Large-scale adsorbing material ZIF-8 preparation method and forming method

A ZIF-8, adsorption material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of good repeatability and insufficient yield of synthetic methods, and achieve high crystallinity, improved yield, and good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

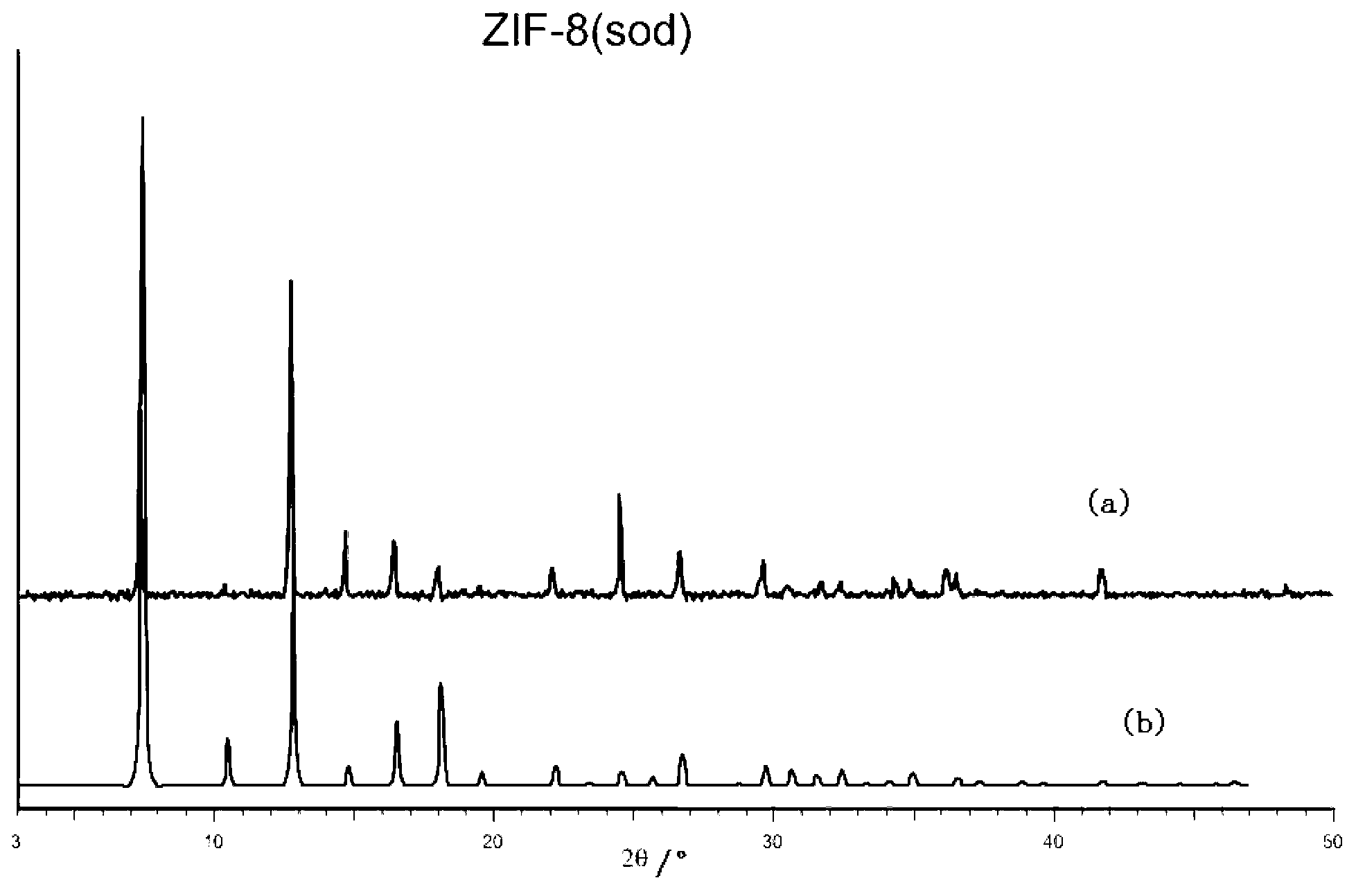

Image

Examples

Embodiment 1

[0034] Weigh 0.9556g of Zn(NO 3 ) 2 ·6H 2 O and 0.791g of 2-methylimidazole, the ratio of the amount of the two substances is approximately 1:3, and the DMF of 72ml is weighed with a measuring cylinder of 100ml. The reaction was carried out in a hydrothermal reactor with a Teflon liner. First add weighed DMF to the inner liner of polytetrafluoroethylene, then add the weighed 2-methylimidazole and Zn(NO 3 ) 2 ·6H 2 O, stir evenly with a glass rod until the crystal raw material is completely dissolved; then put the polytetrafluoroethylene lining into the hydrothermal kettle, tighten the stainless steel outer kettle, and carry out the crystallization reaction by self-generated pressure; finally, put the reaction kettle into the oven During the process, the room temperature was raised to 140°C at a rate of 5°C / min, and the temperature was kept constant for 24 hours. Suction filter the synthesized product, then in CH 3 Soak in OH solution for 48 hours, and then dry in an ove...

