Large-area bonding structure of semiconductor substrate and manufacturing method thereof

A semiconductor and large-area technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as high process temperature and pressure, low yield rate, and application limitations of bonding LED technology, so as to improve yield rate , reduce requirements, reduce the effect of pressure and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

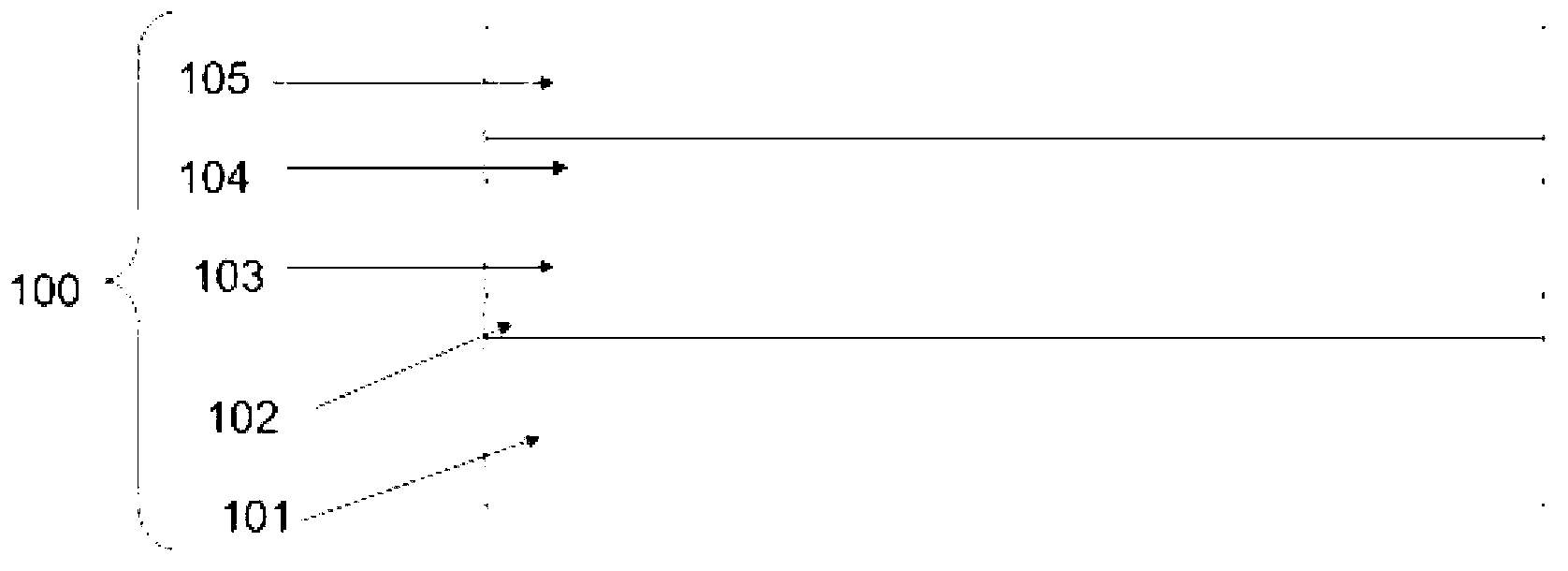

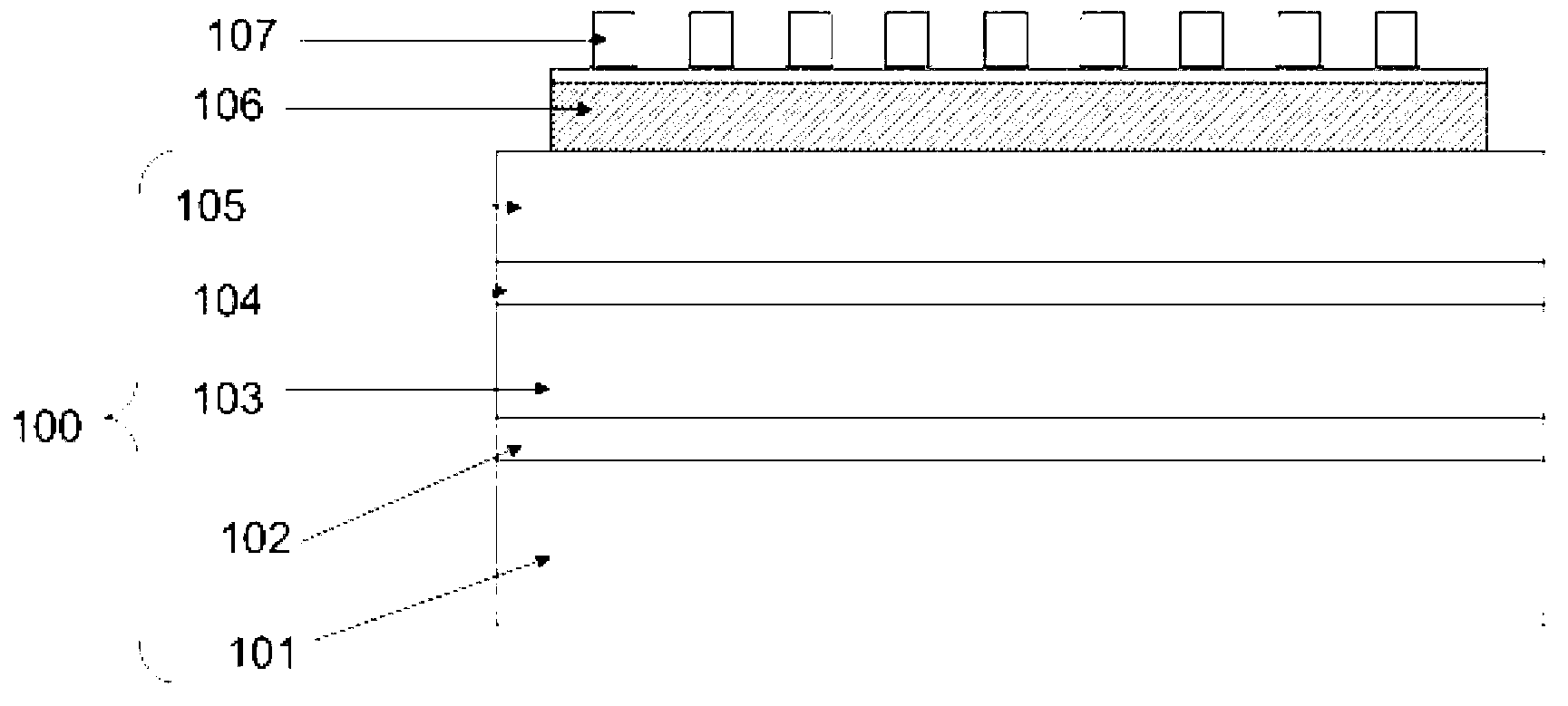

[0059] Specific embodiment 1 is applied to the large-area bonding process of quaternary light-emitting diodes. Usually, the substrate used for quaternary light-emitting diodes is a gallium arsenide substrate 101, and a gallium arsenide buffer is epitaxially grown on the gallium arsenide substrate. Layer 102; growing the first conductive type semiconductor layer 103 includes: n-type gallium arsenide layer, n-type InGaP corrosion stop layer, n-type doped InGaAlP layer; growing multi-quantum well light-emitting active layer 104; growing the second conductive type Semiconductor layer 105: p-type doped InGaAlP, p-type doped GaP. So far, the growth of the quaternary LED epitaxial wafer is completed. In order to perform the subsequent bonding process, a contact layer 106 is prepared on the second conductivity type semiconductor layer 105, which forms an ohmic contact with the second conductivity type semiconductor layer, and the metal forming the contact layer preferably includes Ti,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com