Dam face energy dissipation tool

A technology of energy dissipation and dam surface, which is applied in water conservancy projects, sea area engineering, coastline protection, etc. It can solve the problem of not reflecting the step energy dissipation of the dam surface, the inability to form a stable slipping water flow, and reducing the engineering volume of downstream stilling pools, etc. problems, to achieve the effect of improving the energy dissipation efficiency of the dam surface, increasing energy dissipation, and reducing the impact of slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

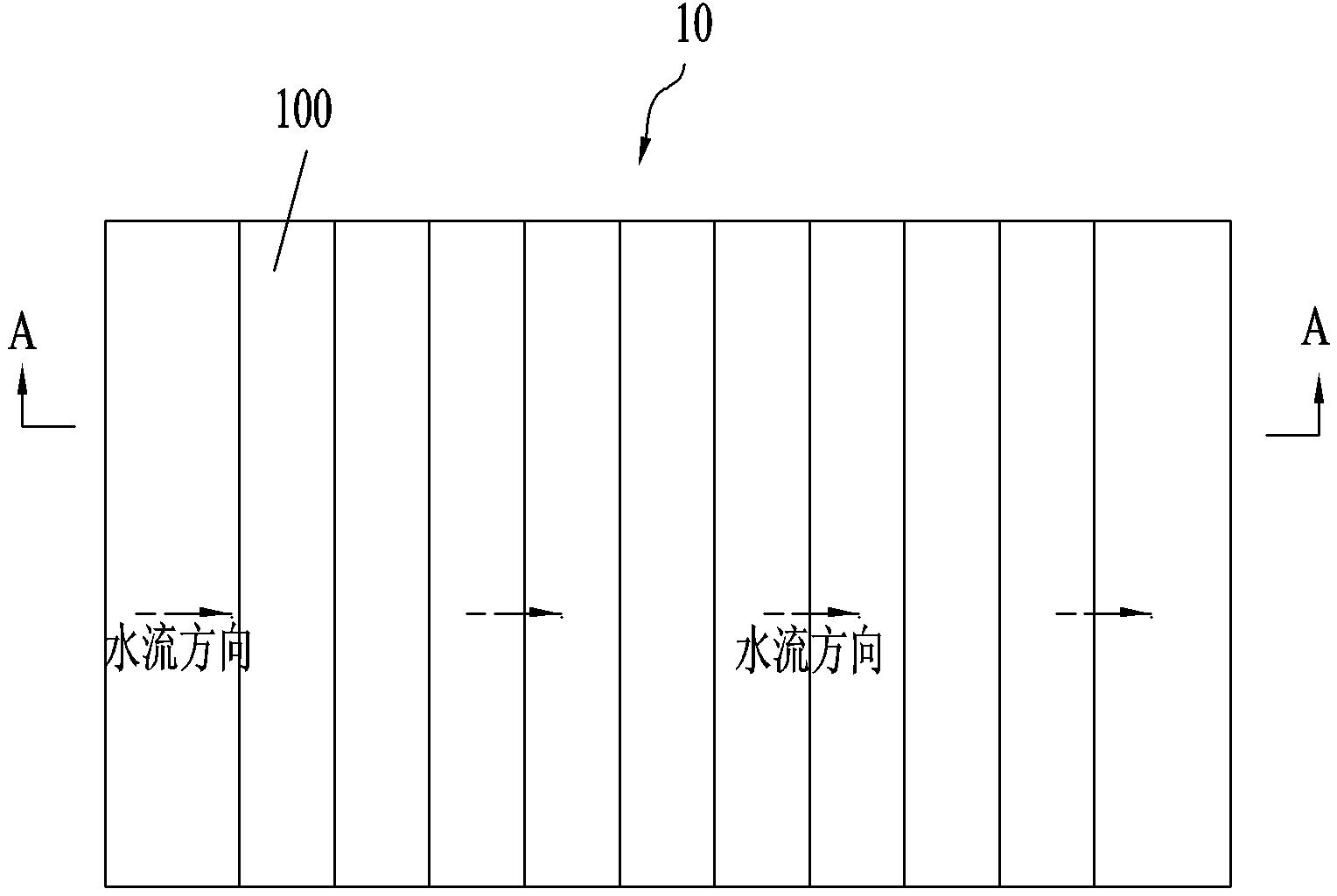

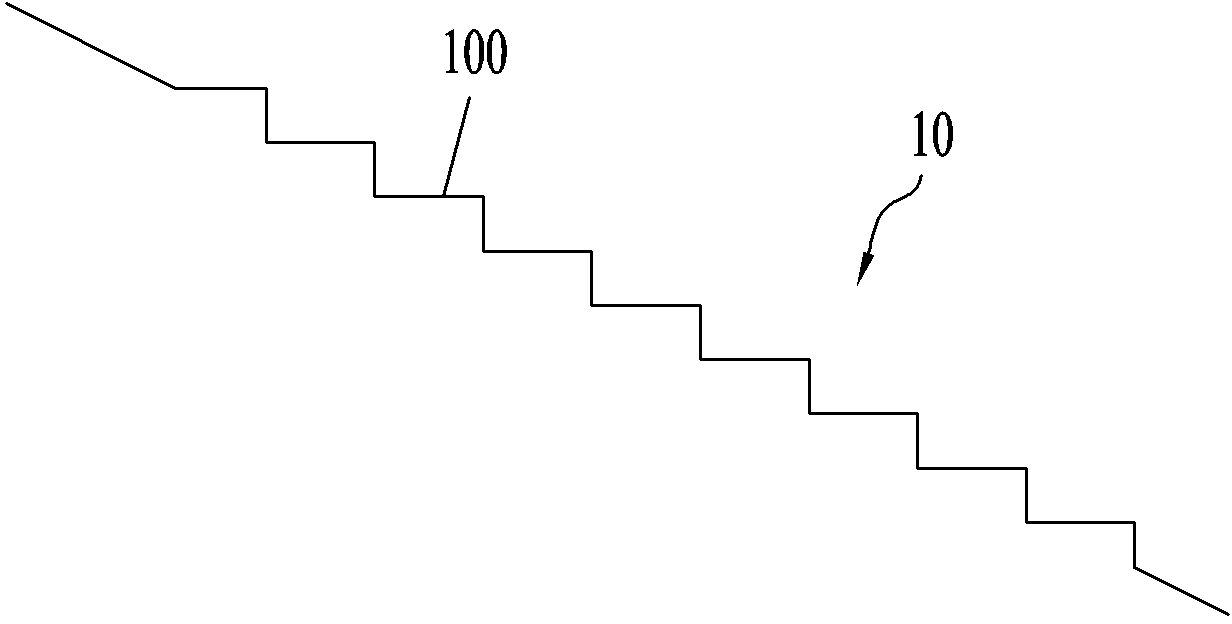

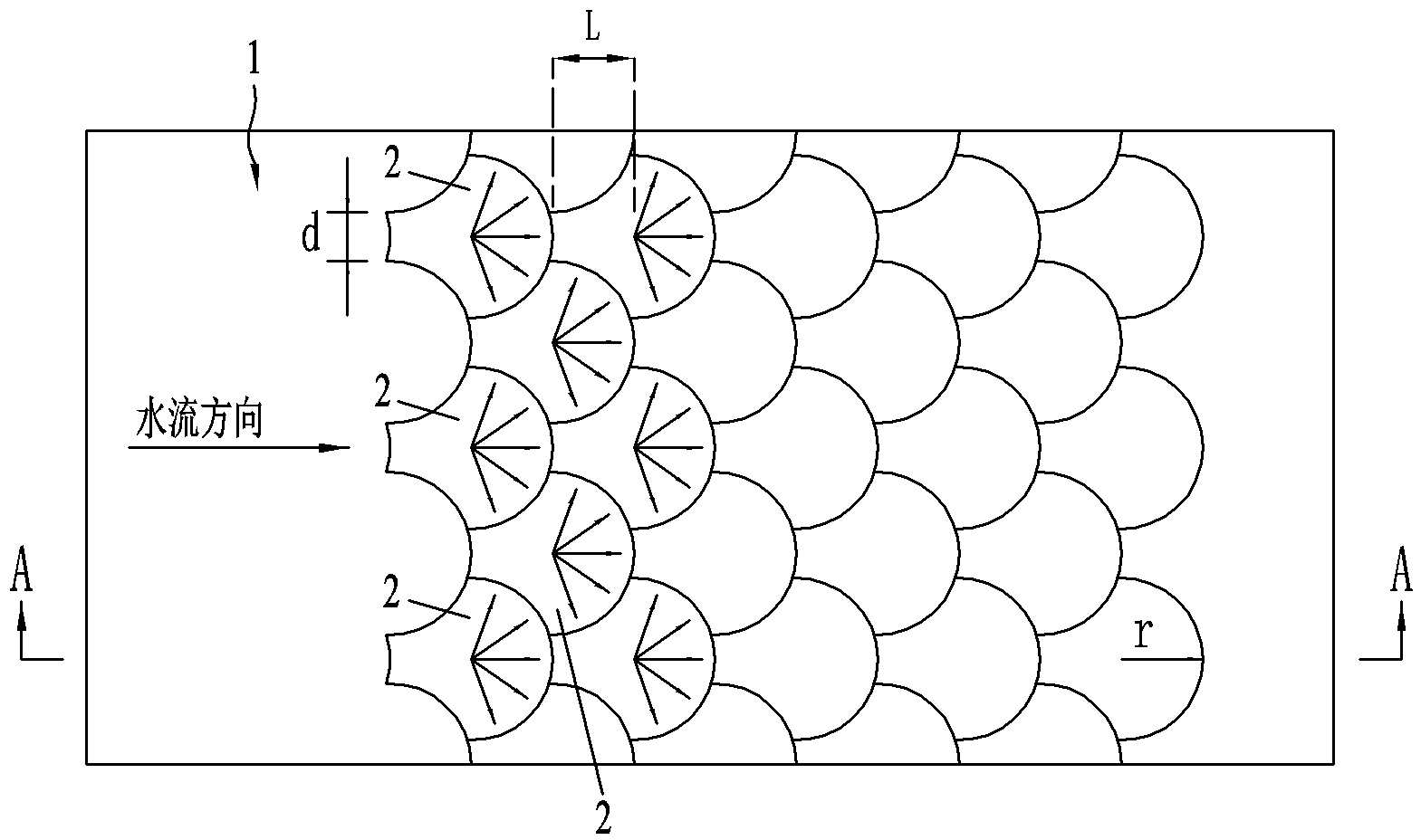

[0012] Such as image 3 , Figure 4 As shown, the dam surface energy dissipator includes a slanted dam surface 1 with a certain length, and the dam surface 1 is distributed with multiple groups of bosses in a stepped manner from top to bottom, and the adjacent bosses are distributed in dislocation. Nested in the shape of fish scales, the top surface of each boss 2 is tilted up from front to back, and the rear edge is arc-shaped, which can effectively increase aeration compared with the existing straight stepped energy dissipator The length increases the contact surface between water flow and air, so that the surface of the discharge tongue is more fully aerated, and the air-filled swirl at the bottom edge is more stable and complete. The top surface of the boss 2 is tilted backward to form a slightly concave area, just like a miniature stilling pond , the water cushion formed can reduce the impact of falling flow and prevent cavitation on the dam surface; when the flood is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com