Embodiment 2

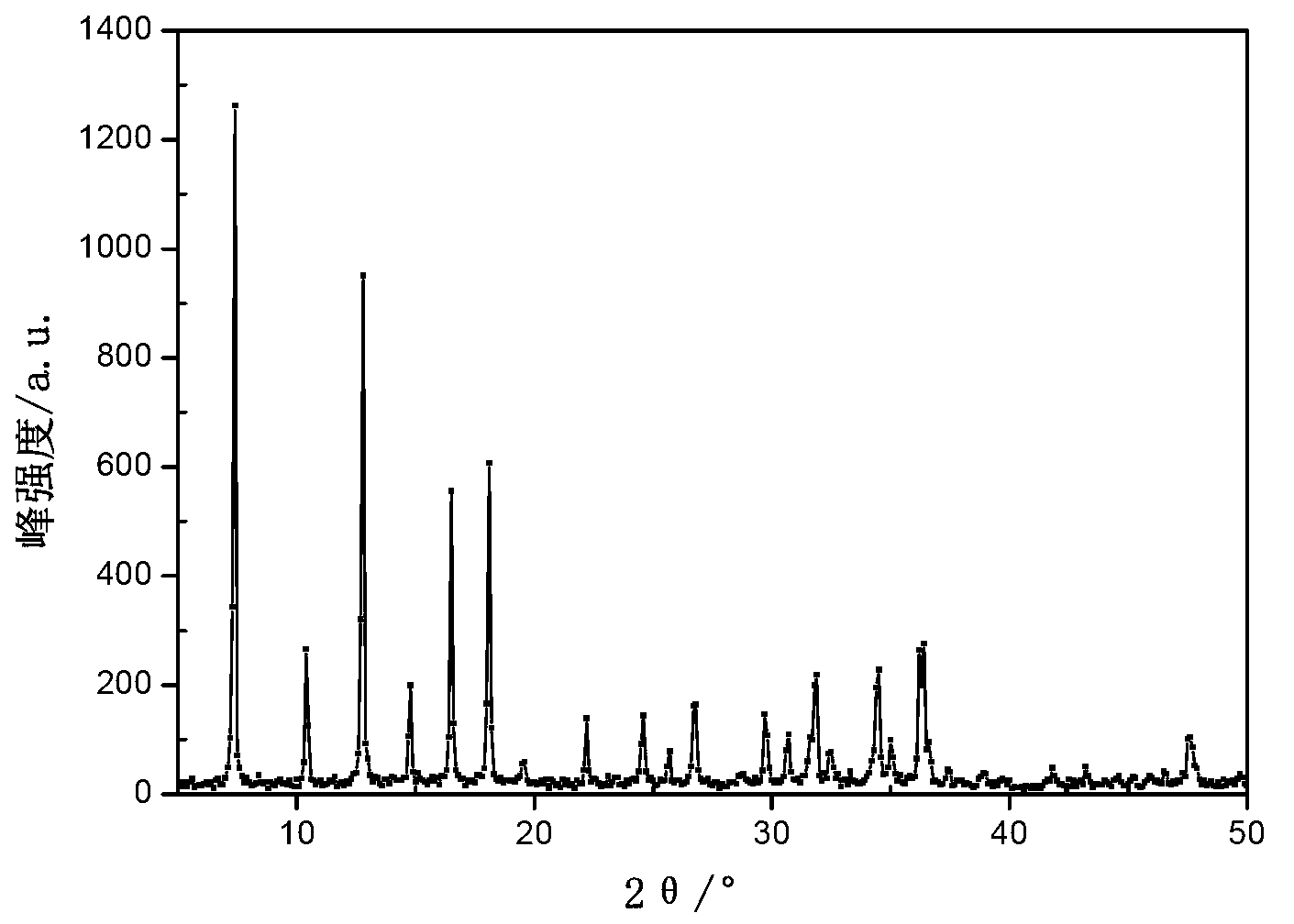

[0041] Weigh 0.5 g of the powdered material of Example 1, use trichloroacetic acid as the peptizer, and select the turnip powder as the binder, the amount of which is 10% of the original powder mass, and the amount of trichloroacetic acid is about 0.3ml. Then grind evenly, the product is carried out tabletting on the tablet machine, finally make the sheet material that radius is 0.9mm. Each molding material was characterized by BET to investigate the influence of molding conditions on the specific surface area of the sample, as shown in the attached figure 2 shown. The molded samples were characterized by XRD, and the results are shown in the attached image 3 shown.

[0042] Figure 4 It shows that the specific surface area of the molded product is reduced by 135.37m2 by adding 10% of the mass of the original powder. 2 / g, the specific surface area loss is 11.4%. It shows that the choice of molding conditions did not cause a large loss to the adsorption properties o...

Embodiment 3

[0044] Weigh 0.5 g of the powdered material of Example 1, use trichloroacetic acid as the peptizer, select methyl cellulose as the binder, the amount is 10% of the original powder mass, and the amount of trichloroacetic acid is about 0.3 ml. Then grind evenly, the product is carried out tabletting on the tablet machine, finally make the sheet material that radius is 0.9mm. Each molding material was characterized by BET to investigate the influence of molding conditions on the specific surface area of the sample, as shown in the attached Image 6 shown. The molded samples were characterized by XRD, and the results are attached Figure 7 shown.

[0045] Image 6 It shows that the specific surface area of the molded product decreases by 123.38m3 by adding methyl cellulose with 10% of the original powder mass. 2 / g, the specific surface area loss is 10.4%. It shows that the choice of molding conditions did not cause a large loss to the adsorption properties of the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com