Replaceable film filter core for PM2.5 purifying mouth mask and preparation method of filter core

A film-coated and mask technology, applied in the field of replaceable film-coated filter elements for purifying PM2.5 masks and its preparation, can solve the problems of long conveying distance, few masks, small PM2.5 particle size, etc., and achieve long service life , good air permeability, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

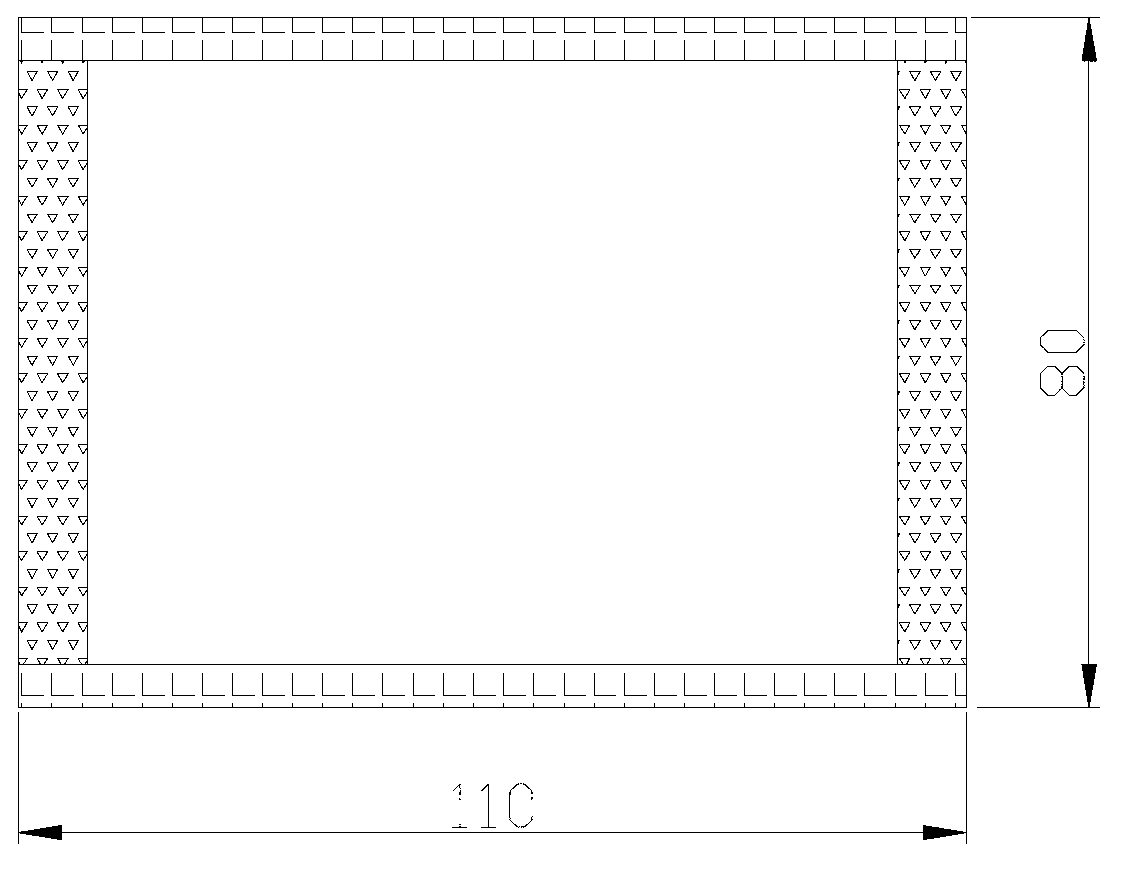

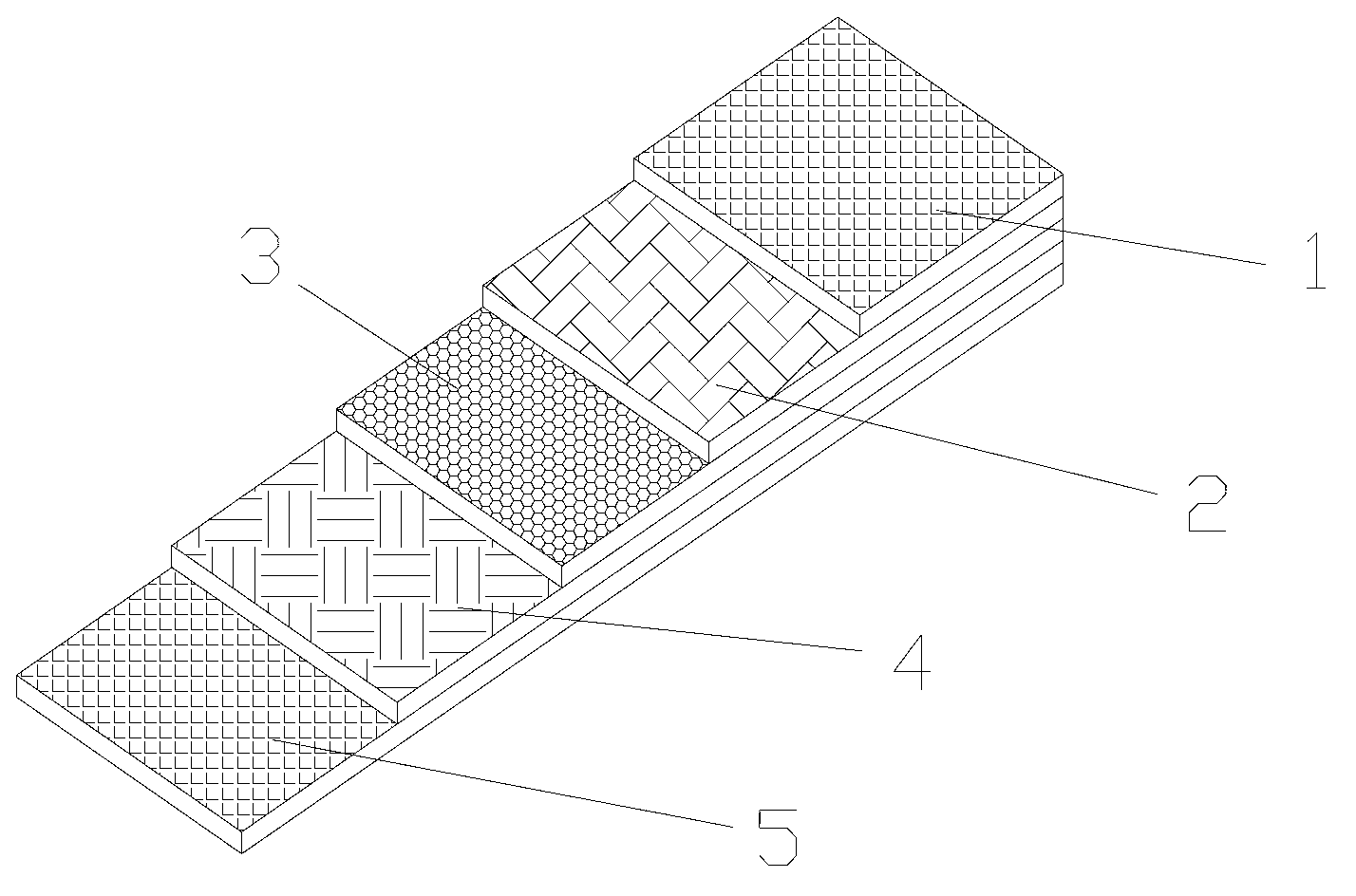

[0021] Such as figure 1 , 2 The replaceable film-coated filter element for purifying PM2.5 masks shown is composed of the first spunbonded non-woven fabric layer 1, the melt-blown non-woven fabric layer 2, the PTFE microporous membrane layer 3, and the activated carbon non-woven fabric layer from top to bottom. Layer 4 and the second spun-bonded non-woven fabric layer 5 are composited; the cross-section of the PM2.5 respirator with a replaceable film-coated filter element is rectangular, with a length of 105 cm and a width of 75 cm.

[0022] The grammage of above-mentioned first spunbond nonwoven fabric layer, melt blown nonwoven fabric layer, activated carbon nonwoven fabric layer and the second spunbond nonwoven fabric layer is 20g / m 2 ;The weight of PTFE microporous membrane is 1.0g / m 2 .

[0023] The above-mentioned PTFE microporous membrane has a pore size of 0.5 μm, a porosity of 80%, and an air permeability of 8 cm / s (127 Pa).

[0024] The above-mentioned manufactur...

Embodiment 2

[0027] Basically the same as Example 1, the difference is: the length of the PM2.5 respirator with replaceable film-covered filter element is 115cm, and the width is 85cm.

[0028] The grammage of the first spunbond nonwoven layer, melt blown nonwoven layer, activated carbon nonwoven layer and the second spunbond nonwoven layer is 30g / m 2 ;The weight of PTFE microporous membrane is 4.0g / m 2 .

[0029] The PTFE microporous membrane has a pore size of 1.0μm, a porosity of 90%, and an air permeability of 14cm / s (127Pa).

[0030] The temperature of the edge of the hot-melt seam is 160°C, and the hot-melt pressure is 0.8MPa.

[0031] The obtained replaceable film-coated filter element for purifying PM2.5 masks has a filtration efficiency of >99.97%, an air permeability of >10.0cm / s, and a filtration resistance of <150Pa. The filtration efficiency, air permeability, and filtration resistance are all tested according to GB2626-2006.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com