Water tank assembly for irrigating needle online cleaning and sterilizing

A technology for filling needles and water tanks, applied in the fields of medical packaging machinery and food, can solve the problems of increasing the risk of sterility assurance, increasing the activities of operators, and difficult to ensure manual operations, and reducing the risk of contamination and cross-contamination, Low cost, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

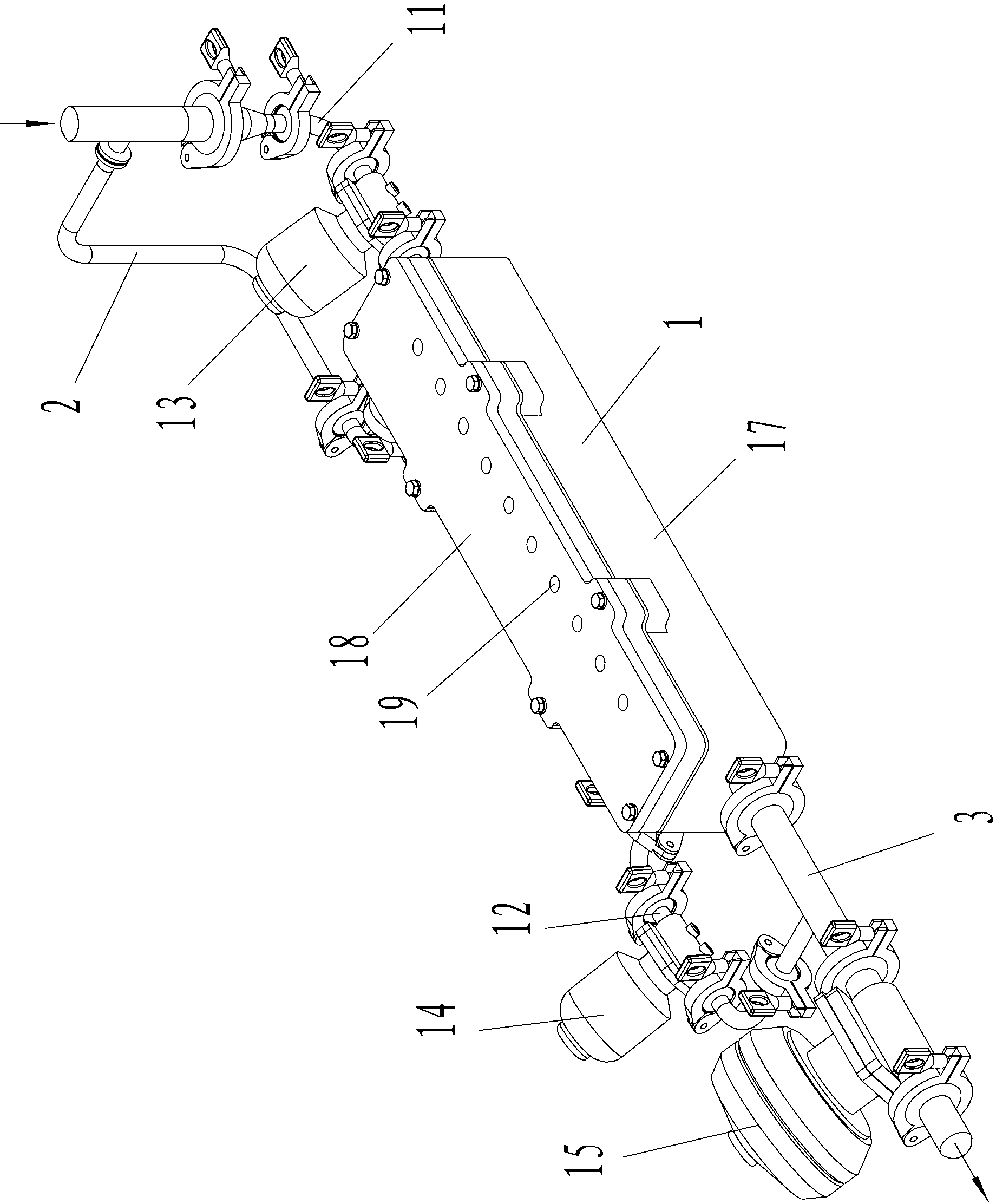

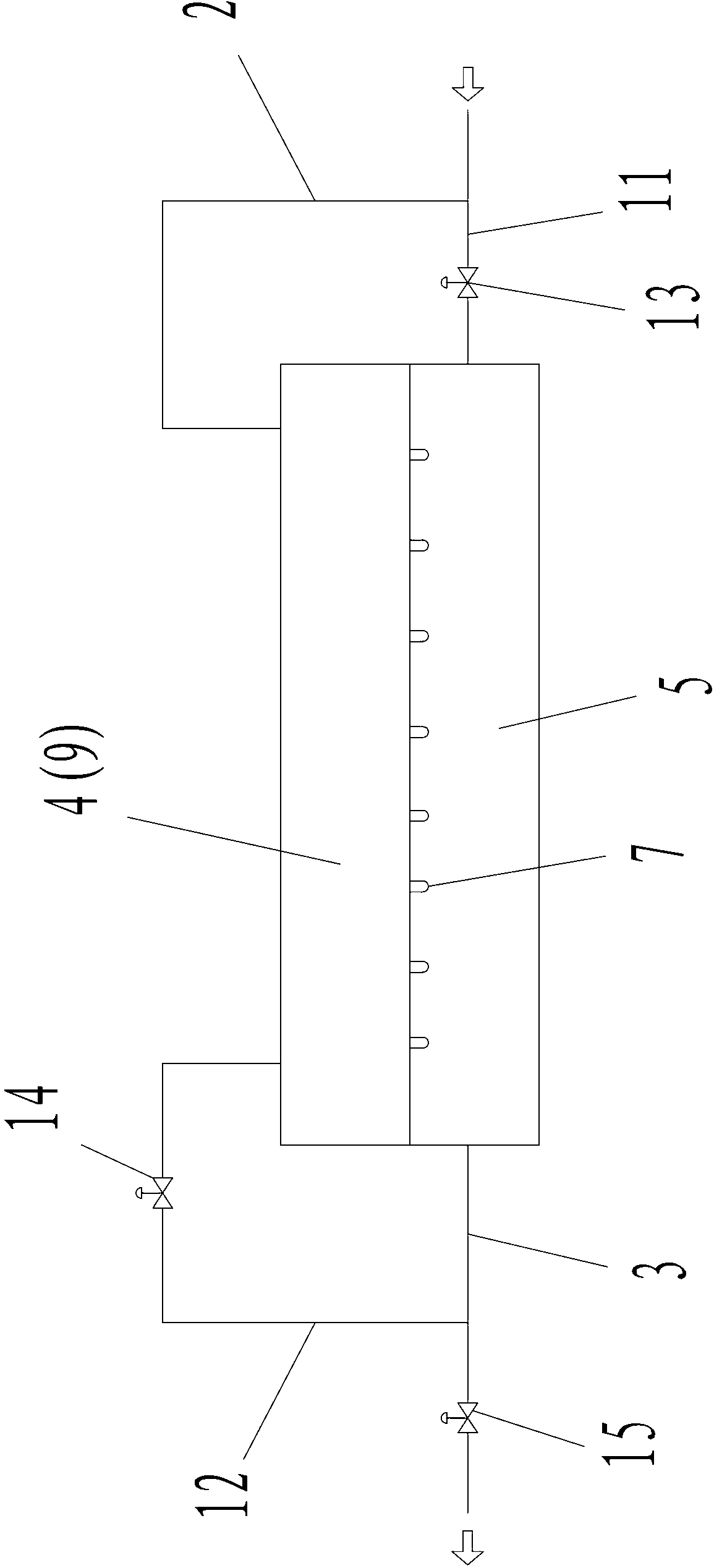

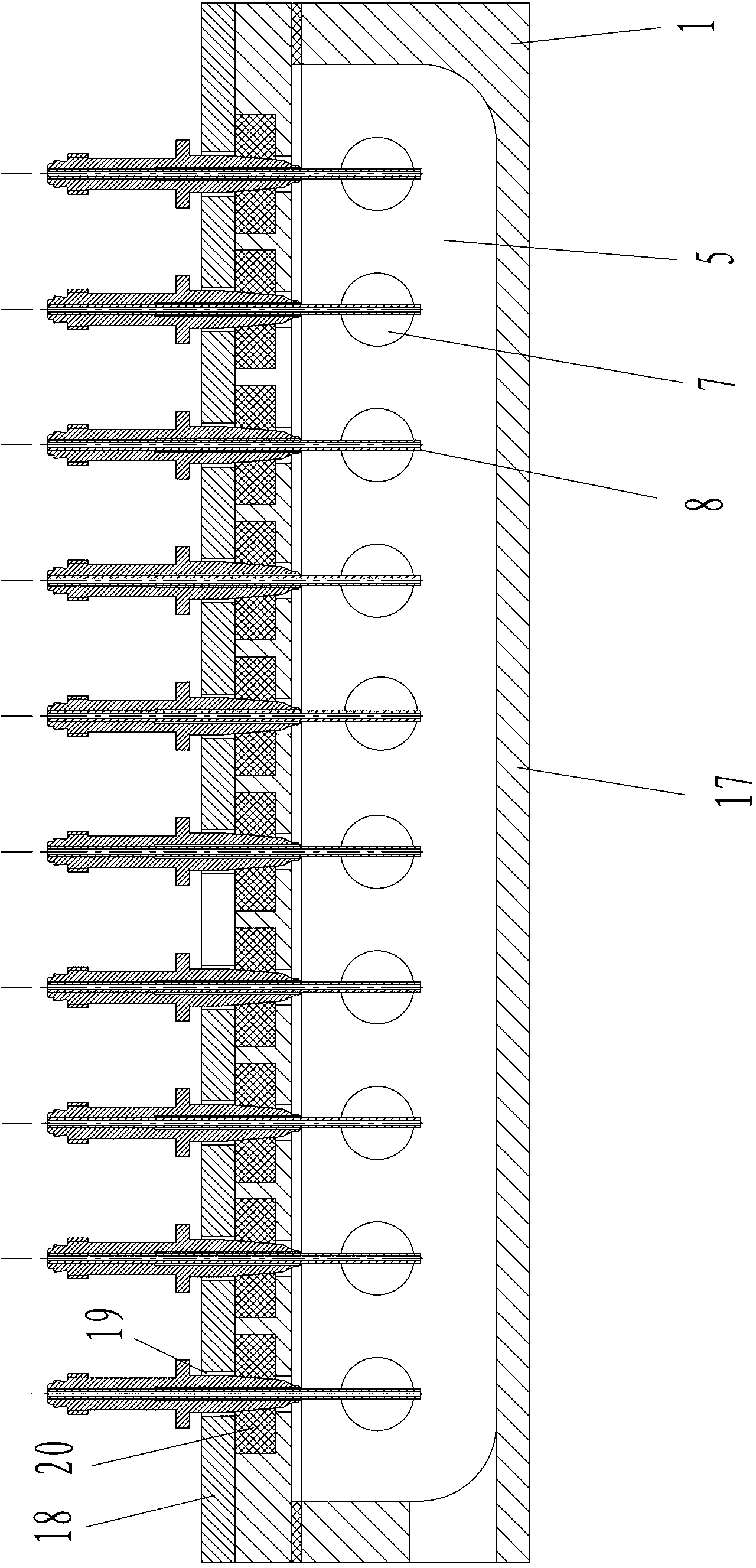

[0028] Such as Figure 1 to Figure 4 As shown, the water tank assembly for on-line cleaning and sterilization of needle irrigation in this embodiment includes a cleaning water tank 1, a cleaning medium input pipeline 2 and a cleaning medium discharge pipeline 3, and a discharge switching valve is arranged on the cleaning medium discharge pipeline 3 15. The cleaning water tank 1 is provided with a cleaning medium channel 4 and a needle irrigation chamber 5 into which the irrigation needle 8 can be inserted. The inlet end of the cleaning medium channel 4 is connected with the cleaning medium input pipeline 2 , and the