high pressure water pump

A high-pressure water pump and housing technology, applied in the direction of pumps, pump components, pump devices, etc., can solve problems such as piston wear, piston damage, and unstable spray pressure, so as to avoid accumulation, improve service life, and avoid alternate changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

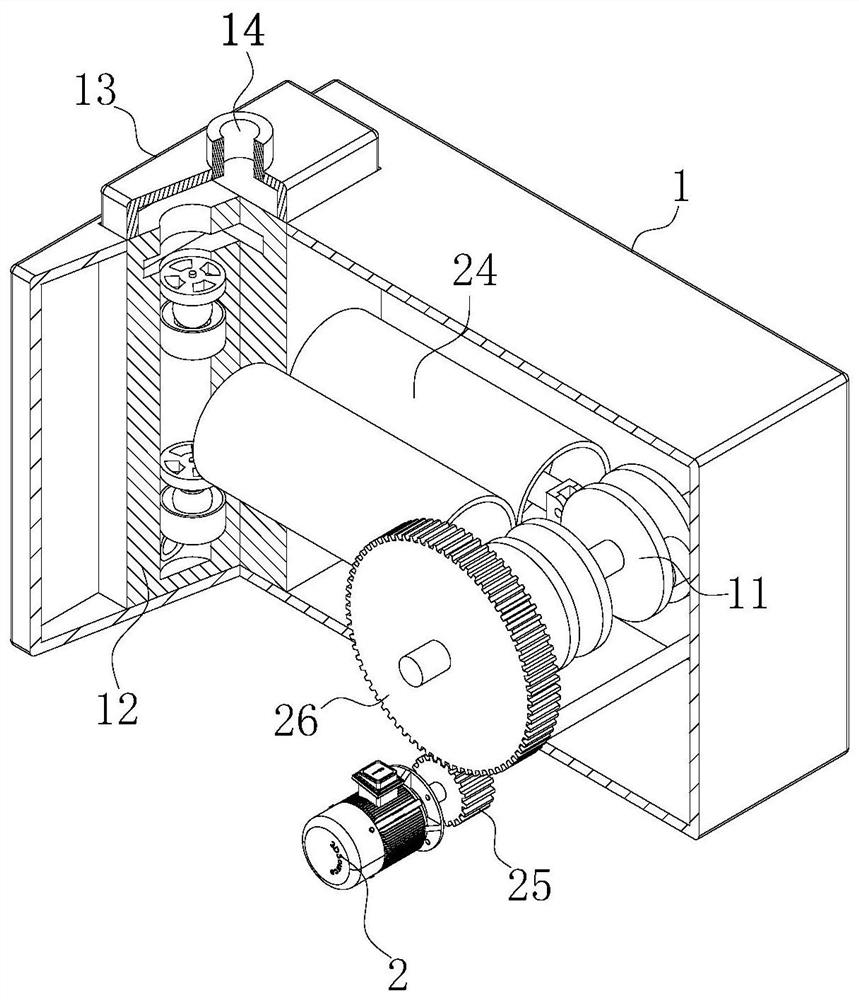

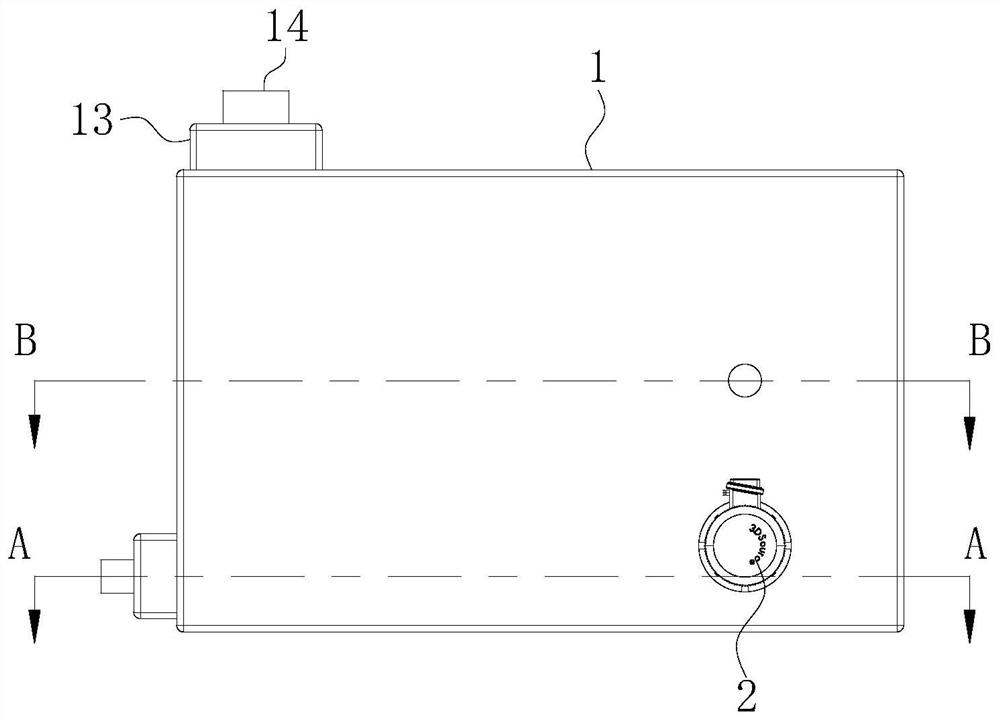

[0028] As an embodiment of the present invention, the front and rear side walls of the housing 1 are jointly rotatably connected with a rotating column directly below the crankshaft 11; the outer arc surface of the rotating column is close to the front wall of the housing 1 The first gear 25 is fixedly connected; the front end surface of the housing 1 is fixedly connected with the motor 2 at the position of the rotating column, and the output shaft of the motor 2 is fixedly connected with the rotating column; the outer arc surface of the crankshaft 11 is fixedly connected with Second gear 26, meshing connection between the second gear 26 and the first gear 25, and the diameter size of the second gear 26 is greater than the diameter size of the first gear 25; during work, by setting the first gear 25 and the second gear 26 , the motor 2 drives the first gear 25 to rotate, the first gear 25 drives the second gear 26 to rotate through the meshing mode, the rotation of the cranksha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com