Glabridin molecularly imprinted polymer, as well as preparation method and application thereof

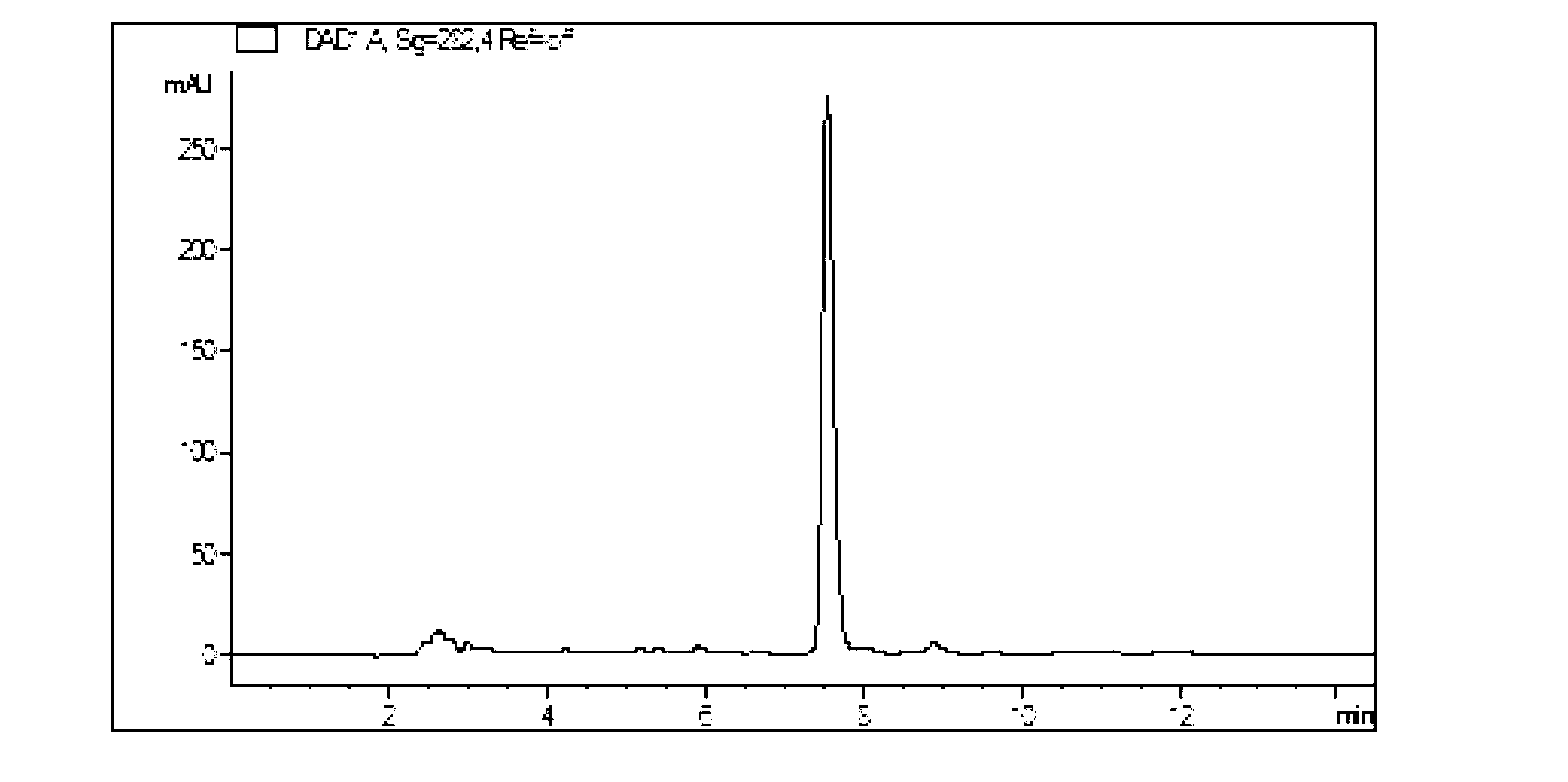

A technology of glabridin and molecular imprinting, which is applied to chemical instruments and methods, ion exchange, and other chemical processes, can solve the problems of unreported preparation methods and unreported extraction and purification of glabridin molecular imprinting, and achieve good results. The effect of process stability and controllability, strong selectivity and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) material preparation

