Energy storage element, metal component, and energy storage element manufacturing method

A technology for electric storage components and metal parts, applied in the direction of electrical components, structural parts, battery pack parts, etc., can solve the problems of reduced mechanical strength of protrusions, difficult processing, and difficult processing of protrusions, etc., to achieve reduction The effect of shape change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0070] In the present embodiment, an electric storage element in which metal fittings having protrusions are used as a part of the housing is mainly shown.

[0071] As an electric storage element, a nonaqueous electrolyte secondary battery (specifically, a lithium ion battery) which is one example of a secondary battery will be described as an example.

[0072] Furthermore, the so-called power storage element is used in a broad concept including a secondary battery or a capacitor, which is an element (device) that can be charged and discharged.

[0073] (Configuration of storage device 100 (nonaqueous electrolyte secondary battery))

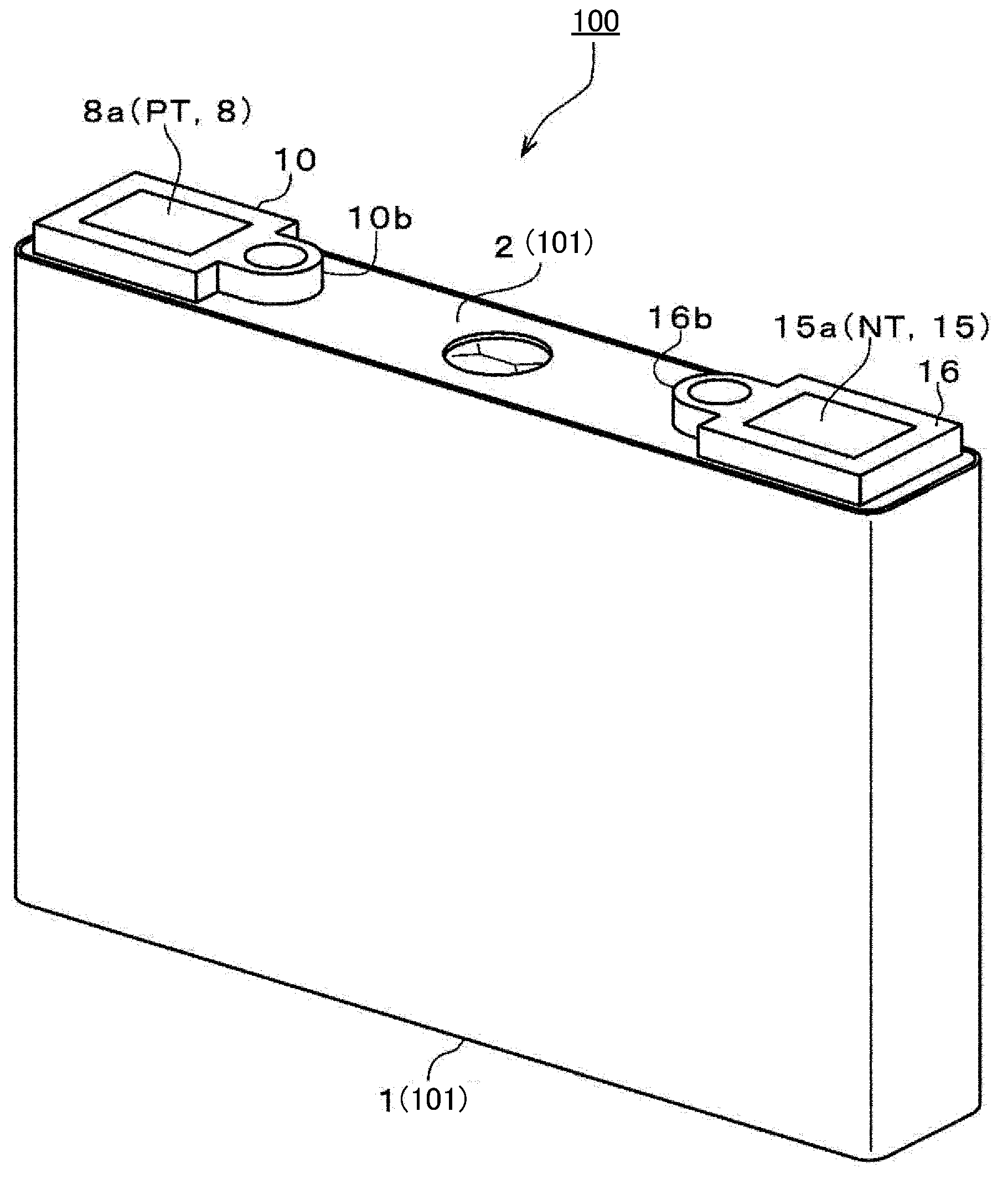

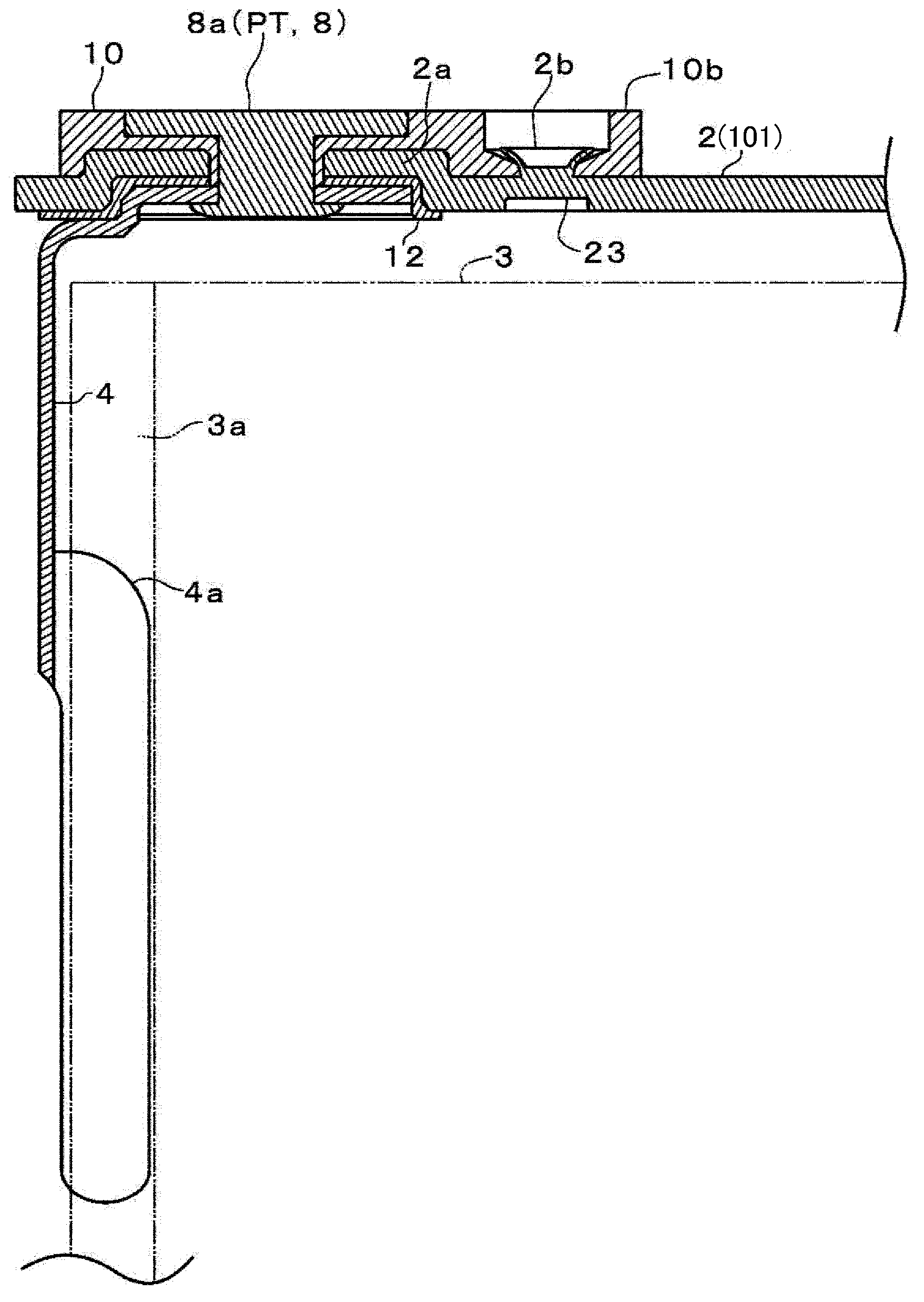

[0074] Such as figure 1 as well as figure 2 As shown, the storage device 100 of the present embodiment has a frame body 101 composed of a bottomed cylindrical (more specifically, bottomed rectangular cylindrical) can body 1 and a case that clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com