Preparation method for alpha-alumina supported nickel phosphide catalyst

An alumina-loaded, nickel-phosphide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult to treat phosphorus-containing wastewater, complicated implementation process, etc., and achieve no three-waste formation. , Simple steps, good feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

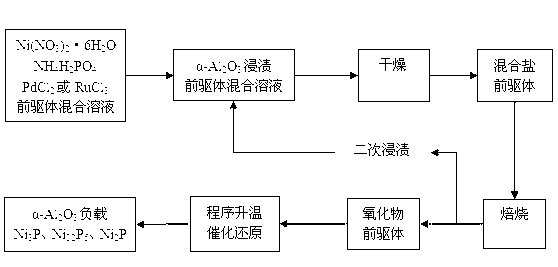

[0030] Such as figure 1 As shown, the α-alumina supported nickel phosphide catalyst (Ni 2 P) a preparation method comprising the steps of:

[0031] The first step, preparation of impregnation solution: PdCl 2 Mixed Ni(NO 3 ) 2 ·6H 2 O, NH 4 h 2 PO 4 , dissolved in ultrapure water, so that the prepared solution [Ni 2+ ] is 3.0mol / L, [Pd 2+ ] is 0.05 mol / L, P / Ni molar ratio in the precursor=0.8;

[0032] The second step, equal volume impregnation: under vacuum or normal pressure, α-Al 2 o 3 The equal volume of 50g of carrier is immersed in 25ml of impregnating solution;

[0033] The third step, drying: drying at 60°C for 6 hours;

[0034] The fourth step, roasting: roasting at 500°C for 3 hours;

[0035] The fifth step, the second procedure: immerse the prepared precursor in 25ml of immersion solution again in equal volume, and then repeat steps 3 to 4;

[0036] The sixth step, reduction: reduction in hydrogen at atmospheric pressure, the temperature condition is ...

Embodiment 2

[0039] Such as figure 1 As shown, the α-alumina supported nickel phosphide catalyst (Ni 12 P 5 Type) preparation method, the same steps as in Example 1 will not be repeated, the difference is:

[0040] The first step, preparation of impregnation solution: PdCl 2 Mixed Ni(NO 3 ) 2 ·6H 2 O, NH 4 h 2 PO 4 , dissolved in ultrapure water, so that the prepared solution [Ni 2+ ] is 3.0mol / L, [Pd 2+ ] is 0.05 mol / L, and the P / Ni molar ratio in the precursor is 0.5.

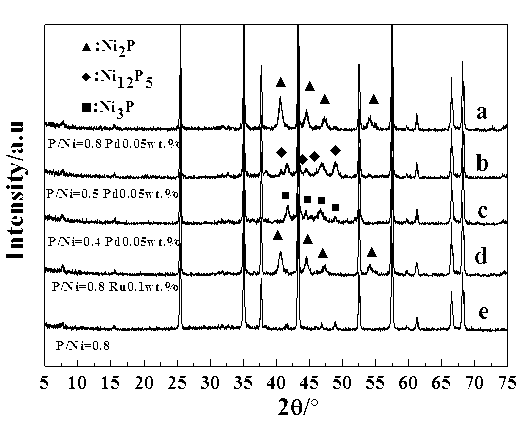

[0041] The XRD figure of nickel phosphide made in the present embodiment is as follows figure 2 As shown by the b line in the middle, the crystal phase of nickel phosphide is Ni 12 P 5 , calculated by the Scherrer formula, the particle size is <15nm, and the Pd content of the catalyst is 0.05 wt.%.

Embodiment 3

[0043] Such as figure 1 As shown, the α-alumina supported nickel phosphide catalyst (Ni 3 P type) preparation method, the same steps as in Example 1 will not be repeated, the difference is:

[0044] The first step, preparation of impregnation solution: PdCl 2 Mixed Ni(NO 3 ) 2 ·6H 2 O, NH 4 h 2 PO 4 , dissolved in ultrapure water, so that the prepared solution [Ni 2+ ] is 3.0mol / L, [Pd 2+ ] is 0.05 mol / L, and the P / Ni molar ratio in the precursor is 0.4.

[0045] The XRD pattern of nickel phosphide made in this embodiment is shown in figure 2 As shown by the line c in the middle, the crystal phase of nickel phosphide is Ni 3 P, the particle size calculated by the Scherrer formula is <15nm, and the Pd content of the catalyst is 0.05 wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com