Disperse dyes and method for dyeing hydrophobic fiber material using same

A technology of disperse dyes and fiber materials, applied in the field of dye compositions, can solve the problems of fading, unbalanced light fastness, unbalanced dyeing characteristics, etc., and achieve the effect of strong light fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: the manufacture of disperse dye composition

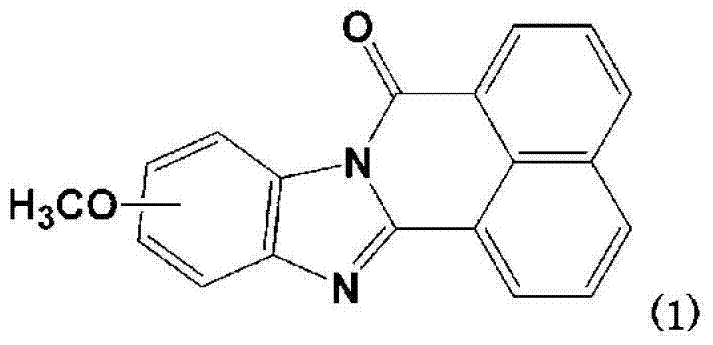

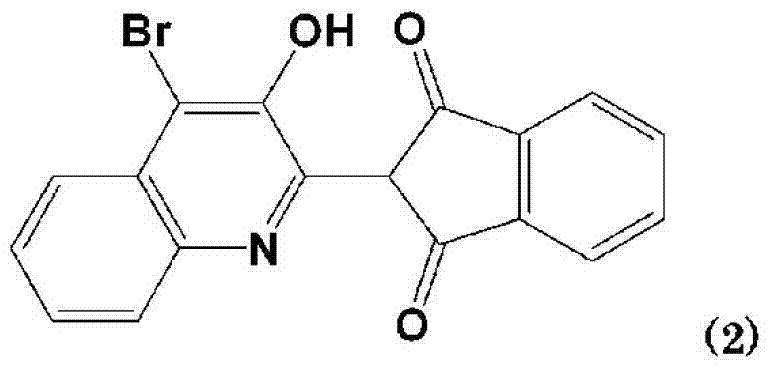

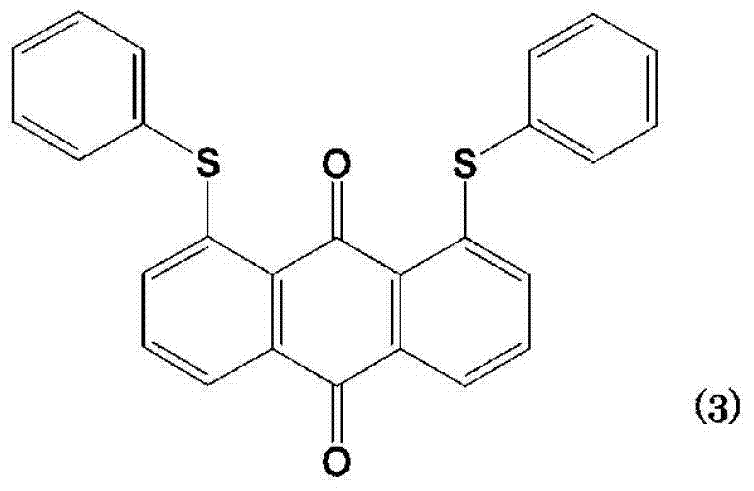

[0077] To 5.0% of the raw material powder represented by the formula (1), 1.6% of the raw material powder represented by the formula (2) and 26.0% of the raw material powder represented by the formula (3), a dispersant in an amount of 67.4% was added, and then It was pulverized to produce a yellowish disperse dye composition.

[0078] A dispersant in an amount of 65.0% was added to 7.5% of the raw material powder represented by formula (6) and 27.5% of the raw material powder represented by formula (7), which were then pulverized to produce a red-based disperse dye composition.

[0079] A dispersant in an amount of 75.4% was added to 22.5% of the raw material powder represented by formula (8) and 2.1% of the raw material powder represented by formula (9), which were then pulverized to produce a blue-based disperse dye composition.

Embodiment 2

[0080] Embodiment 2: the manufacture of disperse dye composition

[0081] To 6.0% of the raw material powder represented by the formula (1), 1.6% of the raw material powder represented by the formula (2), 12.0% of the raw material powder represented by the formula (4) and 4.9% of the raw material powder represented by the formula (5) The raw material powder was added with a dispersant in an amount of 75.5%, and then pulverized to produce a yellow-based disperse dye composition.

[0082] A dispersant in an amount of 65.0% was added to 7.5% of the raw material powder represented by formula (6) and 27.5% of the raw material powder represented by formula (7), which were then pulverized to produce a red-based disperse dye composition.

[0083] A dispersant in an amount of 75.4% was added to 22.5% of the raw material powder represented by formula (8) and 2.1% of the raw material powder represented by formula (9), which were then pulverized to produce a blue-based disperse dye compos...

Embodiment 3

[0085] In pure water, the yellow disperse dye composition of 0.570% o.w.f. in Example 1, the red disperse dye composition of 0.370% o.w.f. and the blue disperse dye composition of 0.400% o.w.f. are prepared with acetic acid and sodium acetate To pH 4.5, 2.0% o.w.f. of an ultraviolet absorber (SUNLIFE LPX-50, manufactured by Nicca Chemical Co., Ltd.) was added thereto to prepare 2000 parts of a dyeing bath. In a dyeing bath, soak 100 parts polyester fleece fabric (use 0.3 denier yarn on the front side and 3 denier yarn on the back side) and dye at 135°C for 30 minutes. The dyed article was then prepared in a bath consisting of 6 parts of 45% caustic soda, 6 parts of bisulfite, 3 parts of Sunmol RC-700 (anionic surfactant manufactured by Nicca Chemical Co., Ltd.) and adding water In a bath of a total amount of 3000 parts, reduction cleaning was performed at 80° C. for 10 minutes, washed with water, and then dried to produce a beige-dyed article. The dyed article thus obtained w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com