outlet end of the needle irrigation cleaning chamber 5 is connected with the cleaning medium discharge pipeline 3 . The cleaning medium channel 4 is provided with a plurality of nozzles 7 leading to the needle irrigation cleaning chamber 5 along the length of the channel. The nozzles 7 face the irrigation needles 8 in the needle irrigation cleaning chamber 5 and ca...

Embodiment 2

[0034] Such as Figure 5 As shown, the water tank assembly for on-line cleaning and sterilization of needle irrigation in this embodiment includes a cleaning water tank 1, a cleaning medium input pipeline 2 and a cleaning medium discharge pipeline 3, and a discharge switching valve is arranged on the cleaning medium discharge pipeline 3 15. The cleaning water tank 1 is provided with a cleaning medium channel 4 and a needle irrigation chamber 5 into which the irrigation needle 8 can be inserted. The inlet end of the cleaning medium channel 4 is connected with the cleaning medium input pipeline 2 , and the outlet end of the needle irrigation cleaning chamber 5 is connected with the cleaning medium discharge pipeline 3 . The cleaning medium channel 4 is provided with a plurality of water passage holes 6 leading to the needle irrigation cleaning chamber 5 along the length of the passage. The water passage holes 6 face the irrigation needles 8 in the needle irrigation cleaning cham...

Embodiment 3

[0039] Such as Figure 6 As mentioned above, the water tank assembly for on-line cleaning and sterilization of irrigation needles in this embodiment is basically the same in structure as that of Embodiment 2, the difference is that the cover plate 18 is fixedly connected with the irrigation needle 8 and cleaned at the irrigation needle 8 The hour cover is arranged on the box body 17 , and the box body 17 is provided with a second sealing member 21 for sealing with the cover plate 18 . The water tank of this form has a simpler sealing structure.

[0040] In this embodiment, the box body 17 is provided with a locking mechanism 22 for locking the cover plate 18 on the box body 17 when the cover plate 18 is set on the box body 17. The locking mechanism 22 is a conventional The conventional locking structure will not be repeated here.

[0041] When filling the filling needle 8, since the cover plate 18 and the filling needle 8 are fixedly connected as one, the cover plate 18 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com