Pneumatic tire

A technology of pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, heavy-duty tires, special tires, etc., can solve tire difficulties and other problems, and achieve the effects of suppressing groove cracking, significant groove cracking resistance, and strain reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

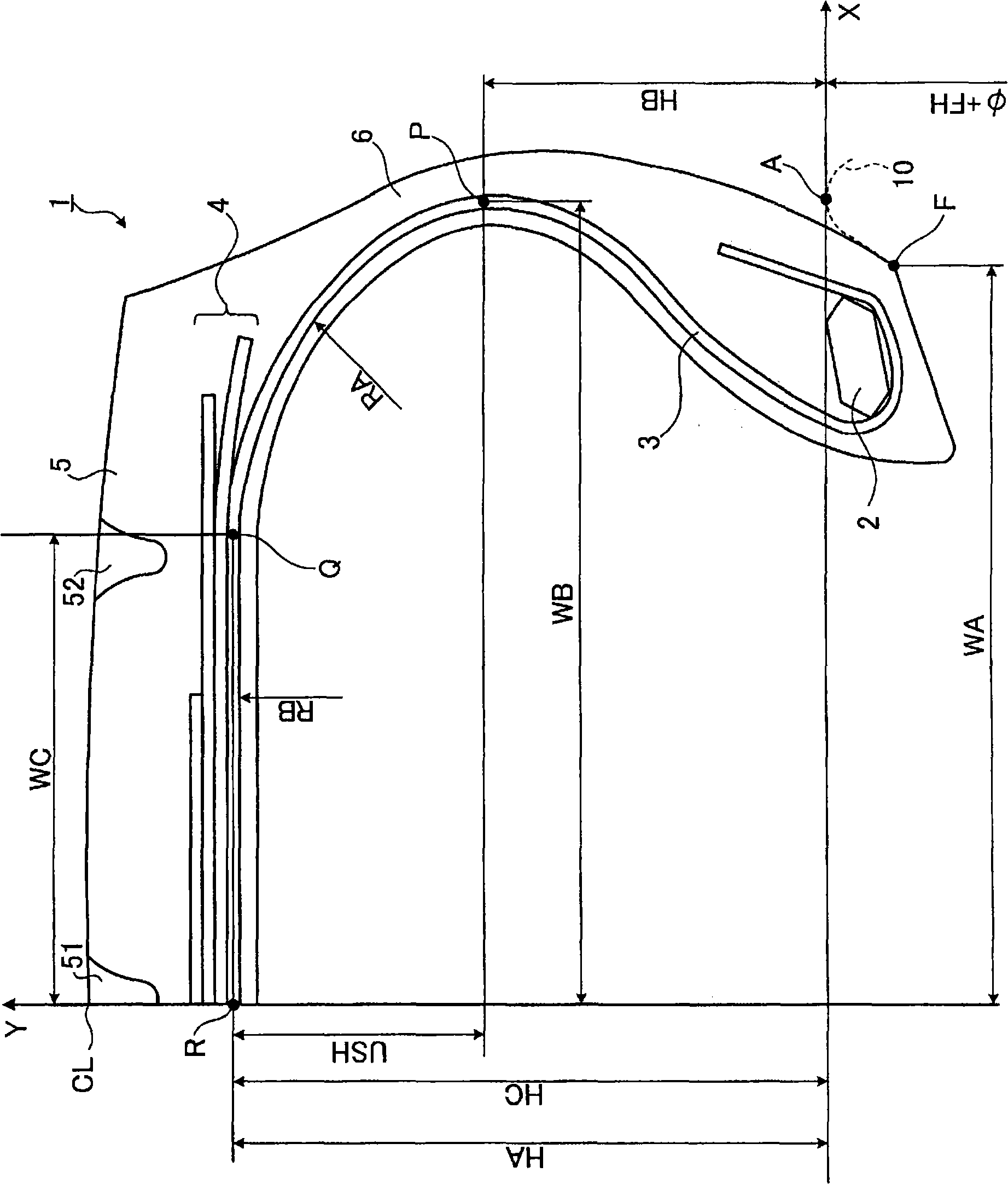

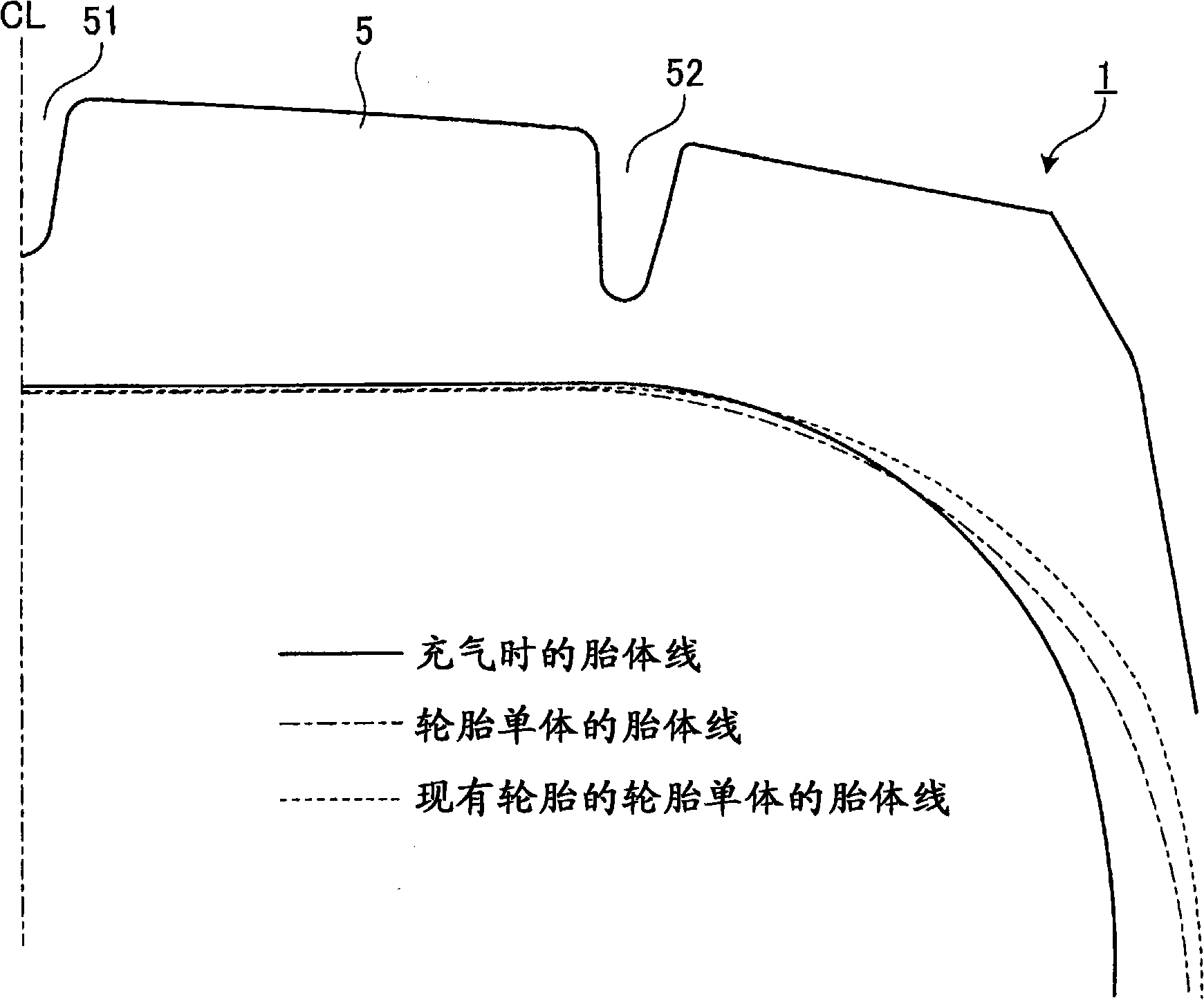

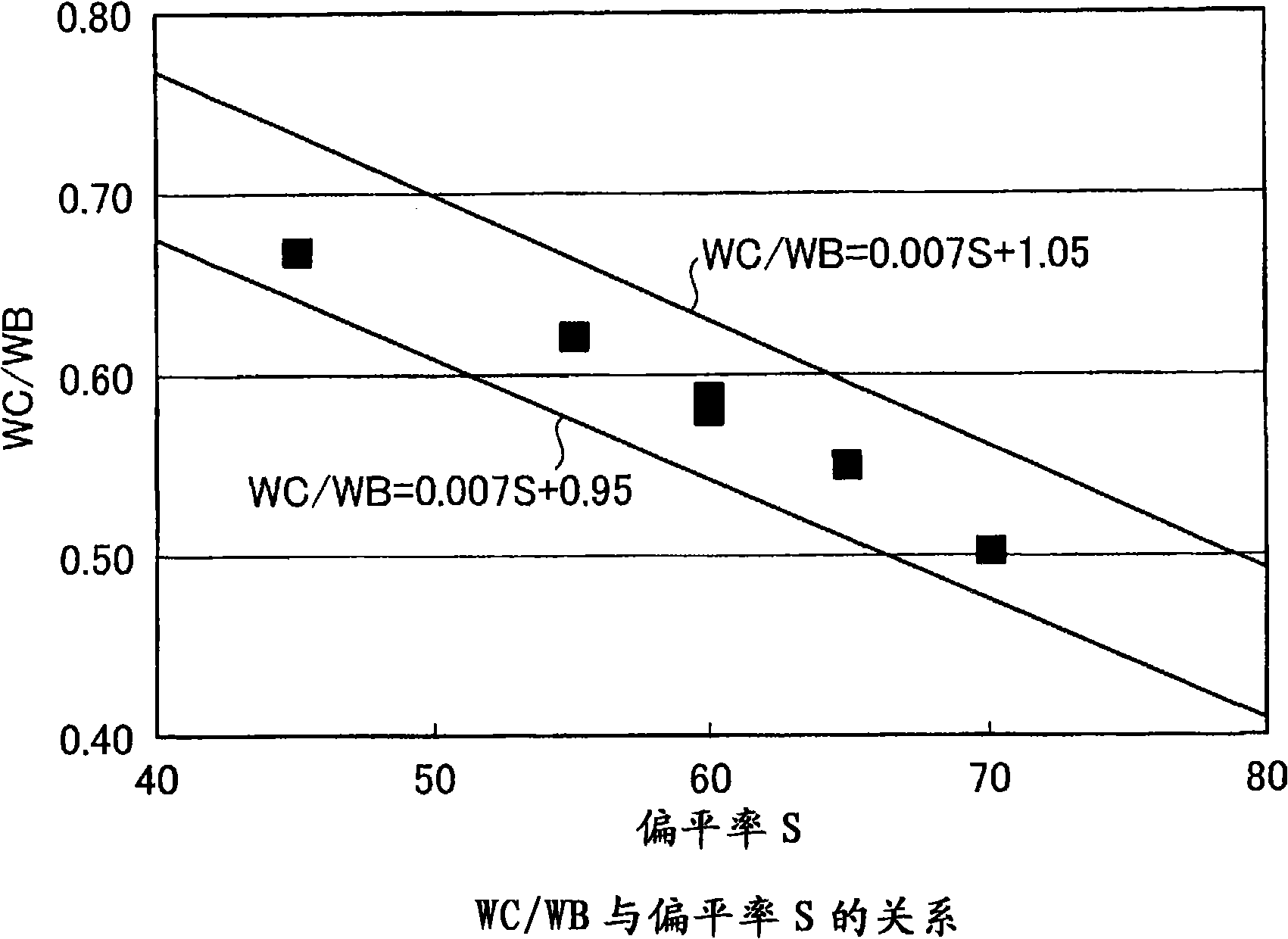

[0048] figure 1 It is a sectional view showing the tire meridian direction of the pneumatic tire according to Example 1 of the present invention. figure 2 yes means figure 1 An explanatory diagram of the action of the described pneumatic tire. image 3 as well as Figure 4 yes means figure 1 This is a different graph of the described pneumatic tire due to each aspect