[0031] The components of this embodiment are formulated according to the following dosage ratio: template molecule (glabridin) 0.97g, functional monomer (methacrylic acid) 1.63g, crosslinking agent (ethylene glycol dimethacrylate) 19.00g, 0.10 g of initiator (azobisisobutyronitrile), 42.00 g of solvent (mixed solvent with a weight ratio of acetonitrile and chloroform of 1:1).

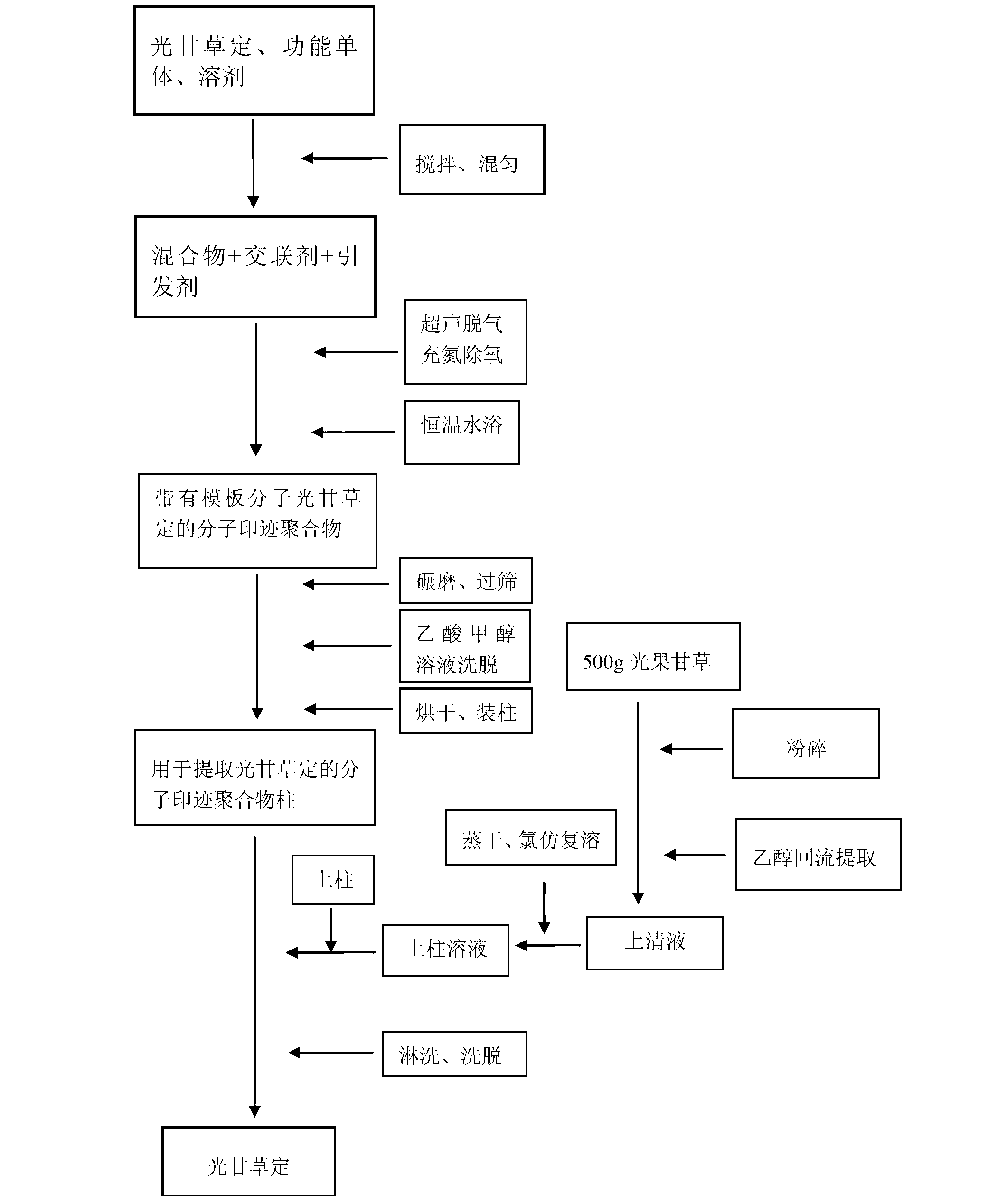

[0032] (2) Preparation of molecularly imprinted polymers with the template molecule glabridin

[0033] Add the mixed solvent of template molecule glabridin, methacrylic acid, ethylene glycol dimethacrylate, azobisisobutyronitrile, acetonitrile and chloroform prepared in (1) into the reaction kettle and mix evenly, and ultrasonically degas 15min, then filled with nitrogen to remove oxygen, sealed and polymerized in a constant temperature water bath at 60°C for 24 hours to obtain a molecularly imprinted polymer with template molecule glabridin, and then grind it through ...

Embodiment 2

[0040] (1) material preparation

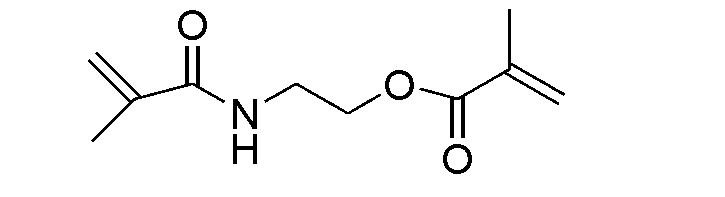

[0041] The components of this example are formulated according to the following dosage ratio: template molecule (glabridin) 0.97g, functional monomer (4-vinylpyridine) 1.83g, crosslinking agent (N,N-dimethylbisacrylamide ) 21.00g, initiator (azobisisobutyronitrile) 0.16g, solvent (N,N-dimethylformamide and chloroform in a weight ratio of 2:1 mixed solvent) 45.00g.

[0042] (2) Preparation of molecularly imprinted polymers with the template molecule glabridin

