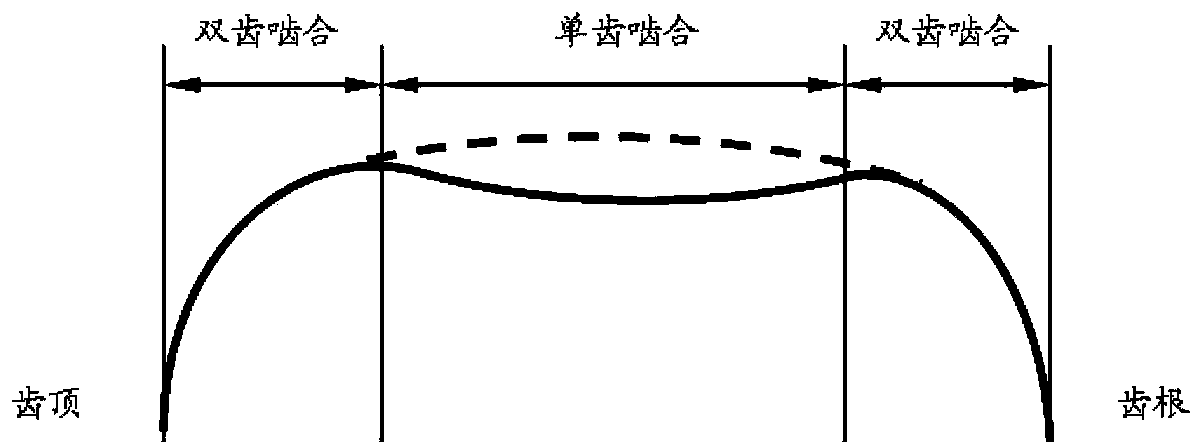

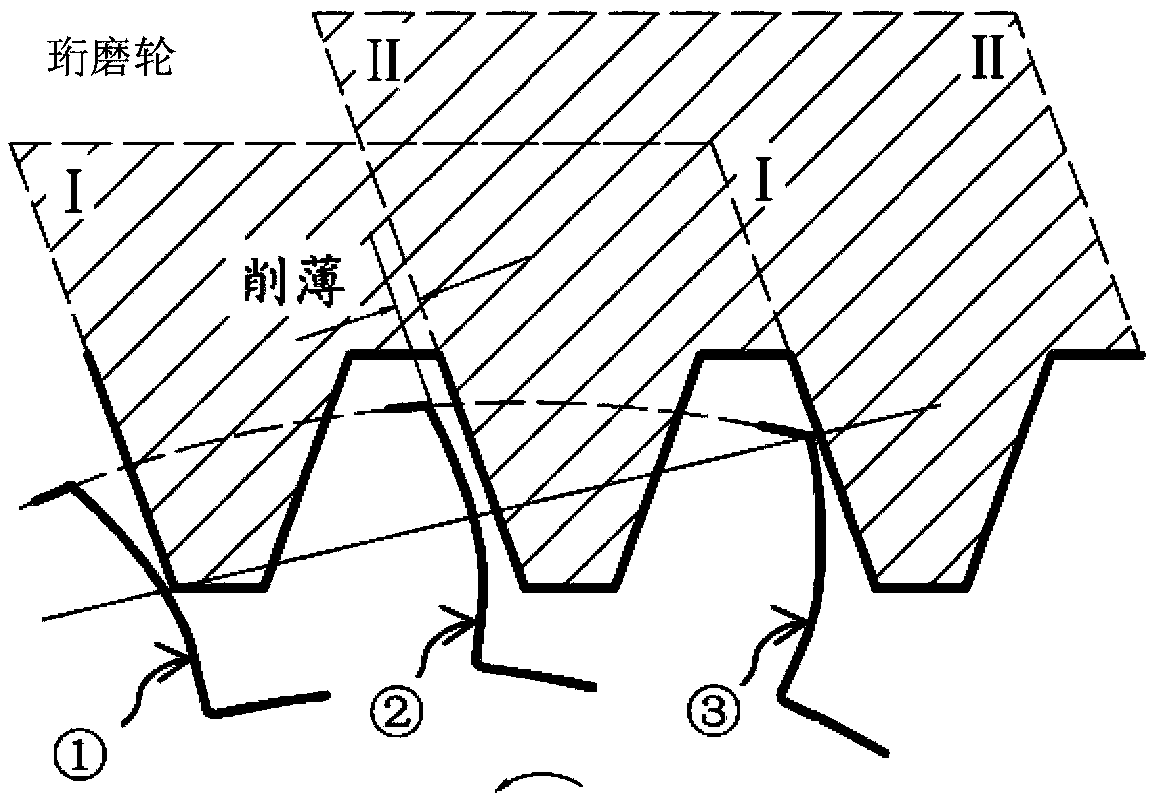

[0037] First of all, it is necessary to select the honing wheel according to the parameters of the gear to be machined. It adopts a special honing wheel. During the honing process, the axial tooth shape of the honing wheel is the same as that of the rack. The honing wheel and the gear to be machined rotate at the same time. The odd-numbered tooth surface I is thinned, the even-numbered tooth surface II is ground down, and the honing process is all completed by the odd-numbered tooth surface I of the honing wheel. The thinning amount is:

[0038] b = ( z 1 × tan α + h a 2 + ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com