ratio. Figure 5 as well as Figure 6 It is a graph showing the results of performance tests of pneumatic tires according to Examples of the present invention.

[0049] [Pneumatic tire]

[0050] Pneumatic tire 1 comprises: bead core 2, carcass ply 3, belt layer 4, tread rubber 5 and sidewall rubber 6 (refer to figure 1 ). The bead core 2 has an annular structure, and a pair of left and right bead cores 2 constitute a set. The carcass ply 3 is spanned annularly between the left and right bead cores 2 , 2 to constitute a skeleton (structure) of the tire. The belt layer 4 is composed of a plurality of lami...

Embodiment 2

[0073] Figure 7 It is a graph showing the difference due to each aspect ratio of the pneumatic tire according to Example 2 of the present invention. Figure 8 It is an explanatory diagram showing a carcass thread of a pneumatic tire according to Example 2 of the present invention. Figure 9 It is an explanatory diagram showing the operation of the pneumatic tire according to the second embodiment of the present invention. Figure 10 as well as Figure 11 It is a graph showing the results of performance tests of pneumatic tires according to Examples of the present invention.

[0074] In the pneumatic tire 1 of this Example 2, compared with the pneumatic tire 1 of Example 1, it is characterized in that, in the cross-sectional shape (carcass line) of the carcass ply 3 viewed from a section in the tire meridian direction, a predetermined The size ratios USH / HA, WB / HA, WC / WB are defined by a predetermined quadratic approximation.

[0075] Specifically, first, the distance USH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com