[0043] Prepare template molecule glabridin, 4-vinylpyridine, N,N-dimethylbisacrylamide, azobisisobutyronitrile, N,N-dimethylformamide and chloroform Add the mixed solvent into the reaction kettle and mix evenly, ultrasonically degas for 15 minutes, then fill with nitrogen to remove oxygen, seal and polymerize in a constant temperature water bath at 60°C for 24 hours to obtain a molecularly imprinted polymer with template molecule glabridin, and then grind it After passing through 100-m...

Embodiment 3

[0050] (1) material preparation

[0051] The components of this embodiment are formulated according to the following dosage ratio: template molecule (glabridin) 0.97g, functional monomer (vinylimidazole) 1.60g, crosslinking agent (ethylene glycol dimethacrylate) 21.00g, 0.16 g of initiator (benzoyl peroxide), 42.00 g of solvent (mixed solvent with a weight ratio of tetrahydrofuran and chloroform of 2:1).

[0052] (2) Preparation of molecularly imprinted polymers with the template molecule glabridin

[0053] Add the mixed solvent of template molecule glabridin, vinylimidazole, ethylene glycol dimethacrylate, azobisisobutyronitrile, tetrahydrofuran and chloroform prepared in (1) into the reaction kettle and mix evenly, and degas it by ultrasonic 15min, then filled with nitrogen and deoxygenated, sealed and polymerized in a constant temperature water bath at 60°C for 24 hours to obtain a molecularly imprinted polymer with template molecule glabridin, which was then ground throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Purity | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com